Submitted by WA Contents

Zaha Hadid Architects reveals the silk-inspired bridge of Hangzhou with a sinuous form

China Architecture News - Oct 30, 2025 - 05:52 4146 views

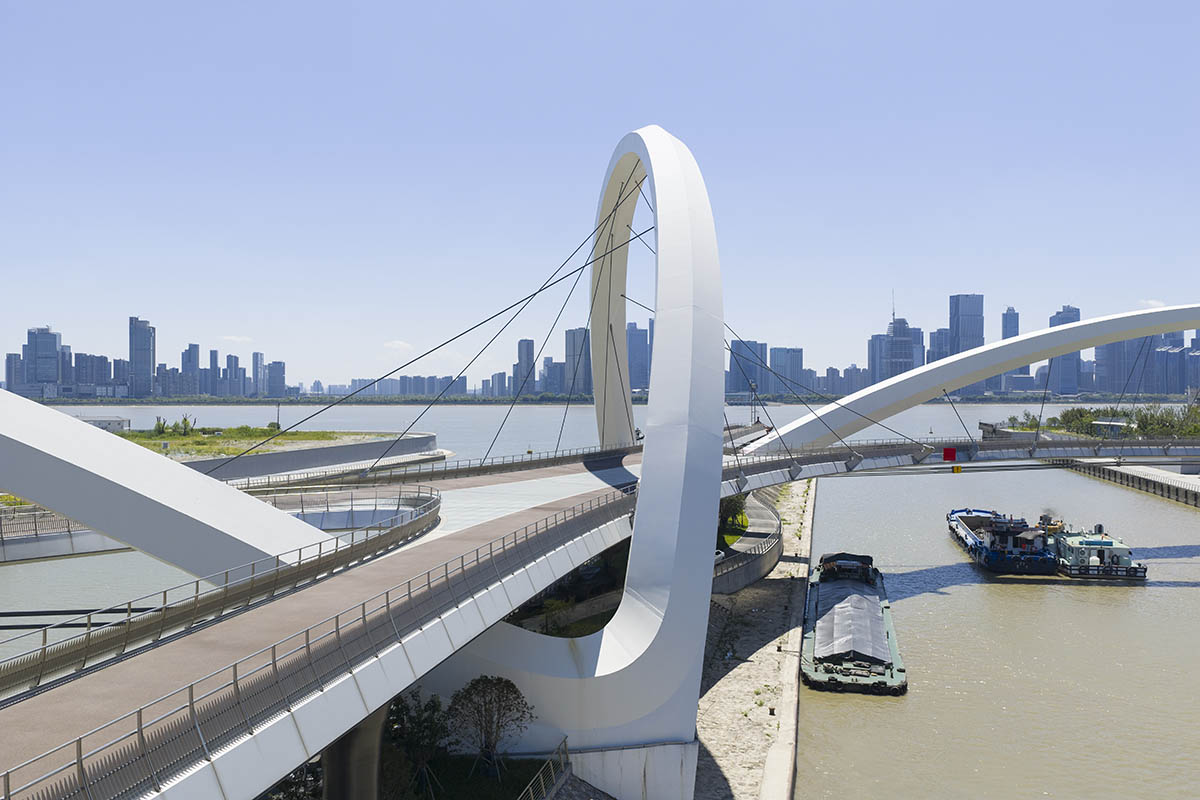

Zaha Hadid Architects has revealed the silk-inspired bridge of Hangzhou with a sinuous form in Hangzhou, China.

The footbridge connects the 800,000 square meter Seamless City project being built on the Grand Canal's east and west banks when it opens for public use later this year.

The bridge and surrounding masterplan by Zaha Hadid Architects, the focal point of the city's new 14.7-hectare River Middle public park and river promenade, reconnects the city with its historic Grand Canal and Qiantang River by fusing residential and commercial structures with essential civic areas for leisure, recreation, and tourism.

The Grand Canal, which flows south from Beijing to connect with China's Yellow and Yangtze Rivers before joining the Qiantang River at its southern gateway in Hangzhou, is China's oldest and longest man-made waterway and a UNESCO World Heritage site. It is an amazing engineering achievement dating back to the fifth century BC.

The Silver Dragon, the largest tidal bore in the world, is a famous feature of the Qiantang River in Hangzhou. It is created when incoming tides from Hangzhou Bay surge upstream, producing waves that can reach a height of nine meters and move at a speed of forty kilometers per hour.

The bridge's walkways and plaza, which strike a balance between ecological consciousness and civic aspirations, offer a variety of vantage locations from which guests can safely take in the spectacle and sheer might of the Silver Dragon's natural force.

The design reinterprets traditional stitching techniques, drawing on Hangzhou's longstanding legacy as a center of excellence for China's famed silk embroidery.

In order to sustain a bridge for bicyclists and walkers connecting the new residential, civic, and commercial districts of Hangzhou's Seamless City design on the east and west banks of the Grand Canal, its winding structural system weaves, overlaps, and binds.

The Grand Canal Gateway Bridge used prefabricated modular construction with effective on-site assembly to save waste, and it was optimized by sophisticated digital 3D modeling to minimize material usage.

The Grand Canal, which is currently utilized by 100,000 barges annually to transport 260 million tons of cargo sustainably within China, was the focus of the bridge's building plan, which was particularly created to reduce development time and minimize disruption to river activity.

By utilizing low-impact finishes and locally produced materials, the project promoted sustainable building practices and localized production through teamwork.

The bridge is illuminated at night by integrated LED lighting that is powered by banks of batteries that are charged throughout the day using renewable energy.

The steel, connected three-arch structure of the 390-meter-long bridge is specifically designed to solve the poor ground conditions at the Grand Canal and Qiantang River confluence.

The design ensures stability and minimizes lateral stresses inside the foundations by reducing secondary bending and preventing the strong wind forces that blow inland from the river from transferring to the delicate historic site.

The bridge is far lighter than concrete alternatives thanks to the excellent strength-to-weight ratio of steel, allowing for the most effective construction and installation procedures.

The bridge lands on a sculpted concrete pier inside the island that divides the canal's north and south waterways. It is designed to consolidate all forces, including torsion from the deck, and deliver them in balance to its bearings, halving the necessary spans to cross the canal while maintaining structural equilibrium and aesthetic coherence.

The Grand Canal Gateway Bridge, which combines 21st-century engineering and recyclable materials with cultural history, is long-lasting and environmentally friendly.

Zaha Hadid Architects also completed the Jiangxi River Bridge made of "dynamic curves" crossing the Jiangxi River in Chengdu, China.

Additionally, the firm together with the Block Research Group (BRG) at ETH Zurich and Zaha Hadid Architects Computation and Design Group (ZHACODE), in collaboration with incremental3D (in3D) and Holcim completed an arched masonry footbridge at the Giardini della Marinaressa in Venice, Italy.

Project facts

Client: Hangzhou CBD Development Group, ltd.

Architect: Zaha Hadid Architects (ZHA)

ZHA Principal: Patrik Schumacher

ZHA Project Directors: Paola Cattarin, Paolo Matteuzzi

ZHA Project Architect: Maria Loreto Flores

ZHA Concept Project Architect: Saman Dangostar

ZHA Concept Design Team: Berkin Islam, Christy Yin, Delfina Bocca, Enoch Kolo, Federico Borello, Hunter Paine, Irena Predalic, Kalliopi Mouzaki, Lorena Espaillat Bencosme, Luciano Letteriello, Marcella Fedele, Maria Tsironi, Mariagrazia Lanza, Mariana Custodio Dos Santos, Marie-Perrine Placais, Mattia Santi, Michael On, Milind Khade, Miron Mutyaba, Mohamed Al-Jubori, Nastasja Mitrovic, Natasha Marks, Philipp Siedler, Pierandrea Angius, Qiuru Pu, Raquel Arauco Ordas, Saman Dadgostar, Satoshi Ohashi, Shahd Abdelmoneim, Shajay Bhooshan, Sven Torres, Thomas Bagnoli, Tommaso Casucci, Vincent Konate, Vincenzo Barilari, Vishu Bhooshan, Xiaoyu Zhang, Yuan Zhai, Yuzhi Xu

ZHA Design Team: Andy Lin, Damir Alispahic, Effie Nakajima, Gaganjit Singh, Gigi Ho, Hangyul Jeong, Iris Chen, Joanna Saade, Jose Castaneda, Kalliopi Mouzaki, Ke Yang, Maria Echeverri, Milica Pihler-Mirjanic, Millie Anderson, Miron Mutyaba, Natasha Tariq, Qiuru Pu, Stefano Iacopini, Xuan Zhao, Yuan Zhai

Grasshopper definition: Gaganjit Singh, Miron Mutyaba, Qiuru Pu

Artistic Supervision: Qiuru Pu, Gaganjit Singh, Miron Mutyaba, Xuan Zhao

Consultants

LDI: Tongji University Architectural Design Research Institute (Group) Co., Ltd

Structural Engineering: Schematic Design: Arup. Preliminary Design – Construction Documentation: Tongji University Architectural Design Research Institute (Group) Co., Ltd

Landscaping & Lighting: Tongji University Architectural Design Research Institute (Group) Co., Ltd

General contractor: Hangzhou Xiaohong Construction Environment Group Co., Ltd.;

Third-party monitoring unit: Zhejiang University.

Steel Fabricator: Hunan Valin Iron and Steel Co., Ltd.

All images © Xue Liang.

> via ZHA