Submitted by Ka Ki Lee

3D concrete printing expands to world construction

France Architecture News - Feb 09, 2017 - 14:36 21440 views

VINCI Construction, the largest construction company in the world by revenue, has signed a partnership agreement with XTreeE, a French startup on 3D Concrete Printing. This partnership is going to expand 3D printing technologies in construction.

XTreeE is an innovative French start-up focusing on 3D printing and digital fabrication, aiming at bringing together the construction field with the new computation design world. Led by Philippe Morel, founder of EZCT Architecture & Design Research, the team explored 3D concrete printing with ABB Robots, HAL Robotics and LafargeHolcim. After 3 years of collaboration, the start-up XTreeE is launched. The technique allows a more precise and low-waste construction process.

See latest projects of XTreeE below:

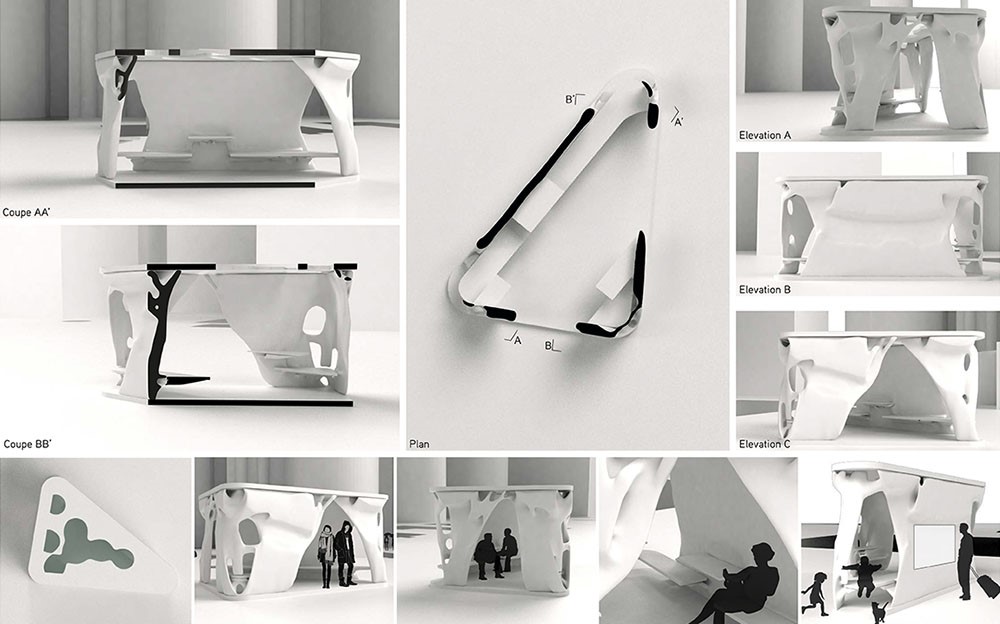

De Facto Competition-Proposal for urban furniture (2015)

Competition Entry for De Facto urban furniture competition. The proposed 3D printed, self-supported concrete structure is a single volume with openings and seats in different sizes, which allows flexibilities in function.

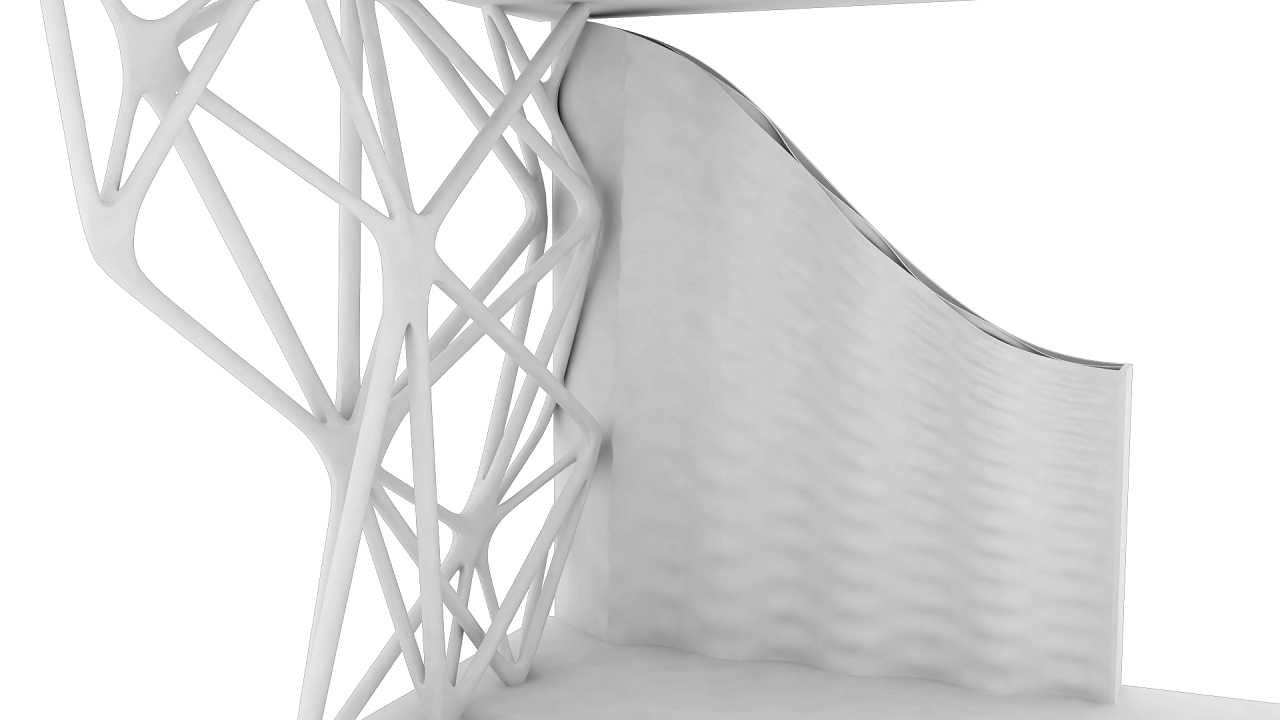

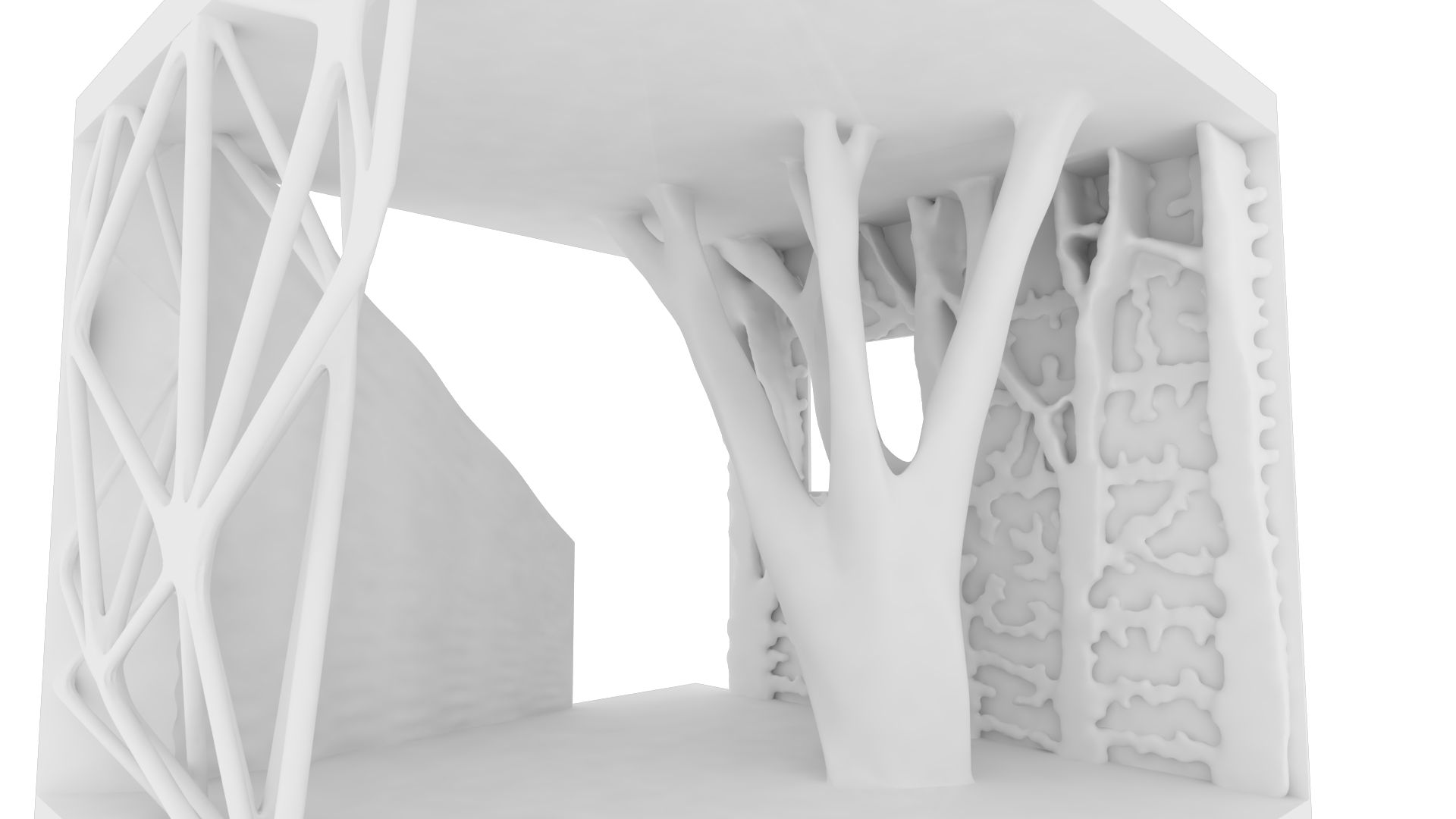

Demonstrator Pavilion (2015)  Demonstrator of different fabrication techniques XTreeE has developed. XtreeE explored different possibilities of large scaled 3D print such as printing in different directions. Except the traditional approach of printing horizontally and lifting up the wall, they also researched in printing the wall directly in the vertical position.

Demonstrator of different fabrication techniques XTreeE has developed. XtreeE explored different possibilities of large scaled 3D print such as printing in different directions. Except the traditional approach of printing horizontally and lifting up the wall, they also researched in printing the wall directly in the vertical position.

The tree-shaped post is partly 3D printed and partly poured concrete. A 3D-printed mold is created for pouring concrete for the bigger posts. Given the complexity of the structure and diversity of scale, different types of 3D print and fabrication techniques are used at making different parts of the structure.

Demonstrator Pavilion (2015)

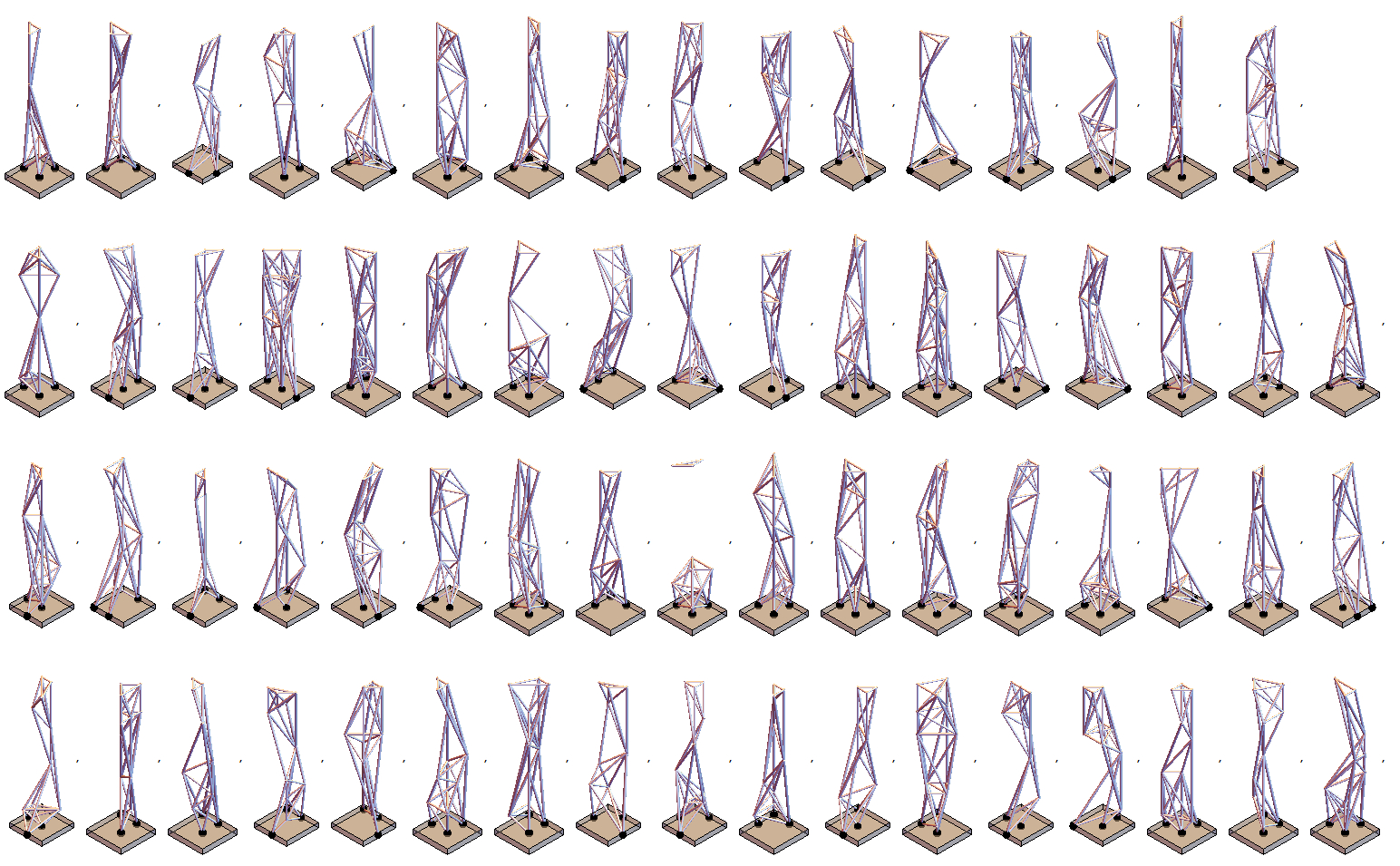

A genetic algorithm is created to study the relationship between mass, load and numbers of bar. The objective is to find a load-resisting truss with less material and number of bars. A 3D clay mold is printed for pouring concrete and after the concrete set, the clay is washed away and a smooth continuous concrete structure is fabricated.

See the XTreeE’s working process in the video below:

All images courtesy of XTreeE and Nikolaz Lecoq

> via VINCI Construction/XTreeE