Submitted by WA Contents

MIT develops mass manufacture of disposable face shields for health care professionals

United States Architecture News - Apr 17, 2020 - 13:33 10703 views

The Massachusetts Institute of Technology (MIT) has started to produce mass manufacture of disposable face shields for health care professionals in response to Covid-19.

A team from MIT has released design for disposable face shields that can be mass produced quickly to address hospitals’ needs nationwide. MIT has also opened a request form to deliver the products to verified health care providers, EMS, urgent care clinics, or other entities.

A manufacturer is expected to call the MIT to discuss availability, price, and delivery timeframes.

Video by MIT Project Manus

Graduate student Zach Fredin operates the Zund large-format cutter in MIT’s Center for Bit and Atoms. The machine was used to make prototypes of the face shield. Image © Center for Bits and Atoms

"The shortage of personal protective equipment (PPE) available to health care professionals has become increasingly problematic as Covid-19 cases continue to surge," said MIT in its press statement.

"The sheer volume of PPE needed to keep doctors, nurses, and their patients safe in this crisis is daunting — for example, tens of millions of disposable face shields will be needed nationwide each month."

"This week, a team from MIT launched mass manufacturing of a new technique to meet the high demand for disposable face shields."

The team uses single piece face shield that is made of by using a process known as die cutting. As the MIT explains it technically, machines cuts the design from thousands of flat sheets per hour.

MIT plans on purchasing the first 40,000 face shields to donate to local Boston-area hospitals this week and the fabrication facilities involved in its production will donate 60,000. Image © Project Manus

"Once boxes of these flat sheets arrive at hospitals, health care professionals can quickly fold them into three-dimensional face shields before adjusting for their faces."

"These face shields have to be made rapidly and at low cost because they need to be disposable," explained Martin Culpepper, professor of mechanical engineering, director of Project Manus, and a member of MIT’s governance team on manufacturing opportunities for Covid-19.

"Our technique combines low-cost materials with a high-rate manufacturing that has the potential of meeting the need for face shields nationwide."

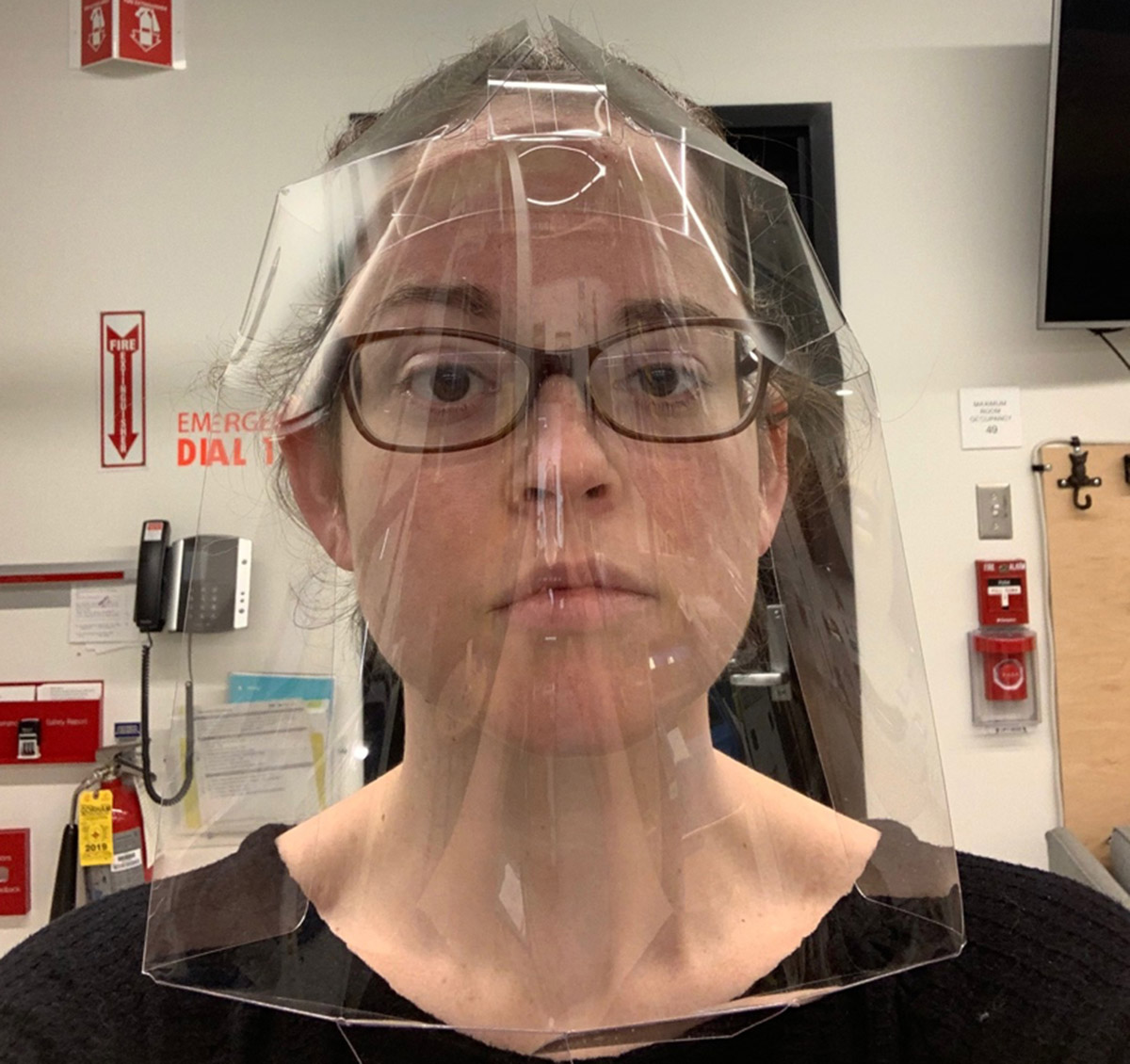

The face shield provides healthcare workers with full coverage around the forehead, neck, and sides of the face. Image © Project Manus

The face shield provides healthcare workers with full coverage around the forehead, neck, and sides of the face. Image © Project Manus

MIT and Culpepper's team spearheaded the development of the technique with other partners and industry

MIT stated that "Culpepper and his team at Project Manus spearheaded the development of the technique in collaboration with a number of partners from MIT, local-area hospitals, and industry."

The team has also been working closely with the MIT Medical Outreach team and the Crisis Management Unit established by Vice President for Research Maria Zuber and directed by Elazer R. Edelman, the Edward J. Poitras Professor in Medical Engineering and Science at MIT.

"When you’re thinking of materials, you have to keep supply chains in mind. You can’t choose a material that could evaporate from the supply chain. That is a challenging problem in this crisis," explained Culpepper.

"After testing a few materials that cracked and broke when bent, the team chose polycarbonate and polyethylene terephthalate glycol – known more commonly as PETG – as the shield’s material."

In addition to making more prototypes at the Project Manus Metropolis Makerspace using a laser cutter, Culpepper worked with Professor Neil Gershenfeld and his team at MIT’s Center for Bits and Atoms (CBA) on rapid-prototyping designs for testing using a Zund large-format cutter.

Elazer Edelman, the Edward J. Poitras Professor in Medical Engineering and Science at MIT, wears a face shield developed through a collaborative effort involving groups across MIT while holding an electronic, Bluetooth-enabled stethoscope. In this photo, Edelman is wearing the shield in the snapped up position healthcare workers also have the option to use. Image © Elazer Edelman

New face shields go to testing phase at local hospitals

With a number of working prototypes built, Culpepper and his team now moved to the testing phase after consultation with, and practical feedback from, Professor Elazer Edelman, who is also a physician and MIT’s Office of the Vice President for Research.

"The single greatest insecurity of a health care provider is the thought that we will become infected and in doing so be unable to perform our duties or infect others," added Edelman.

Edelman demonstrated how to store, assemble, and use the face shields for nurses and physicians at a number of area hospitals. Participants were then asked to use them in real-life situations and provide feedback using a one-page survey.

"The feedback was overwhelmingly positive — participants found that in addition to being easy to assemble and use, the MIT-designed shields provided good protection against coming in contact with virus particles through splashes or aerosolized particles," added MIT.

Armed with this feedback, Culpepper’s team made a few minor adjustments to the design to maximize coverage around the sides and neck of users. With the design finalized, the project has this week shifted to high-rate mass manufacturing.

MIT plans produce approximately 50,000 shields per day in a few weeks and they added that they will continue to meet the rising demands and increase the rate of manufacturing further with the ability to fabricate in more than 80 facilities nationwide.

"This process has been designed in such a way that there is the potential to ramp up to millions of face shields produced per day," explained Culpepper. "This could very quickly become a nationwide solution for face shield shortages."

According to the statement, MIT plans on purchasing the first 40,000 face shields to donate to local Boston-area hospitals this week and the fabrication facilities will donate 60,000.

"Having an adequate and perhaps even endless supply of PPE is absolutely critical to ensuring the safety of the entire population, especially those who care for Covid-19 patients," added Edelman.

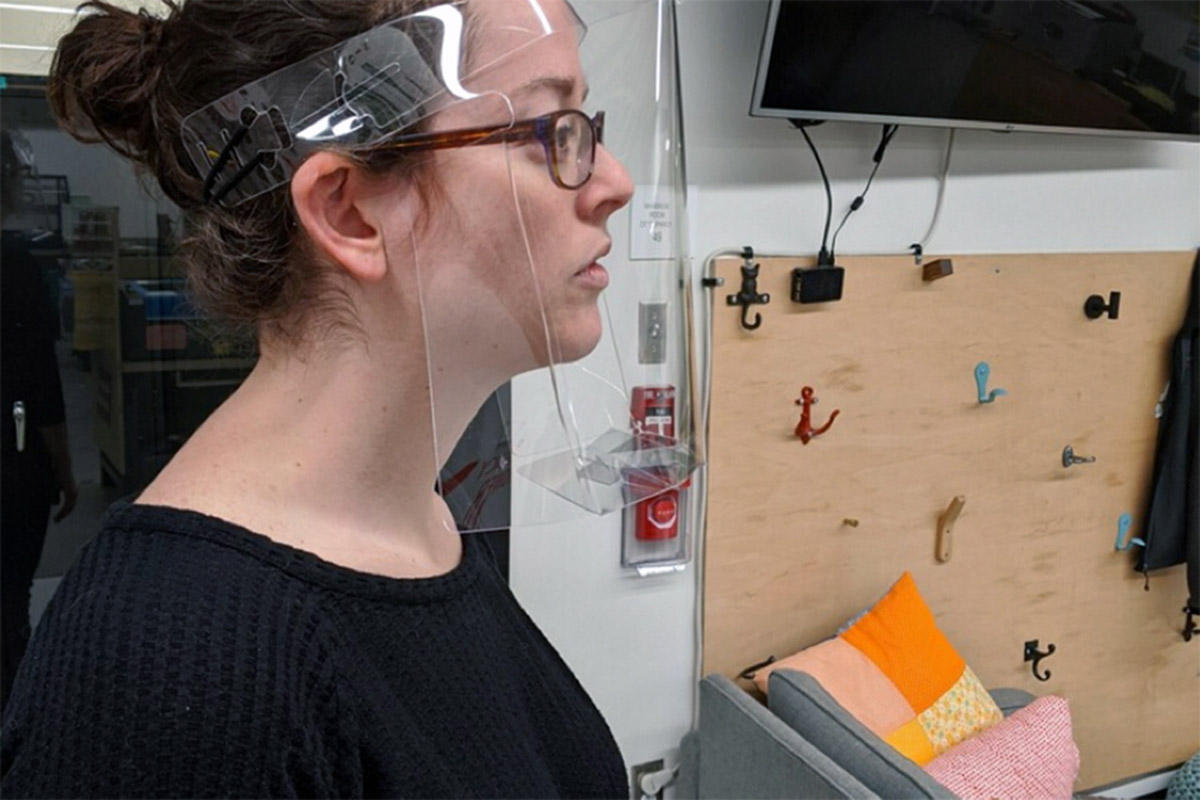

Robyn Goodner, who serves as a Maker Technical Specialist for Project Manus, models the face shield design in the Metropolis Makerspace. Image © Project Manus

Throughout the process, Culpepper’s team collaborated with a number of colleagues and departments across MIT.

The collaborative effort includes MIT’s Office of the Vice President for Research, Professor Elazer Edelman, Tolga Durak, managing director of the MIT Environment, Health and Safety Office, the Center for Bits and Atoms, MIT Procurement Operations, MIT’s Office of the General Counsel, MIT’s Department of Mechanical Engineering, the Martin Trust Center for MIT Entrepreneurship, and colleagues from MIT Lincoln Laboratory, who helped source material to build the face shields and supported design iterations. They also received advice from MIT colleagues working with the Massachusetts Technology Collaborative, which is helping organize manufacturers for Covid-19 response.

"This project was a great example of collaboration across MIT and the employment of mind-heart-hand. When we reached out to others, they dropped everything to put their minds and hands to work helping us make this happen quickly," said Culpepper.

"It is also a great example for others to look to safely and rapidly innovate PPE for Covid-19."

> via MIT