Submitted by WA Contents

The curved Urbach Tower was built from self-shaping wood on the Rems Valley

Germany Architecture News - May 21, 2019 - 05:04 19502 views

A curved wooden tower is a landmark rising on the Rems Valley in Germany. The 14-metre tower's unique form and structure highlight the architectural and structural application of curved timber plates produced using an innovative large-scale self-shaping manufacturing method.

Designed by Institute for Computational Design and Construction, University of Stuttgart (ICD) and Institute of Building Structures and Structural Design, University of Stuttgart (ITKE), the Urbach Tower, featuring a striking timber structure, was built to serve as a landmark building for the Remstal Gartenschau 2019.

Pushing the boundaries of the technology, by using this pioneering development, the Urbach Tower constitutes a paradigm shift in timber manufacturing from elaborate and energy-intensive mechanical forming processes that require heavy machinery to a process where the material shapes entirely by itself.

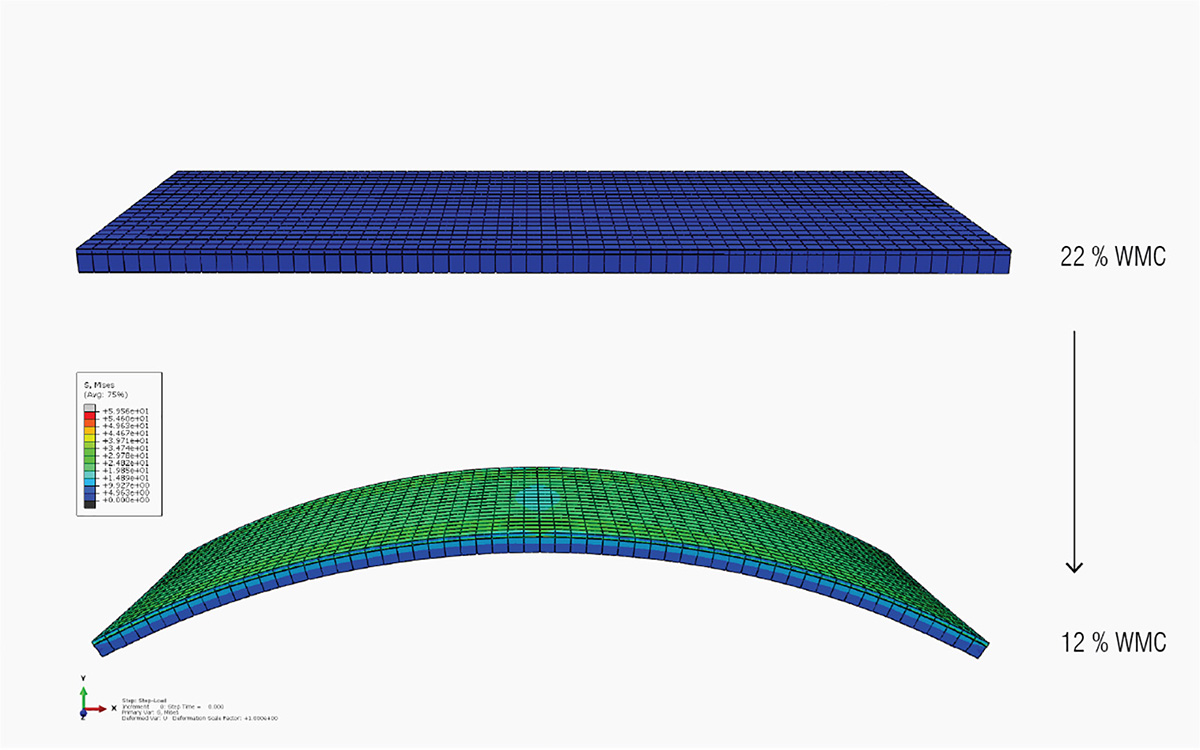

This shape change is only driven by the wood’s characteristic shrinking during a decrease of moisture content. Components for the 14-meter-tall tower are designed and manufactured in a flat state and transform autonomously into the final predicted curved shapes during the industry-standard technical drying.

"The technology of self-shaping manufacturing for solid timber boards and the rapid adaptability of the process to different curvatures open up new and unexpected architectural possibilities for thin shell wood structures, using a sustainable, renewable, and locally sourced building material," said ITKE team.

"In timber construction, moisture typically causes problems with cracking and deformation; hence, moisture changes and stress development must be carefully controlled."

"In contrast, in this project wood is programed and arranged in a way to utilize this powerful, naturally occurring deformation to trigger a designed self-shaping behavior. In the same way that machines can be programmed to perform different movements, wood parts can be programmed to transform into predetermined shapes when dried," they added.

Self-shaping manufacturing at building scale

The curved Cross Laminated Timber (CLT) components for the tower’s structure are designed and produced as flat panels that deform autonomously into predicted curved shapes when dried. The 5.0 m x 1.2 m spruce wood bilayers parts are manufactured with a high wood moisture content and specific layups and dried in an industry standard technical drying process.

When removed from the drying chamber the parts are precisely curved. The parts are overlapped and laminated together to lock the geometry in place, forming larger curved CLT components with form stable geometry.

"Material specific computational mechanics models have been developed to both design, predict, and optimize the material arrangement required to produce different curvature types and radius," explained the team.

"The Urbach Tower is the very first implementation of this technology on building-scale, load-bearing timber parts."

Thin-shel high-performance timber structure

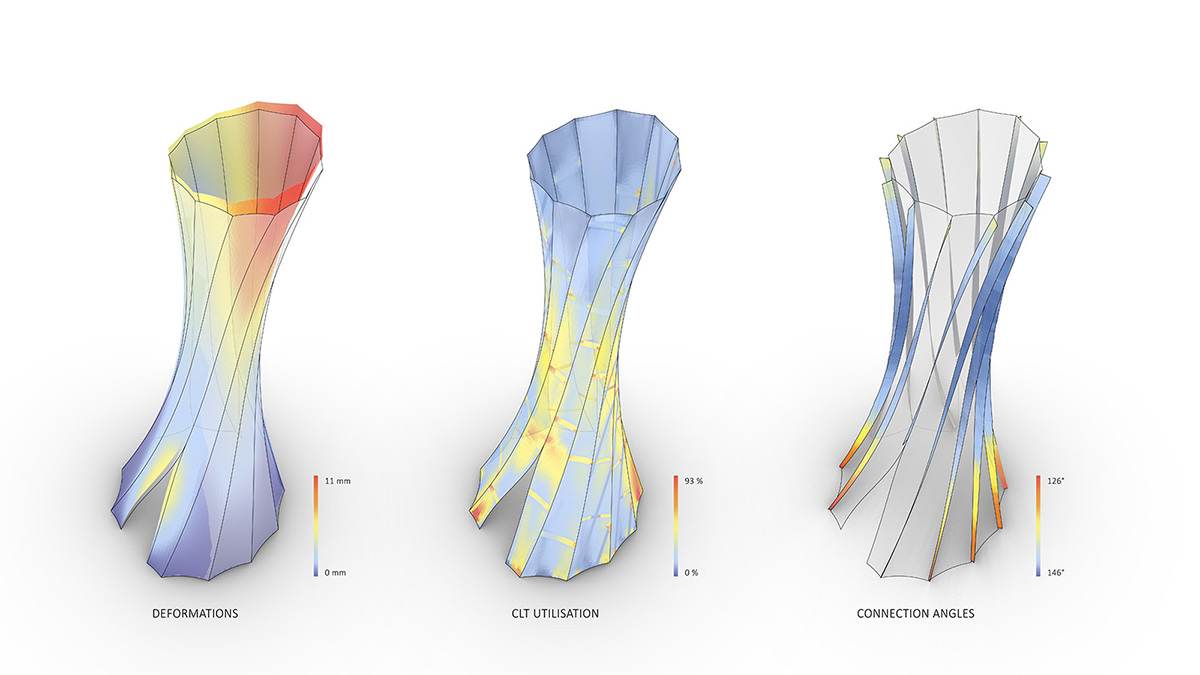

The Urbach Tower consists of 12 curved components made from cross-laminated timber. The tower’s load-bearing structure exhibits a thickness of 90mm while cantilevering over 14 meters resulting in a span to thickness ration of approximately 160/1.

The inherent curvature enables a highly slender and lightweight tower structure of only 38 kg per square meter surface area. In the assembled state, the tower acts as a surface-active structure through its expressive curved geometry.

The lightweight building elements are connected by crossing screws, the arrangement and specific angle of which is optimised throughout the structure in relation to their utilization while preserving a continuous connection along the seam for homogeneous load transfers.

The prefabricated assembly groups of the tower, each consisting of three curved components, were assembled in a single working day by a team of four craftsmen without the requirement of extensive scaffolding or formwork, and topped-off by a transparent roof.

The structure showcases the possibilities for efficient, economical, ecological and expressive wood architecture that arises at the intersection of master craft, digital innovation and scientific research.

The Urbach Tower is one of 16 stations designed by some of the most renowned German architects for the Remstal Gartenschau 2019. The stations are small, permanent buildings that evoke the traditional white chapels distributed in the fields and vineyards along the scenic Rems Valley.

Located on a prominent hillside in the center of the valley, the 14 m tall tower is a striking landmark that visually connects several stations. It provides a place of shelter, internal reflection and outward view by revealing stunning vistas and framing the landscape.

"The concave curvature of the structure on the outside results in sharp lines and crisp surfaces, which is further accentuated by direct day light and whitening of the larch cladding over time," added the team.

"In contrast, on the interior the convex curvature creates an unexpected visual and tactile material experience, with the timber structure appearing to be almost soft and textile-like, highlighted by the light washing the gently undulating surfaces. Opposite the entrance, the thin wood envelope opens like curtain, putting the Rems Valley on center stage."

Process Photographs. Image © ICD/ITKE, University of Stuttgart and Empa, Dübendorf, Switzerland

Process Photographs. Image © ICD/ITKE, University of Stuttgart and Empa, Dübendorf, Switzerland

Project facts

ICD – Institute for Computational Design and Construction, University of Stuttgart

Prof. Achim Menges, Dylan Wood

Architectural Design: Self-forming Curved Wooden Components Research and Development

ITKE – Institute of Building Structures and Structural Design, University of Stuttgart

Prof. Jan Knippers, Lotte Aldinger, Simon Bechert

Structural Design and Engineering

Scientific collaboration:

Laboratory of Cellulose and Wood Materials, Empa (Swiss Federal Laboratories for Materials Science and Technology), Switzerland & Wood Materials Science, ETH Zurich (Swiss Federal Institute of Technology Zurich), Switzerland.

Dr. Markus Rüggeberg, Philippe Grönquist, Prof. Ingo Burgert

Self-forming Curved Wooden Components Research and Development (PI).

Industry collaboration:

Blumer-Lehmann AG, Gossau, Switzerland

Katharina Lehmann, David Riggenbach

Self-forming Curved Wood Components Research and Development,

Wood Manufacturing and Construction

Project support:

Gemeinde Urbach

Remstal Gartenschau 2019 GmbH

University of Stuttgart

German Federal Environmental Foundation

Design, Fabrication and Engineering Methods for the application of curved wood elements in high-performance, resource-efficient wood construction: Project Tower Urbach, Remstal Gartenschau 2019.

Innosuisse – Swiss Innovation Agency

Smart, Innovative Manufacturing of Curved Wooden Components for Architecture with Complex Geometry

All images © ICD/ITKE, University of Stuttgart unless otherwise stated.