Submitted by WA Contents

Gramazio Kohler Research used 30,000 soft clay bricks to install undulating clay rotunda in Bern

Switzerland Architecture News - Jul 14, 2021 - 16:23 5296 views

Zürich-based research and design studio Gramazio Kohler Research has used over 30,000 soft clay bricks to install this undulating rotunda within the SE MusicLab, a high-fidelity music auditorium built inside the newly refurbished Gurten Brewery in Bern, Switzerland.

Called Clay Rotunda, the installation was built over a period of 50 days as a free-standing earth-based cylindrical structure constituting the outer, soundproof shell.

The structure was designed by using clay, a sustainable zero-waste building material, with advanced computational design techniques. Clay Rotunda has a diameter of almost 11 meters, and the structure reaches a height of 5 meters with just 15 cm of unreinforced clay.

The team used a mobile robotic system to complete the structure in-situ. The clay Rotunda has an extreme slenderness which is made possible by its undulated design. Its curving layout also allows to increase the footprint and stabilize the structure in order to prevent buckling effects.

The team used a computational model that controls the geometry of this thin shell. Its shell was designed by taking into account the structural models of the engineers, the material properties of the clay as well as the sequencing of the building process.

Gramazio Kohler Research said that "In fact, the limited reach of the robotic arm and the shrinking of the material while drying demanded the implementation of complex strategies for the horizontal and vertical segmentation of the structure into matching trapezoids."

The team also noted that "the computational model also allowed computing the building sequence within each segment as well as the position of each one of the 30’000 clay cylinders."

"The particular orientation in which the robotic arm pressed them onto the structure was particularly important to ensure proper bonding between the different segments."

The model was designed by using all the fabrication data and technology needed to run the robotic process that allows the realization of bespoke structures of unmatched geometry complexity.

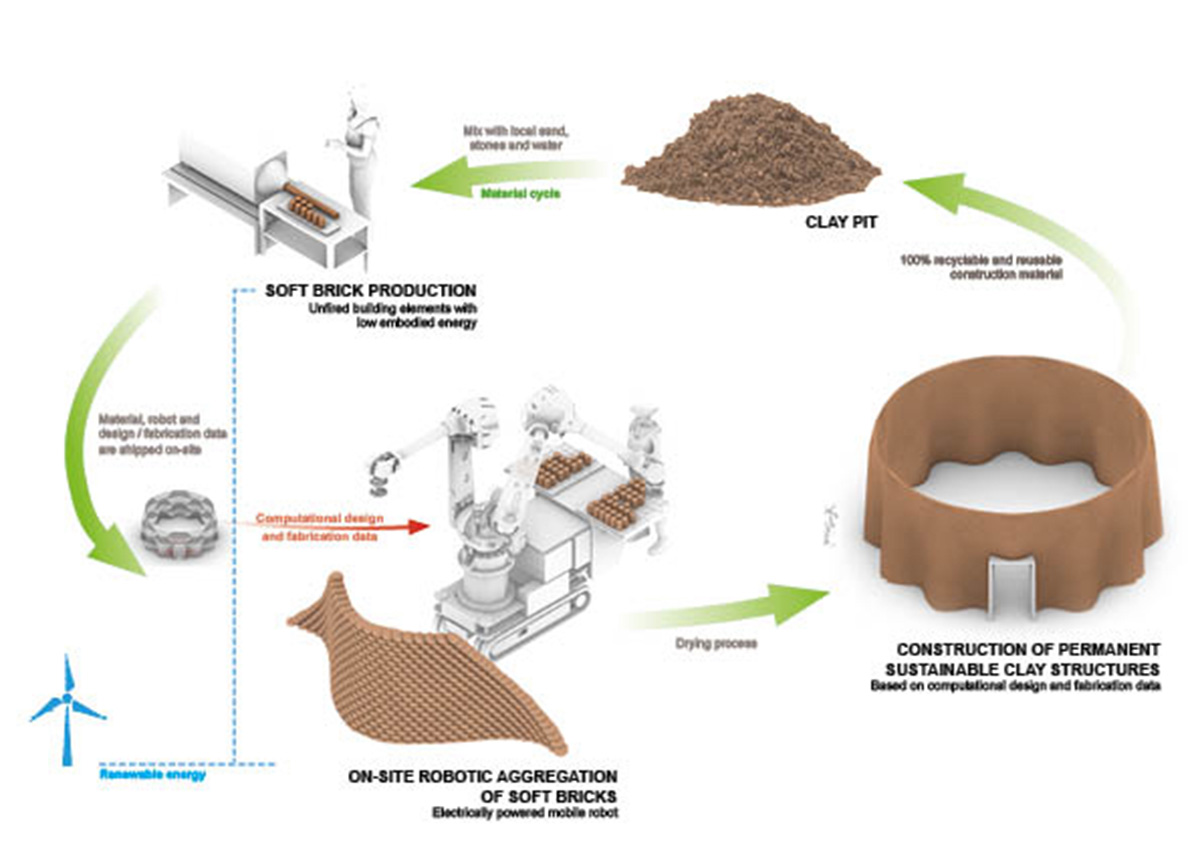

For the performance of the structure, the optimisation of the material system was a key factor in design. For this, the architects used different compositions of clay, sand, small stones and water - all of them have been tested with the aim of finding the best balance between the malleability needed by the fabrication process. As they noted, the highest compressive strength, and the minimal material shrinkage.

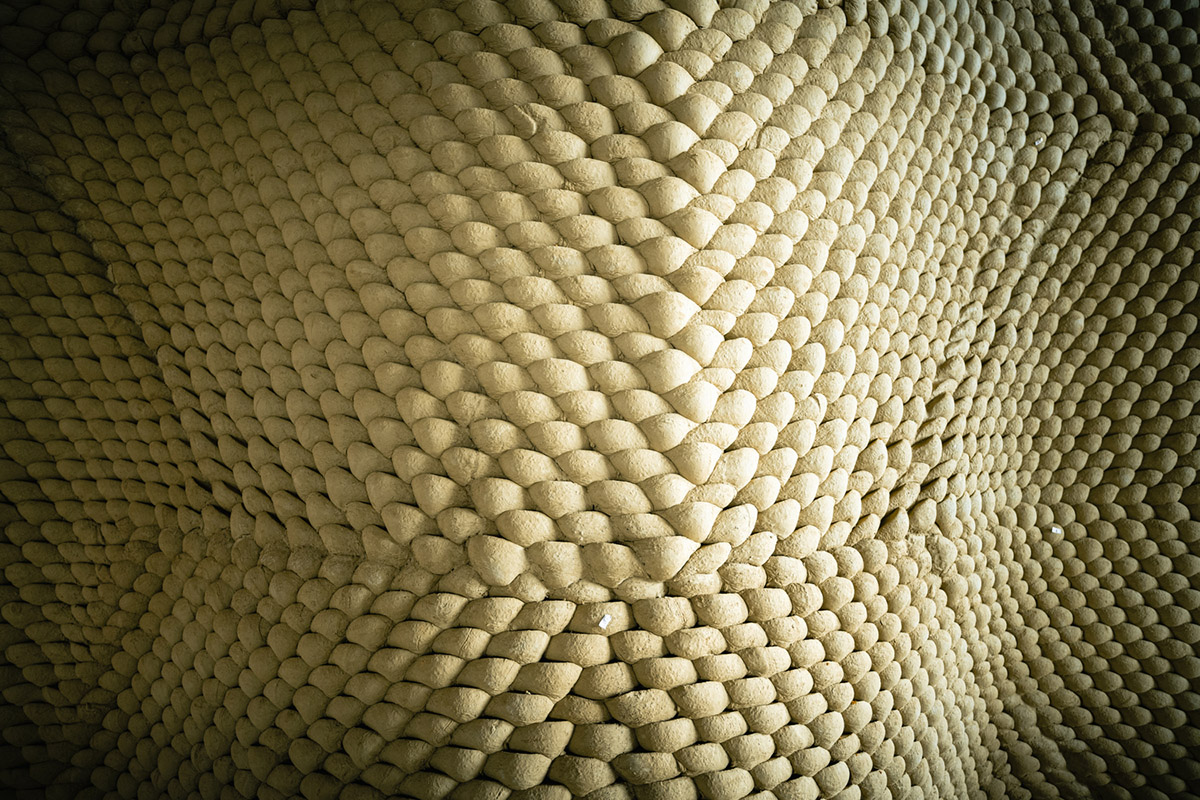

The developed clay mix is extruded into so-called soft bricks, cylinders with a diameter of 9 cm and a height of 15 cm, which are grabbed by the robotic arm from a picking station, precisely oriented, and sequentially pressed into their final position.

"The compression of about 60 per cent of the original height assures a strong and interlocking aggregation, leading to a soft bond that expresses both the plasticity of the material and the dynamic forces of the fabrication process," the team added.

The studio's custom robot - the in-situ fabricator - was moved for every single segment in order to address the full scale of the structure.

This relocation of the robot as well as the deformation of the fresh material caused by its shrinkage required a regular acquisition of the as-built geometry through 3D scanning. The unavoidable cracks that resulted from the drying process were actively monitored and regularly filled with the same clay mix.

Sustainability is the key design component in the overall process. As the architects emphasized, the Clay Rotunda also addresses the urgent need of reducing material consumption as well as revert to emission-free materials for the fabrication of our built environment.

The robotic clay aggregation process combines the traditional knowledge of clay constructions with contemporary digital design and fabrication processes. The increased degree of control on both material and process allows building complex structures that go beyond what has traditionally been possible.

As the studio noted, clay material has excellent properties since it regulates interior climate of buildings, thus reduces the need for mechanical ventilation and creates comfort for all inhabitants.

Finally, earthen constructions are entirely waste-free, since the used clay mix can be ground and fully reused. What is taken from nature can be returned entirely to nature?

All images courtesy of Gramazio Kohler Research, ETH Zurich

> via Gramazio Kohler Research