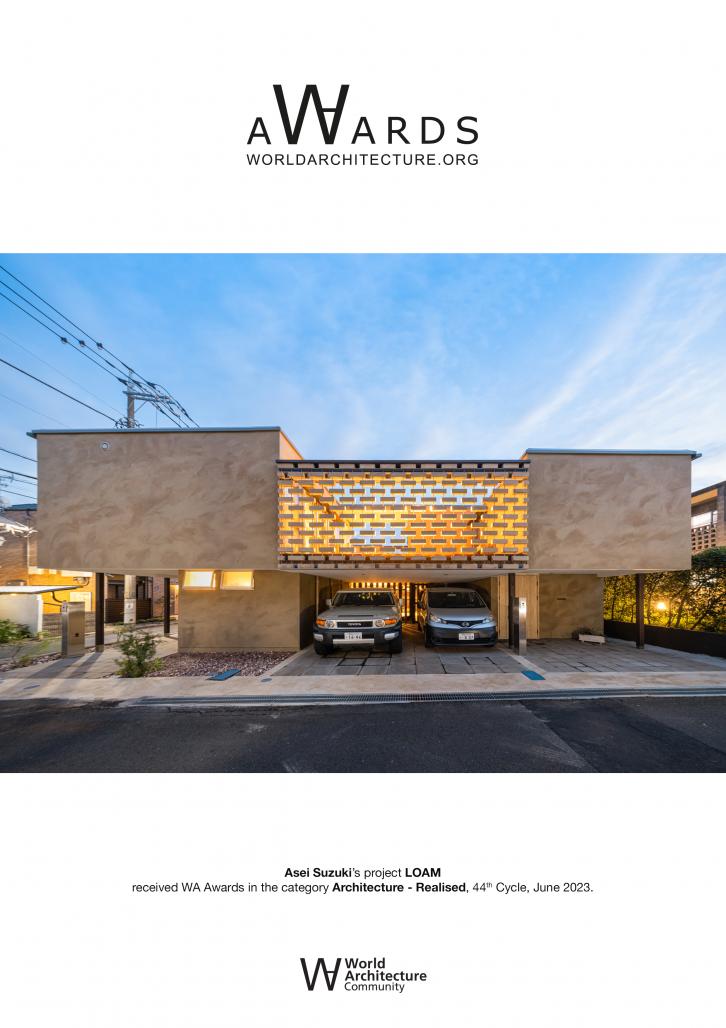

ASEI ARCHITECTS, which develops material development for resource recycling and "Creative Resources" aiming at environmental architecture, has created "Kanto Loam", which has become a social problem due to inappropriate disposal of construction soil. For the first time in Japan, we succeeded in manufacturing and developing Kanto loam bricks. In this house, the Kanto loam bricks were used for the interior and exterior walls and floors, and 5 tons of Kanto loam was recycled.

【Title】

Tokyo's two-family house "LOAM", which uses Kanto loam as construction material for the first time, is completed!

【Subtitle】

Realizing a comfortable thermal environment by making use of Kanto Loam's heat insulation, moisture absorption and release, and heat storage properties

【What are creative resources? 】

Creative resource refers to discovering value in the resources that are lying dormant in the region and the resources that are discarded in the city. This is a demonstration experiment project aiming to realize sustainability. Members are a team of architects, structural engineers, researchers, manufacturers, manufacturers, engineers and craftsmen.

【Utilization of unused construction soil as building material】

In 2016, our creative resource development team, which continues to work on the utilization of unused resources, focused on the unused resource that spreads around the Kanto region called Kanto Loam. In this year, the Tokyo Metropolitan Government revised the "Tokyo Construction Recycling Promotion Plan," which was formulated as a new system based on the situation surrounding construction resource recycling, and announced that it would aim for a 95% recycling rate of construction soil by the Olympic Games. . However, according to the Tokyo Metropolitan Government's announcement in April this year, the actual value of the construction soil recycling rate was 70%, and it was updated to aim for 88% by FY2024. Most of the reuse is for backfilling in civil engineering work, and in construction, the situation continues that the utilization promotion is not progressing due to the trouble of stabilizing treatment such as removal of gravel and organic matter. For more than 5 years, we have been making prototypes of blocks, bricks, and plastering that contain Kanto loam, with the aim of recycling construction soil by turning it into a building material. At the same time, we are also conducting research on the structure and space that make use of the characteristics of the materials developed at the same time. This project was the first attempt at housing.

【About Tokyo's two-family house "LOAM"】

The residential area of Setagaya-ku, Tokyo, where the site is located, has many private roads and designated roads, and is densely packed with blocks that share roads. It has become a townscape that you can feel. Originally, two grandparents lived on the site, but when my grandfather passed away, it was decided to rebuild it into a two-family house with my son and his wife. Since the land is relatively large in Tokyo, in order to avoid a building that divides the land into small pieces by household, two households are connected to the north and south, and the street is led between the two buildings to increase the volume. We share a "three-dimensional alley" made by flying geese. You can keep your family connected and distanced through the nature that intervenes in the alley. Each space in both buildings looks multi-layered through the alleyway, creating a space for walking around the site environment.

【A comfortable life that takes advantage of the characteristics of Kanto loam】

Kanto Loam is a clay soil with high heat capacity and high heat storage. In addition, due to the aggregated structure in which multiple particles have cavities inside, it has many characteristics such as high heat insulation, moisture absorption and release, water retention, and drainage. On the south side of the terrace and on the north side of the common terrace, Kanto loam bricks, which are made by mixing Kanto loam soil with silica sand and cement, pressurizing it, and firing it, are hung like Edo blinds to create moderate privacy. We are striving to control solar radiation. The three-dimensional alley surrounded by the Kanto loam flat brick floor and walls with Kanto loam mixed plastering is also a wind tunnel. and bring it into the room, fulfilling the function of thermal conditioning. I hope that Kanto Loam, an unused resource in Tokyo, will become a new medium that brings nature to life and connects family relationships.

【About future development】

We are currently measuring the temperature and humidity of indoor and outdoor thermal environments using Kanto loam bricks. Based on the results of the demonstration experiment at this house, we will further promote the manufacturing and development of blocks, tiles, bricks, and plastering using Kanto loam, aiming to expand the recycling of construction soil. In addition, we plan to work on visualizing the resource recycling system and greenhouse gas reduction effect through this initiative.

2021

2022

Location: Soshigaya, Setagaya Ward, Tokyo, Japan

Main use:Two-family house

Family composition: Grandmother son and wife 2 grandchildren

Number of floors: 2 floors above ground

Eaves height: 5,68m Maximum height: 5,80m

Site area: 239.92m2

Building area: 141.34m2 (Building coverage ratio 58.91% Allowable 70%)

Total floor area: 193.88m2 (Floor area ratio 80.81% Allowable 150%)

1st floor: 79.26m2

2nd floor: 114.62m2

Design period: February 2020 to October 2020

Construction period: November 2021 to August 2022

Architects: ASEI ARCHITECTS & Asei Suzuki

Structural design: yAt Structural Design Office

Contractor: SS Co., Ltd.

Material development: Stone Works Inc.

Photo: KATSU TANAKA

LOAM by ASEI SUZUKI in Japan won the WA Award Cycle 44. Please find below the WA Award poster for this project.

Downloaded 0 times.