Submitted by WA Contents

AA Students’ fabrication jagged-red brick wall interprets new innovative architectonic spaces

United Kingdom Architecture News - Jul 28, 2016 - 11:01 16408 views

'InFlux' is a new wall prototype produced by AA School of Architecture recent graduates and current tutors at the AA within the scope of Summer DLAB: ORANGE, which will be exhibited at London's Hooked Park between Monday 25 July – Friday 12 August 2016. Program directors of Summer DLAB are Elif Erdine and Alexandros Kallegias.

Summer DLAB experiments with the integration of algorithmic / generative design methodologies and large scale digital fabrication tools. Continuing its color based agenda, Summer DLAB immerses in ‘orange’ for its 2016 cycle, as a starting point to investigate principles of natural formation processes and interpret them as innovative architectonic spaces. These concepts are carefully interwoven with spatial, performance-based, and structural criteria in order to create full-scale working prototypes.

Image © Mathias Reisigl

The three-week long programme is formulated as a two-phase process. During the two-week initial phase, participants benefit from the unique atmosphere and facilities of AA’s London home. The second phase, lasting for a week, shifts to AA Hooke Park and revolves around the fabrication and assembly of a full-scale architectural intervention realized by the use of robotic fabrication techniques in AA’s Hooke Park premises.

Image © Mathias Reisigl

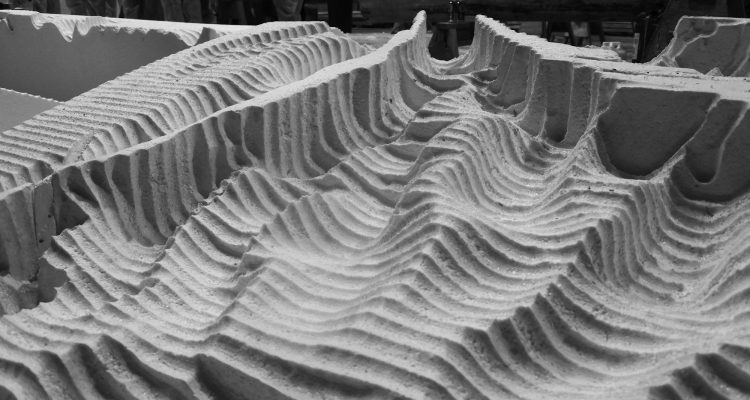

InFlux is the outcome of an exploration on the fabrication and assembly of double-curved complex geometries through the integration of generative design techniques and robotic milling strategies. The research initiated on the material behaviour of concrete in 2014 has been developed in the 2015 cycle by further investigations linking geometry, material, and structure.

Image © Mathias Reisigl

Realized as a wall with 2.2 meters height, 4 meters width, and a varying depth of 3 – 25 cm, InFlux has been developed, fabricated and assembled in 7 days.

Image courtesy of Architectural Association School of Architecture

Initial form-finding experiments on doubly-curved geometries have been combined with structural analysis tools in order to distribute openings and areas with different curvature values throughout the global form. Local manipulations have involved the implementation of the robot end-effector as a design tool that aided in the differentiation of surface textures.

Image courtesy of Architectural Association School of Architecture

The material behaviour of concrete has been analysed through various iterations as the surface area of the scaffolding have been increased. EPS foam-board has been used as the scaffolding material, machined with a drill cutter. The areas of contact between the scaffolding and concrete have been treated with a mold release agent.

Image courtesy of Architectural Association School of Architecture

AA London houses cutting-edge facilities for the fabrication of physical outputs through digital fabrication techniques or other forms including the use of plastics, wood, and metal. Digital Prototyping Lab (DPL) offers laser cutting, CNC milling, and 3d printing facilities. The facilities at AA Hooke Park allow for the fabrication of one-to-one scale prototypes with a 3-axis CNC router, various woodworking power tools, and robotic fabrication.

Image courtesy of Architectural Association School of Architecture

Top image © Mathias Reisigl