Submitted by WA Contents

Imperial College London and Empa researchers create bee-inspired flying 3D-printing drones

United Kingdom Architecture News - Sep 23, 2022 - 16:44 3249 views

Researchers from Imperial College London and the Swiss Federal Laboratories of Materials Science and Technology (Empa) have developed autonomous 3D printing drones working like bees to build and repair structures while flying.

Announced by Imperial College London on 21 September, the new technology has been tested in the lab and this technology could pave the ways for manufacturing and building industry in "difficult-to-access or dangerous locations".

Especially, 3D printing drones can fly over tall buildings or can support post-disaster relief construction, according to the researchers.

"3D printing is gaining momentum in the construction industry," stated in a press release by Imperial College London. "Both on-site and in the factory, static and mobile robots print materials for use in construction projects, such as steel and concrete structures."

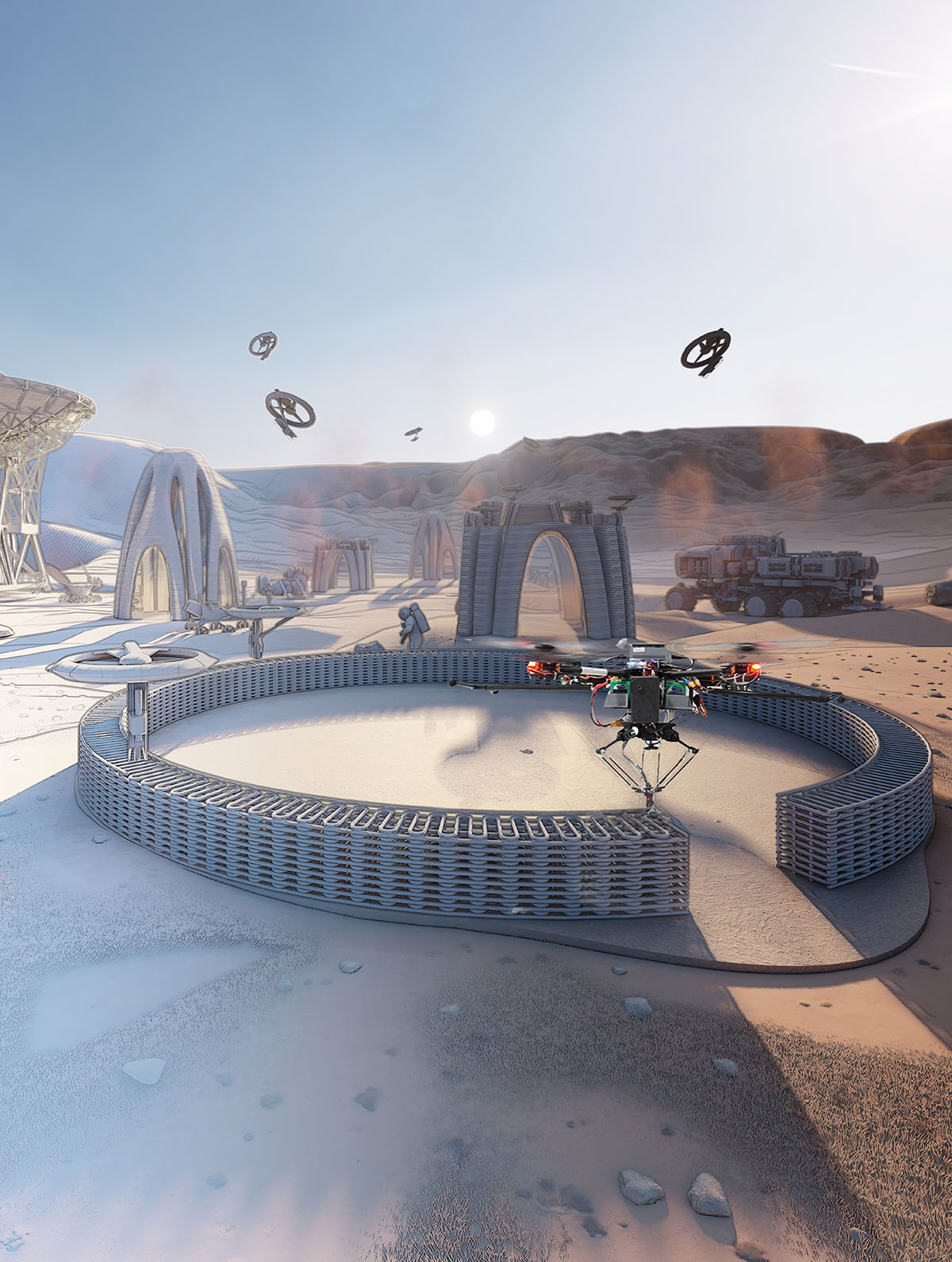

The conceptual representation of Aerial AM in hard-to-reach natural environments. Architectural design: Robert Stuart-Smith, Autonomous Manufacturing Lab, University of Pennsylvania & University College London. Image credit: Yusuf Furkan KAYA, Aerial Robotics Laboratory, Imperial College London and Materials and Technology Centre of Robotics, Swiss Federal Laboratories of Material Science and Technology (Empa)

Imperial College London and Empa describe the technology as "a new approach to 3D printing" which uses flying robots, known as drones.

Based on collective building methods, the methodology of 3D printing drones is inspired by natural builders like "bees" and "wasps who work together to create large, intricate structures."

"We’ve proved that drones can work autonomously and in tandem to construct and repair buildings, at least in the lab," said Professor Mirko Kovac, Department of Aeronautics & Empa.

The drones in the fleet, known collectively as Aerial Additive Manufacturing (Aerial-AM), and "can work co-operatively from a single blueprint, adapting their techniques as they go."

Although they are acting as fully autonomous while flying, there still needs a human controller to monitor the 3D printing drones and their progress and intervenes "if necessary, based on the information provided by the drones."

In order to fly bee-inspired 3D printing drones, their system uses BuilDrones and ScanDrones, which deposit materials and make quality control during flight. Thanks to these features, ScanDrones "can continually measure the BuilDrones’ output and inform their next manufacturing steps."

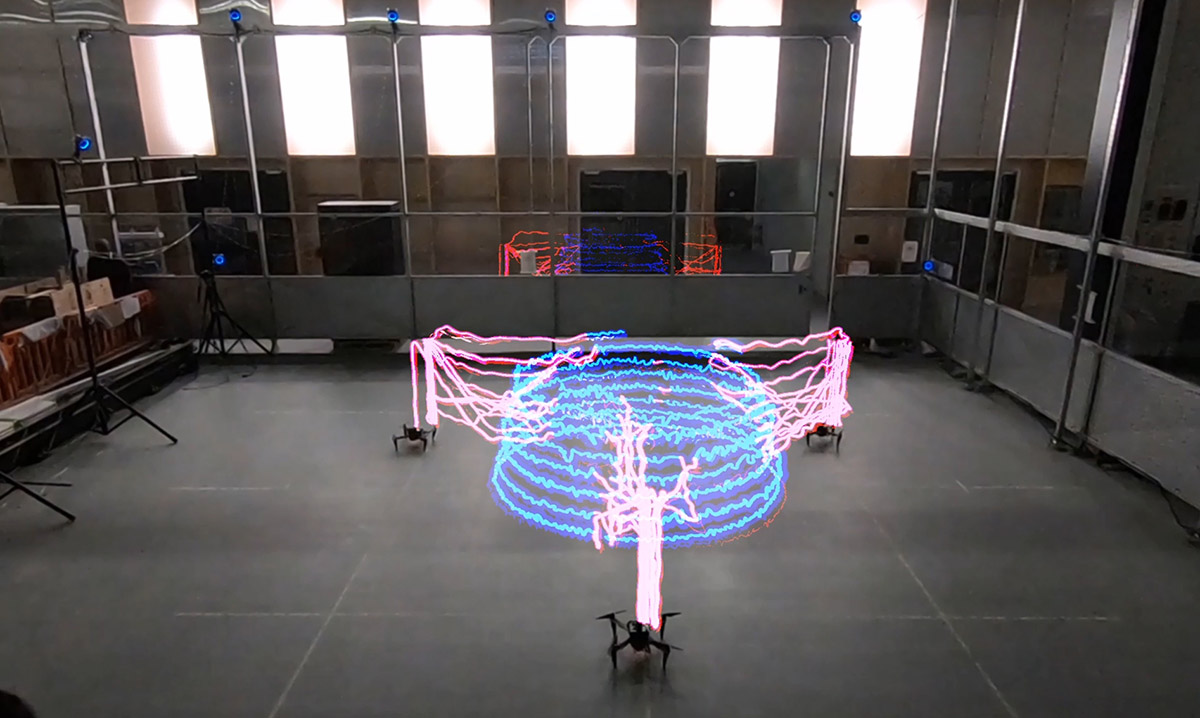

Aerial AM Cementitious 3d print using a custom buildDrone with a delta-arm manipulator. Image credit: Videos taken at the Imperial College London Aerial Robotics Laboratory by all partners (Imperial College London, University College London, University of Bath)

"3D printing drones could help reduce the costs and risks of construction"

"To Aerial-AM uses both a 3D printing and path-planning framework to help the drones adapt to variations in geometry of the structure as a build progresses," stated in the press release.

Professor Mirko Kovac also added that, "Our fleet of drones could help reduce the costs and risks of construction in the future, compared to traditional manual methods."

The researchers have tested the concept by using four bespoke cement-like mixtures for the drones to build with.

Aerial AM foam 3d print. Sarah Lever photography. Autonomous Manufacturing Lab, University College London

"Throughout the build, the drones assessed the printed geometry in real time and adapted their behaviour to ensure they met the build specifications, with manufacturing accuracy of five millimetres," added the researchers.

"The proof-of-concept prints included a 2.05-metre high cylinder (72 layers) with a polyurethane-based foam material, and an 18-centimetre high cylinder (28 layers) with a custom-designed structural cementitious material," explained in the press release.

“Aerial Additive Manufacturing with Multiple Autonomous Robots” by Zhang et al., published 21 September 2022 in Nature, the leading international weekly science journal.

Aerial AM Cementitious 3d print using a custom buildDrone with a delta-arm manipulator. Image credit: Videos taken at the Imperial College London Aerial Robotics Laboratory by all partners (Imperial College London, University College London, University of Bath)

Robert Stuart-Smith, Stefan Leutenegger, Vijay Pawar, Richard Ball, Chris Williams and Paul Shepherd, and their research teams at UCL, University of Bath, University of Pennsylvania, Queen Mary University of London, and Technical University of Munich (TUM) are co-investigators of the project.

Timelapse light trace demonstrating multi-agent coordination of Aerial AM robot team. Image by Autonomous Manufacturing Lab, University College London

Multi-Agent Aerial AM Simulations. Image by Autonomous Manufacturing lab, Penn

The project was launched by Assistant Professor Stuart-Smith at UCL and University of Pennsylvania and Professor Kovac at Imperial and Empa after a pilot research collaboration and award for a demonstration on pipeline repair.

Top image: The conceptual representation of Aerial AM in extra-terrestrial missions and extreme polar regions. Architectural design: Robert Stuart-Smith, Autonomous Manufacturing Lab, University of Pennsylvania & University College London. Image credit: Yusuf Furkan KAYA, Aerial Robotics Laboratory, Imperial College London and Materials and Technology Centre of Robotics, Swiss Federal Laboratories of Material Science and Technology (Empa).

> via Imperial College London

3D printing Aerial Additive Manufacturing construction drones