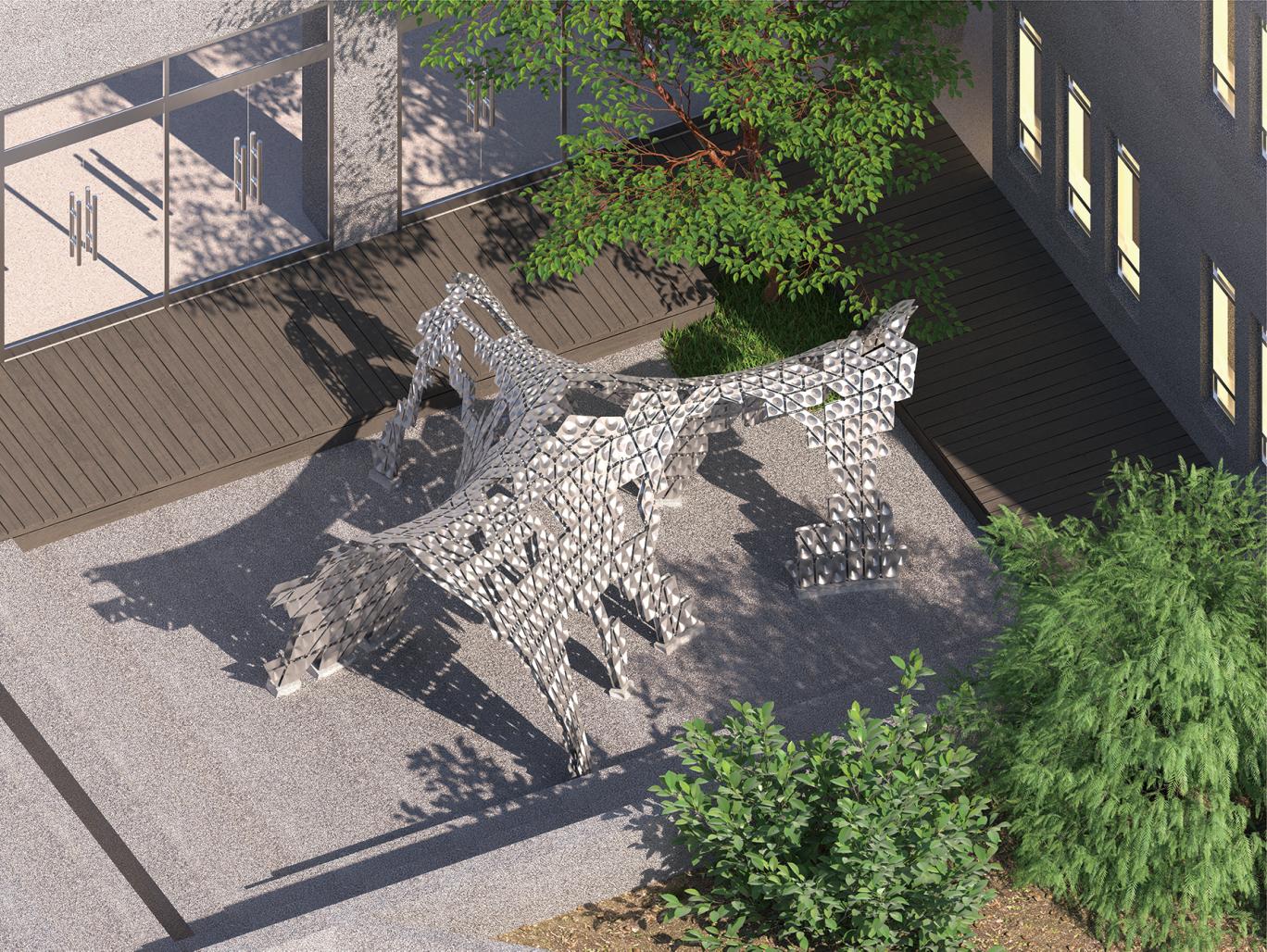

Regarding as fascination and love for metal as an architectural element. Traditionally, metal has given people an impression of being hard, heavy, and rigid, such as steel columns and steel beams. However, I believe metal can also be soft yet strong, free and dynamic, lightweight but capable of bearing weight. Imagine walking through a space and being captivated by surfaces that reflect different lusters as you move, creating images that cannot be perceived at a glance. I want to utilize the inherent qualities of metal, such as its luster, malleability, and recyclability. Through complex processing, I aim to showcase its diversity, propose innovative structural forms, and create a spatial atmosphere where the material speaks for itself.

In architectural space, metal sheets are often used as cladding or exterior without structural support, requiring additional substructures for attachment. If these two aspects could be combined, it would not only reduce the amount and weight of materials but also shorten the construction time. Therefore, I am contemplating how to transform paper-thin metal sheets into extremely rigid structural materials through processing that changes their shape. This approach aims to achieve both structural integrity and aesthetic significance. The stark contrast between the lightweight texture and the robust functionality reinterprets the contemporary nature of the material.

The designer has produced physical models, demonstrating that the design has high development potential. Future plans include applying this design in various scales: small scale such as furniture, tables and chairs, display racks; medium scale such as exhibition spaces, public art, interior decoration; and large scale such as structural systems for public works, building facades, and roofs. Additionally, the plan is to use this design form as a template for concrete casting, taking advantage of the high durability and long lifespan of metal plates. This aims to replace the issue of non-reusable wooden templates in the construction field, striving towards the goal of a sustainable environment.

2023

Through structural analysis and algorithmic optimization, the goal is to reduce the material area and quantity, achieving the lightest yet most stable structure. By using robotic arms for single-point incremental forming—a process similar to traditional stamping and spinning—the advantage lies in producing an unlimited variety of bespoke shapes without the high cost of fabricating moulds. The design strategy of double-layer interlocking arrangements enhances overall strength, while similar but non-repetitive conical forms interconnect to generate thickness, combining both aesthetic and structural significance. Within this space, one can enjoy a rich and dynamic experience with changing light and shadow. Moving to the side, one can appreciate the material's aesthetic of being both soft and strong.

Student: Hao Cheng, Wang

Supervisor: Hong Ming, Cheng

Favorited 1 times