The No Footprint House (NFH) is located in Ojochal, a small village at the edge of the vast tropical rain forests along the southern Pacific coast of Costa Rica. The building responds to its surrounding habitat by passive climate control through natural ventilation and solar shading according to the principles of bioclimatic architecture. The NFH is organized around a central service core, which includes all machinery and intelligence, as well as the bathrooms, kitchen and laundry area. The compression of utilities in one compact unit enables an open floor plan all around the core, a design strategy that contributes to the building efficiency in terms of assembly, maintenance and use. Slanted facades decrease the direct impact of sunlight and precipitation. Individual panels can be opened or closed in order to regulate views and exposure, augment or reduce air flows, create privacy and security. The operable facade sections convert interior to exterior spaces and play with the dynamic among nature and the built environment, one of the key features in tropical architecture. The modular prefabricated home is developed as a prototype for serial production, based on a systemic catalogue for sustainable residential typologies. A wide range of affordable, customizable and replicable solutions is catering for a broad customer segment. The NFH is designed to minimize the impact of construction and merge with its natural surroundings, seeking integral sustainability in terms of its environmental, economic, social and spatial performance.

2017

2018

The No Footprint House, or simply NFH, has numerous inspirations. It is largely rooted in the work of professionals who were looking for combined solutions in architecture and engineering, further paired with a broader world view towards sustainable development. For example, the Dymaxion House by Buckminster Fuller was a crucial influence for us, as well as the groundbreaking work of Jean Prouve in terms of his prefabricated systemic designs for different climates, such as the Maison Tropicale. Further inspiration was found in the contemporary automotive industry.

In its initial phase, the NFH comes in three different sizes that can be auto-configured with regards to the internal distribution and connections, material finishes and desired level of services: from tiny to mid-size and family home. Tailor-made typologies can be offered, including self-sufficient solutions for off-grid locations. The selection of all elements and materials from our catalog of prefabricated components is based on a thorough investigation regarding their origin, processing, cost and environmental footprint. They can be chosen according to the site-specific requirements and client needs.

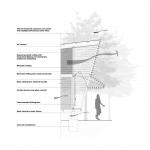

The built prototype is based on a structural grid size of 12x9 meters, which are broken down into prefabricated units of 3x3 meters each. The central service core measures 6x3 meters, containing 2 bathrooms and all technical equipment of the house. With cantilevering and double-height floor areas, the building totals 150 square meters for two bedrooms, kitchen, dining, living and terrace areas. It is designed as a spacious residence for one family. Alternative pre-designed typologies for individuals and small families are available. Individual layouts can be configured and produced upon demand.

The prototype was built with a structural steel frame and pine wood finishes. It was prefabricated in the Central Valley of Costa Rica and delivered to its target-site on one single truck. We are currently developing additional structural systems in order to amplify the configuration options for our clients and to continue improving the project performance. One of these alternative systems is based on laminated and solid teak wood components, which will be produced and processed in Costa Rica. The different product lines will become available in serial production as of 2022.

The NFH is an ongoing project. The prototype was designed and developed in 2017. It was brought to and tested on site in 2018, documented and communicated in 2019. Since then, we have been working on additional component designs and material solutions to enrich the NFH toolbox and to create solutions for a broad customer segment. With further improvements to the building and operational logistics, we expect to become carbon-neutral by 2022. Furthermore, we intend to extend the production in order to export to other countries while continuing to deliver for the home market in Costa Rica.

The main challenge of the project is to systematize the existing building components that are available on the local construction market. These components are then augmented with imported and self-made solutions to resolve crucial design issues. In the case of the prototype, this was specifically relevant with regards to the inclined bi-fold doors in order to achieve the characteristic and interactive "wrap" or "skin" of the building. Further main challenges were related to the water and energy management system of the project, as well as the prefabrication logistics and on-site delivery.

Lead architect: A-01 / Oliver Schütte

Design team: A-01 / José Pablo González, Mauricio Rodríguez, Misael Rodríguez, Ronald Carvajal, Luuc van Wezel

Typology research: A-01 / Marije van Lidth de Jeude

MEP engineering: Consost / Pablo Mora

Structural design: Ingeniería Cañas / Rafael Cañas

Construction: SLO Studiolocal / Hernán Mora

Photography: Fernando Alda Fotografía / Fernando Alda

Documentary: Manduca Audiovisual / Soren Pessoa, Valeria Romero

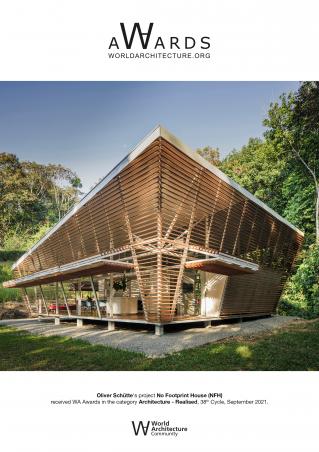

No Footprint House (NFH) by Oliver Schütte in Costa Rica won the WA Award Cycle 38. Please find below the WA Award poster for this project.

Downloaded 0 times.