Submitted by WA Contents

University of Michigan researchers create ultra-lightweight, freeform and waste-free concrete

United States Architecture News - Mar 29, 2023 - 14:08 4170 views

Researchers at the University of Michigan have created a 3D printed shell wall that can be used as "ultra-lightweight and freeform reinforced concrete" in concrete constructions.

The innovation of the freeform material, led by Professor Dr. Mania Aghaei Meibodi, Director of the DART Laboratory at the University of Michigan with two researchers Alireza Bayramvand and Yuxin Lin at the DART Laboratory, is claimed to be a "waste-free" concrete shell.

According to the researchers, the Shell Wall proposes "an efficient use of material by placing it precisely where it's needed for structural purposes."

To create this material, the team devised "a computational model that synergizes non-planar and variable material deposition based on the shape and geometric features of the topology-optimized parts."

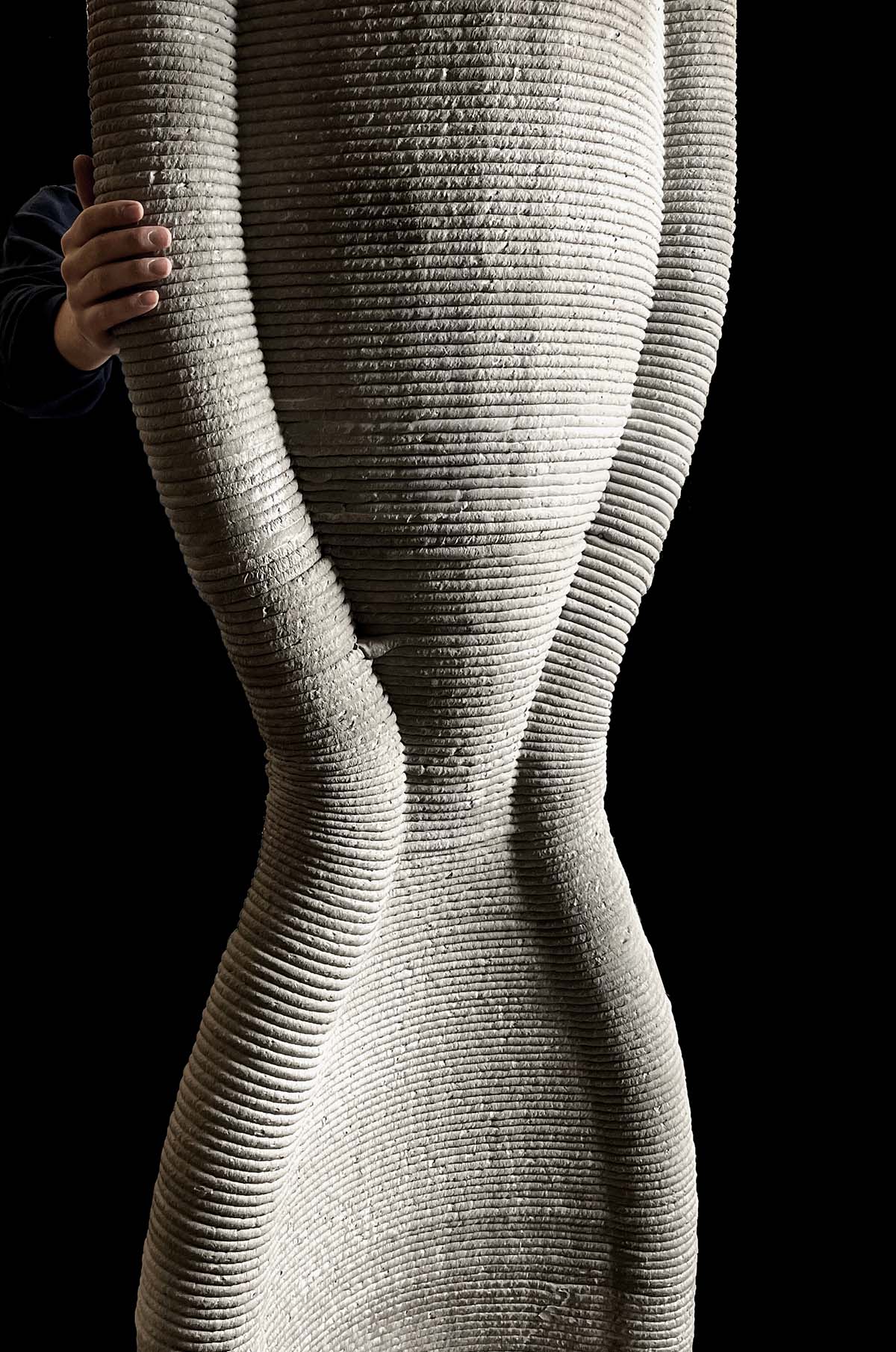

The Shell Wall, shown from front and back views, highlights the material reduction achieved through a thin membrane between structural ribs in a tall, doubly curved wall. Image courtesy of DART Laboratory

"One of the advanced features of that model is the ability to regenerate forms to closely match the initial optimization while taking into account any fabrication and material constraints," the team explained.

"The model automatically generates data for 3D printing, non-planar toolpaths, and variable material extrusion rates."

"Shell Wall demonstrator is the first lightweight, structurally reinforced freeform concrete wall ever 3D printed," the team added.

This innovative Shell Wall system is based on a geometry optimized to support its load case, with material distributed in a hierarchical grid of curved ribs ranging in diameter from 65 to 150 millimeters.

The team stated that "the non-load-bearing areas between these ribs are just 6.5 to 8 centimeters deep, enabling the sandwiching of insulation between two concrete shells that are only 2.5 millimeters thick."

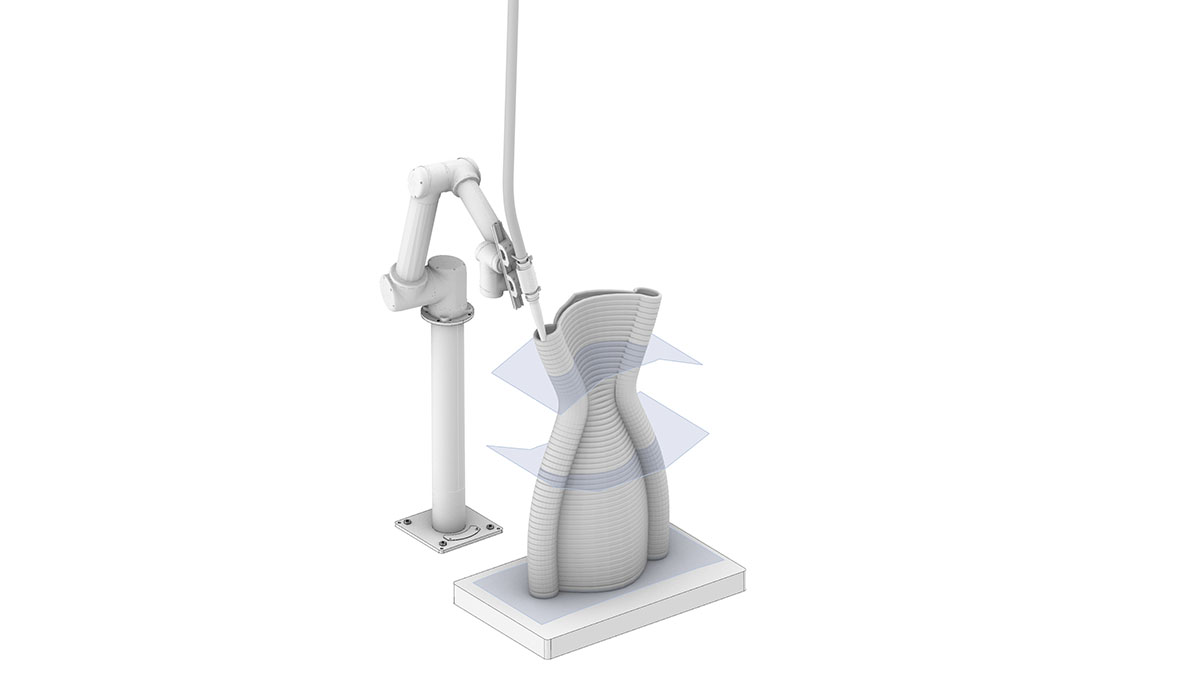

Shell Wall, perspective view showing the curved thin membrane between the structural ribs. Image courtesy of DART Laboratory

Ultra-lightweight and freeform Shell Wall

The fields of concrete between the ribs are domed to increase stability and minimize material usage.

Compared to a conventional solid concrete wall of equivalent size, the Shell Wall weighs only 160 kilograms, which provides a 72 per cent reduction in weight.

Through this innovative 3D printing method, the wall allows for "waste-free concrete construction and efficient use of material by placing it precisely where it's needed for structural purposes."

The team also added that "the 3D printing method also facilitates the practical implementation of 3D concrete printing by using commonly available concrete rather than relying on highly specialized mixes."

Shell Wall details. Showing the high-resolution layer deposition achieved using the developed technology. Image courtesy of DART Laboratory

"Shell Wall demonstrator uses a significantly smaller amount of concrete and rebar than the much larger quantities that would typically be required for a wall of the same dimensions."

Shell Wall. Showing the nonplanar layer deposition and the elegant transition from Membrane to Structured Ribs with Rebar Reinforcement. Image courtesy of DART Laboratory

Image courtesy of DART Laboratory

Image courtesy of DART Laboratory

Video courtesy of University of Michigan

Additionally, DART developed a lightweight and affordable 3D concrete printing system for Shell Wall to increase accessibility.

Similarly, last year MIT developed a method for 3D printed materials to detect how they are moving and interacting with the environment, and MIT's other research group created a new composite material that is tough as bone and hard as aluminum.

Moreover, chemical engineers at MIT created a new material "that is stronger than steel and as light as plastic" by using a novel polymerization process.

Top image: The Shell Wall, shown from front and back views, highlights the material reduction achieved through a thin membrane between structural ribs in a tall, doubly curved wall. Image courtesy of DART Laboratory.

> via DART Laboratory & University of Michigan

3D printed 3D printing concrete material University of Michigan waste-free concrete