US$2Million Business Package Proposal for the BIOGAS NPK² Odorless Waste Recycling Facility consists of a Biogas Generator Waste Recycling Facility and an Industrial Production Facility.

The Biogas Generator Waste Recycling Facility is the only technology in the whole world eliminates the odor of biodegradable waste by recycling the waste in just 24 hours to produce odorless, organic Liquid Food Supplement (LFS) that can be sold and used as Plant Supplement/Fertilizer or Animal Food for livestock, poultry, aquaculture farms. The facility also produces methane gas for cooking and electricity. This technology was designed and created by a renowned Filipino Bio-Engineer and Ecological Solid Waste Management (ESWM) Consultant. Operational models have already been built locally, in Japan, Korea, Germany and US since 2014 for LGUs, households, schools, abattoirs, livestock farms, convents, poultry dressing plants including large-scale farm like of Monterey and poultry dressing plant for Vitarich. The Biogas Generator Waste Recycling Facility could also be designed to service local government units, townships, hospitals, markets, resorts and housing projects.

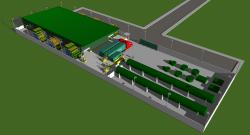

The Biogas Generator Waste Recycling Facility comes with a green and sustainable Industrial Production Facility designed by Architect Hermenegildo Mercado for the daily packing of the odorless, organic Liquid Food Supplement (LFS) by-product of the waste recycling facility. Each Industrial Production Facility can be customized in scale to match the different models of Biogas Generator Waste Recycling Facility needed.

INVESTMENT COST

BIOGAS NPK² ODORLESS WASTE MANAGEMENT SYSTEM ( business-level model)

In US Dollars : Two Million

(US$ 2,000,000.00) only, exclusive of VAT

The US$2Million Business Package Proposal for the BIOGAS NPK² Odorless Waste Management System includes two facilities that can be built in a 180 days and requires a lot area of 800 square meters as follows:

1. The Biogas Generator Waste Recycling Facility (in a 400 square meters lot area) that consists of a sealed Digester Fermentation Tank that recycles biodegradable waste into odorless organic Liquid Food Supplement (LFS) daily, a pre-mix lagoon, a Liquid Food Supplement lagoon, and an underground water tank with variations depending on biomass fuel type that will be fed into the Digester Fermentation Tank.

2. The green and sustainable Industrial Production Facility ( in a 400 square meters lot area) designed by Architect Hermenegildo Mercado for logistics, packing and storage of 1,700 drums of Liquid Food Supplement (LFS) with office/CCTV station, bedroom, toilet and bath, stacking rack systems, generator system, , built-in free electricity and cooking gas.

The US$2Million Business Package Proposal for the BIOGAS NPK² Odorless Waste Management System is a lucrative business proposal that can generate an income of US$280,000/month (US$3,369,000/year ) to US$1,404,000/month (US$16,848,000/year ) to US$2,808,000/month (US$33,696,000/year ) or more depending on the price and marketing strategy. This model recycles biodegradable waste in just 24 hours to produce 52,000 liters of odorless organic Liquid Food Supplement (LFS) and methane gas for cooking and electricity.

There are two types of Liquid Food Supplement (LFS) by-product as follows; Regular LFS that comes from pure animal waste and rich in organic nutrients

and Premium LFS that comes from animal waste mixed with vegetables, fruits and fish waste producing higher organic nutrients.

SAMPLE COMPUTATIONS for sale of Liquid Food Supplement (LFS) as animal food or plant supplement /fertilizer:

52,000 liters daily of Regular LFS @ US$0.18/liter = US$9,360/day or US$280,000/month or US$3,369,000/year

52,000 liters daily of Premium LFS @ US$0.90/liter = US$46,800/day or US$1,404,000/month or US$16,848,000/year

52,000 liters daily of Premium LFS @ US$1.80/liter = US$93,600/day or US$2,808,000/month or US$33,696,000/year

The odorless, organic Liquid Food Supplement (LFS) can be used as a cheap plant supplement or organic soil fertilizer for all plants, crops, ornamentals and fruit trees. A one-hectare rice farm will use 6 gallons of LFS for the seedlings as plant supplement in the preparation bed, 2 drums of LFS as soil fertilizer during soil cultivation, then 2 drums of LFS when the rice plant is knee-high until harvest. Second harvest will use 3 drums and lesser as soil becomes increasingly more fertile over time. This makes the soil so fertile that LFS will be no longer be needed after four years. Traditional fertilizers will cost much more per hectare of farmland. Liquid Food Supplement (LFS) has been used extensively since 2014 to the present in agricultural farms of Misamis Occidental and Isabela.

LIVELIHOOD PROGRAM FOR THE JOBLESS MARGINALIZED PEOPLE

Apart from using fruits and vegetables as biomass fuel mixed with animal waste, any variety of grass like Napier Grass can be mixed as well for the Digester Fermentation Tank. Poor, jobless and indigenous people can plant and harvest Napier Grass in idle government lands and organized as members of a Cooperative Livelihood Program under the Local Government Unit to earn income from the sale of LFS. Each member of the Cooperative will be registered as members in PAGIBIG to qualify and be eligible for its socialized housing loan program.

2023

FEATURES

1. Any plant, vegetable, fruit waste & animal waste any biodegradable waste can be used as feed for once a day breeding in a sealed Digester Fermentation Tank for recycling in just 24 hours only for a continuous production of as much as 52,000 liters of odorless, organic Liquid Food Supplement (LFS) daily or 390,000 gallons (7,000 drums) / month that could be sold to support a livelihood and income-generating program for local government and their poor , jobless constituents.

2. The Business Package Module is designed to be a Biogas Generator Waste Recycling Facility connectible in series. Additional tanks can be interconnected for future expansion in modules for bigger waste disposal and LFS output with a matching connectible Industrial Production Facility to increase production of Liquid Food Supplement (LFS) and methane gas for cooking.

3. Exclusive tank design can withstand high pressure of more than 50 psi with no danger of tank explosion, pollution while enabling maximum distant distribution.

4. The Biogas Generator Waste Recycling Facility is used by existing industry large-scale livestock farms (Monterey), chicken dressing plant (Vitarich) and a model has been built in US and Japan. Liquid Food Supplement (LFS) is rich in Vitamin B12, amino acids and is an ideal animal food for livestock , poultry, aquaculture (prawns, crabs, and fish) farms. Chicks bred and fed with LFS for poultry farms and cockfighting have been proven to be stronger, healthier and more resistant to disease. A recent grower using LFS food supplement had zero mortality rate for 20,000 chickens he raised.

for funding