Submitted by

Achim Menges And Jan Knippers' Team Install "Maison Fibre" At Venice Architecture Biennale

teaserc-79-.jpg Architecture News - May 28, 2021 - 16:24 2592 views

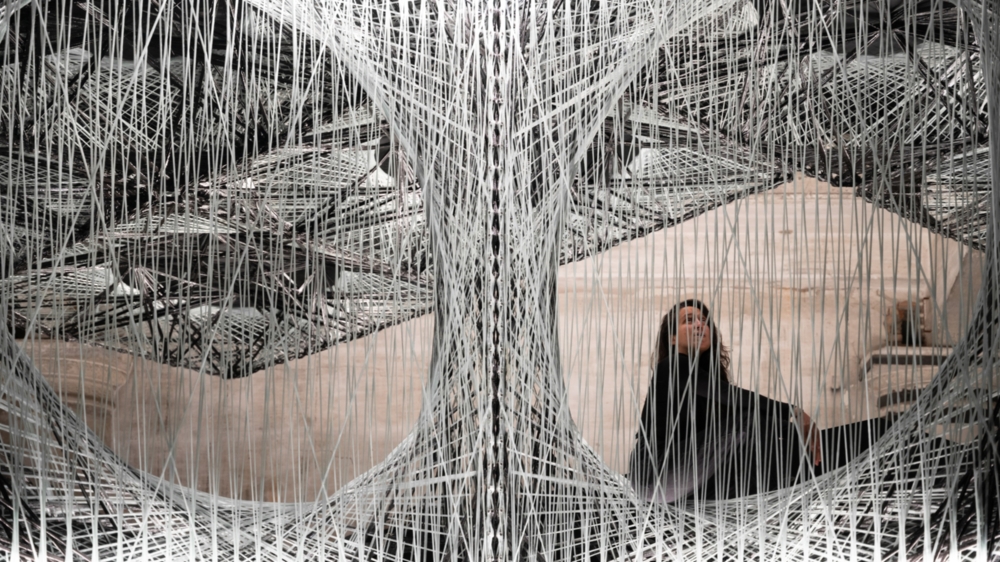

German Professor Achim Menges and Professor Jan Knippers' team has installed a robotically-designed and constructed "Maison Fibre" at the Arsenale venue of the 2021 Venice Architecture Biennale which opened to the public on May 22 in Venice, Italy.

Developed with the Institute for Computational Design and Construction (ICD) and the Institute of Building Structures and Structural Design (ITKE) of the Cluster of Excellence IntCDC at the University of Stuttgart, the full-scale inhabitable installation has been made entirely from robotically produced, fibrous building elements.

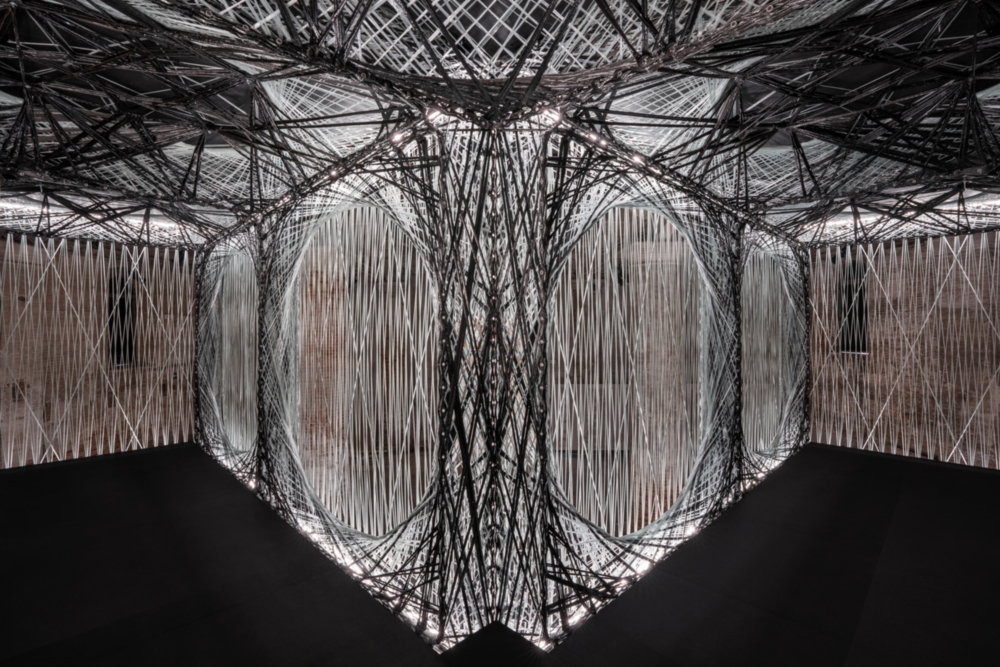

The installation is "the very first multi-story structure of its kind", which explores an alternative material approach to the design and construction of future habitable spaces.

Video courtesy of Institute for Computational Design and Construction (ICD), University of Stuttgart.

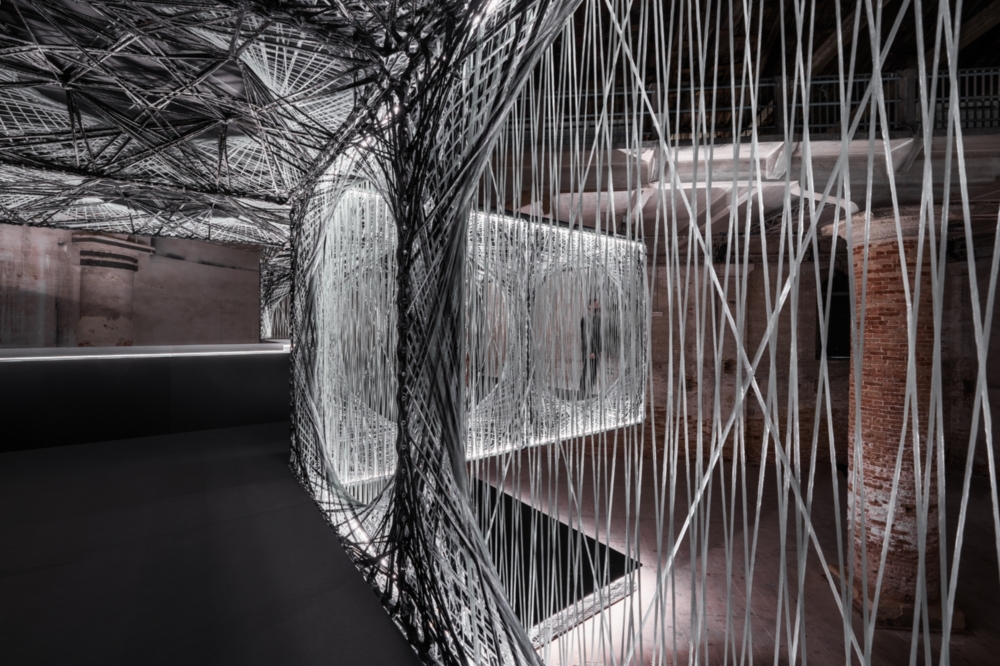

Another important difference of the installation is its possible adaptability and can have an interaction with the existing building stock, which can be decisive for future urban buildings.

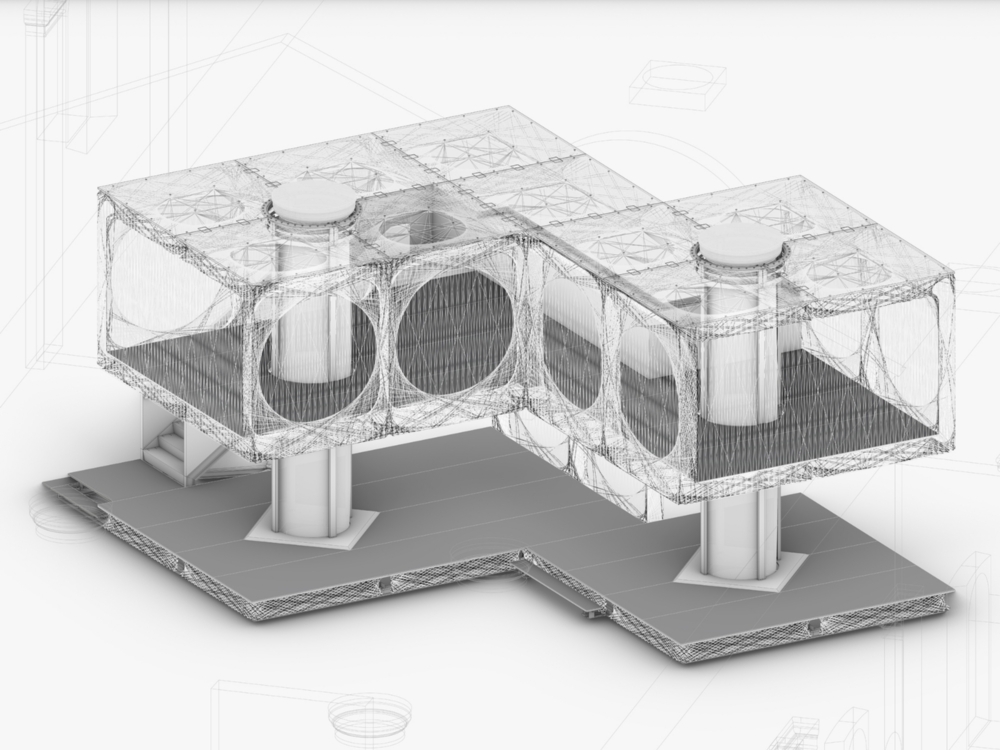

At the Arsenal venue, the structure is deliberately emphasized by integrating the existing columns of the Arsenale building.

In response to Hashim Sarkis' theme "How will we live together?", the installation allows visitors to have an intense material experience and spatial expression of future, highly dematerialized structures.

The aim of the Maison Fibre is to show that "each building element can be locally made from just a few kilos of construction material," without extracting materials from faraway places that cause to reduce the footprint of humans in every action.

Featuring inhabitable fibrous floor slabs and walls, the installation is comported to Le Corbusier’s Maison Dom-Ino as a role model for 20th century architecture, the Maison Fibre installation, a highly dematerialized structure, weighs 50 times less than Le Corbusier’s Maison Dom-Ino structure.

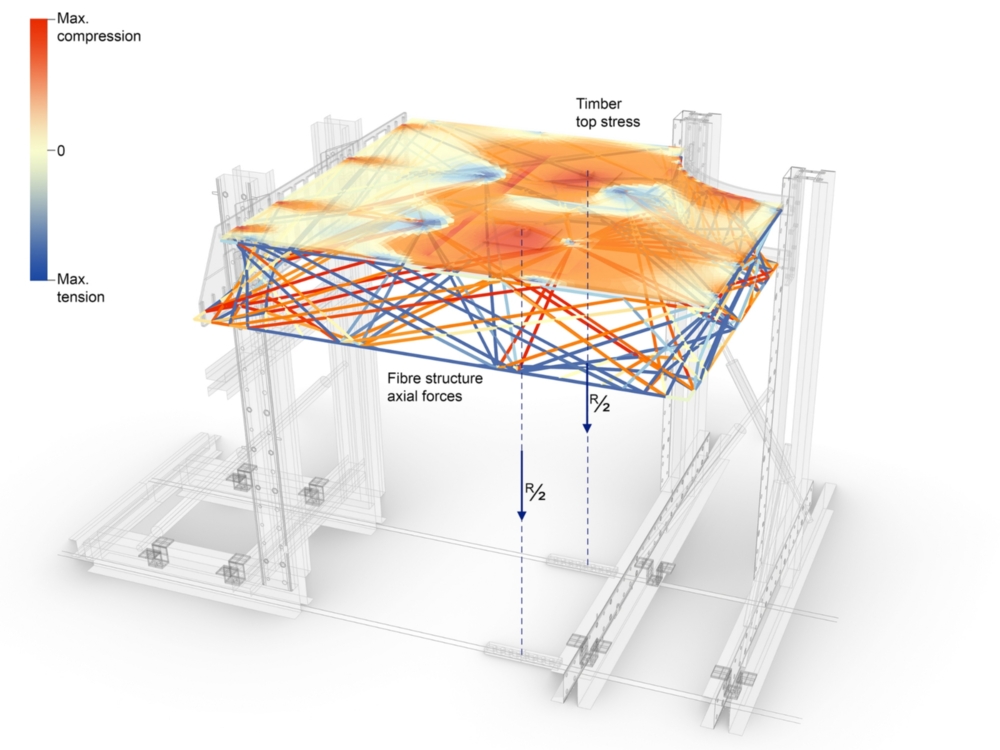

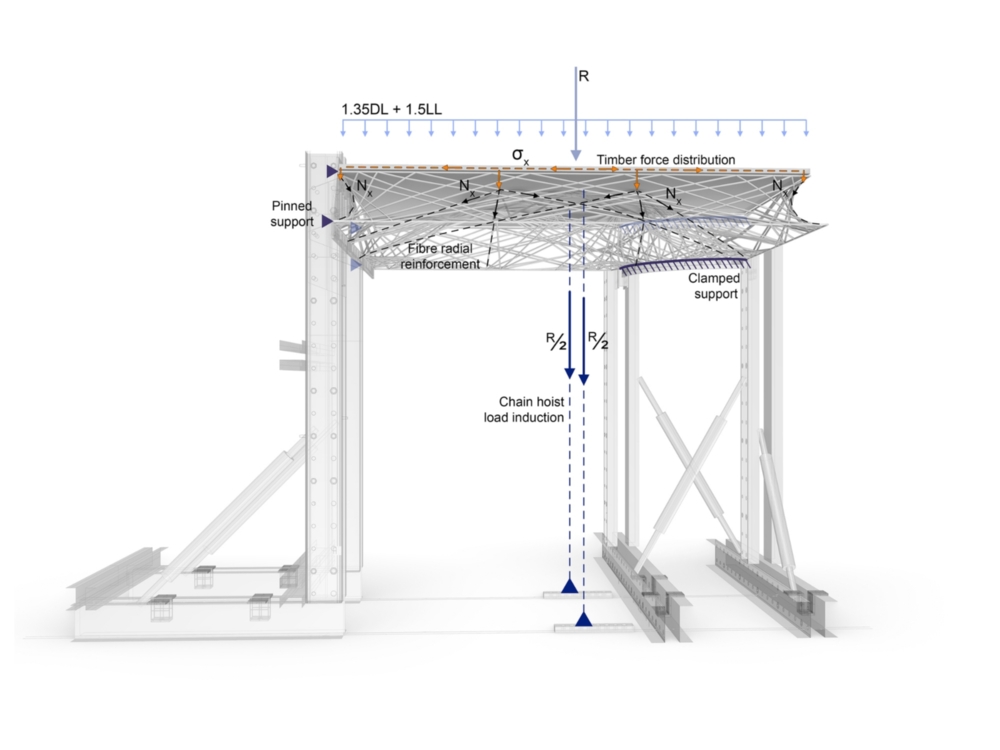

"The code-compliant, load-bearing fiber structure of the upper floor weighs just 9,9 kg/m². The wall elements are even lighter," said the team.

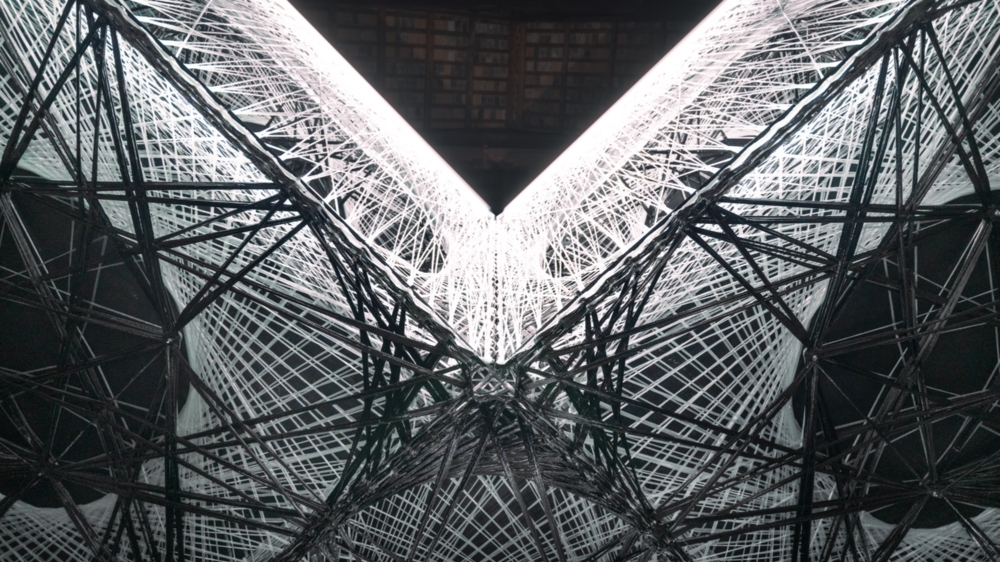

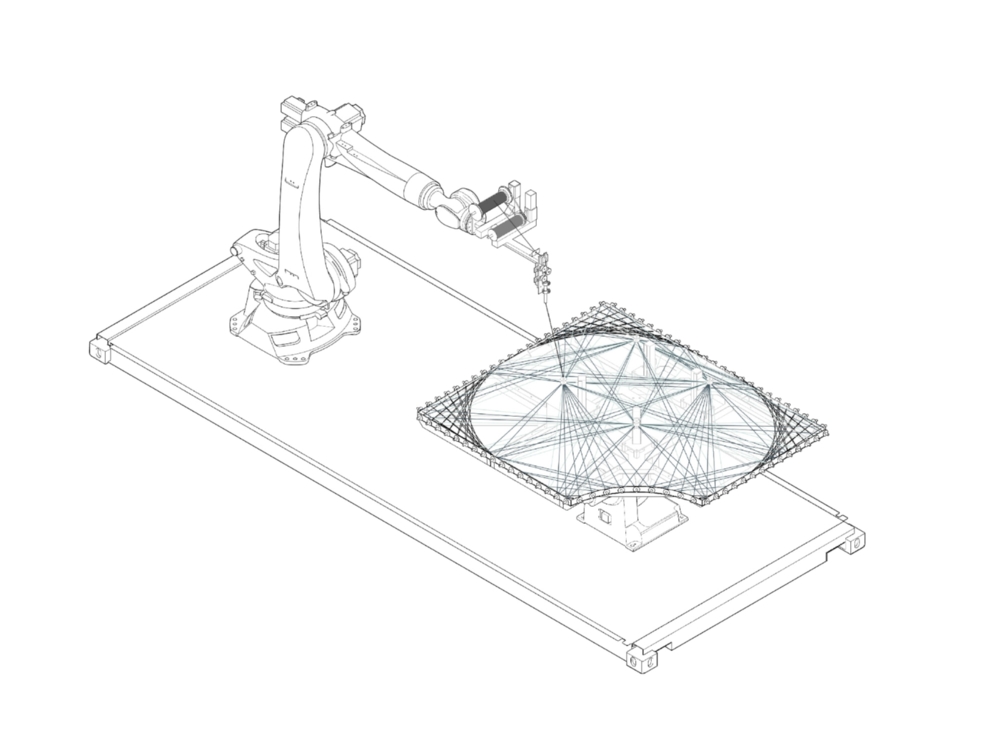

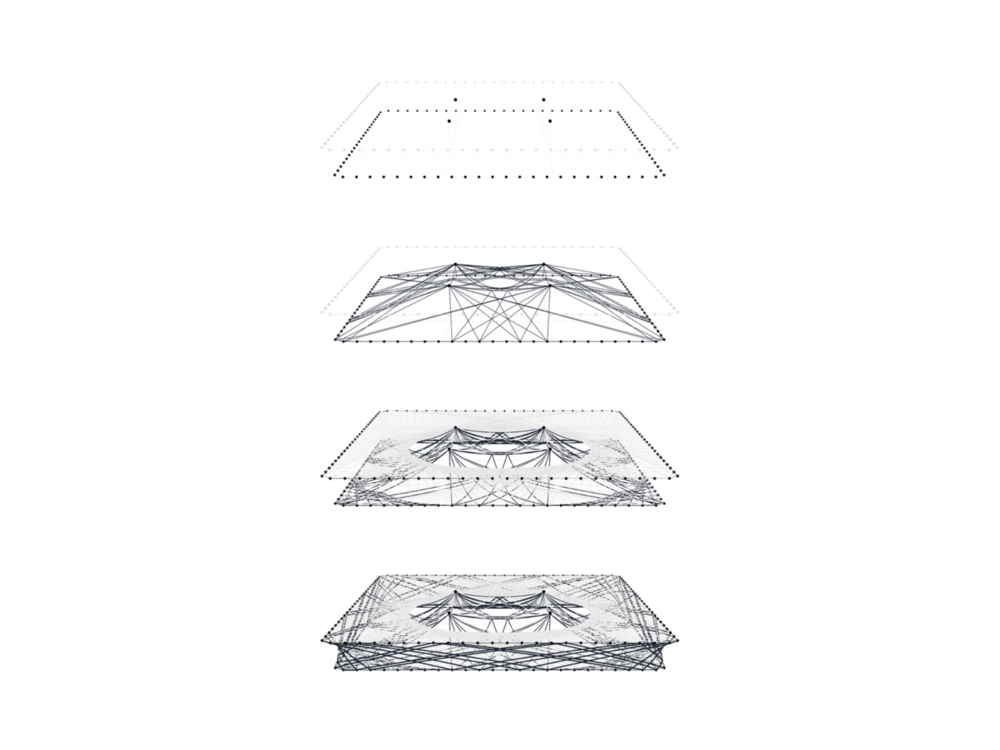

"The fibrous wall and ceiling elements were manufactured using the coreless, robotic winding process developed by the project team, which allows for locally load-adapted design and alignment of the fibers, thus enabling an extraordinary lightweight construction," the team added.

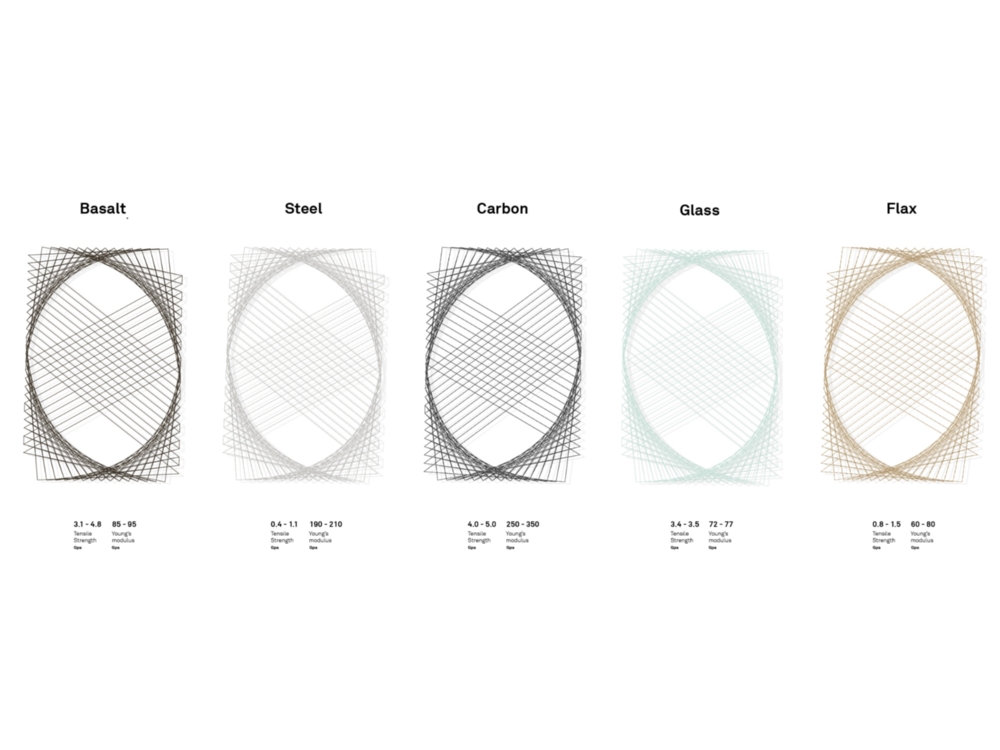

The entire structure consists exclusively of so-called fiber rovings, essentially bundles of endless, unidirectional fibers.

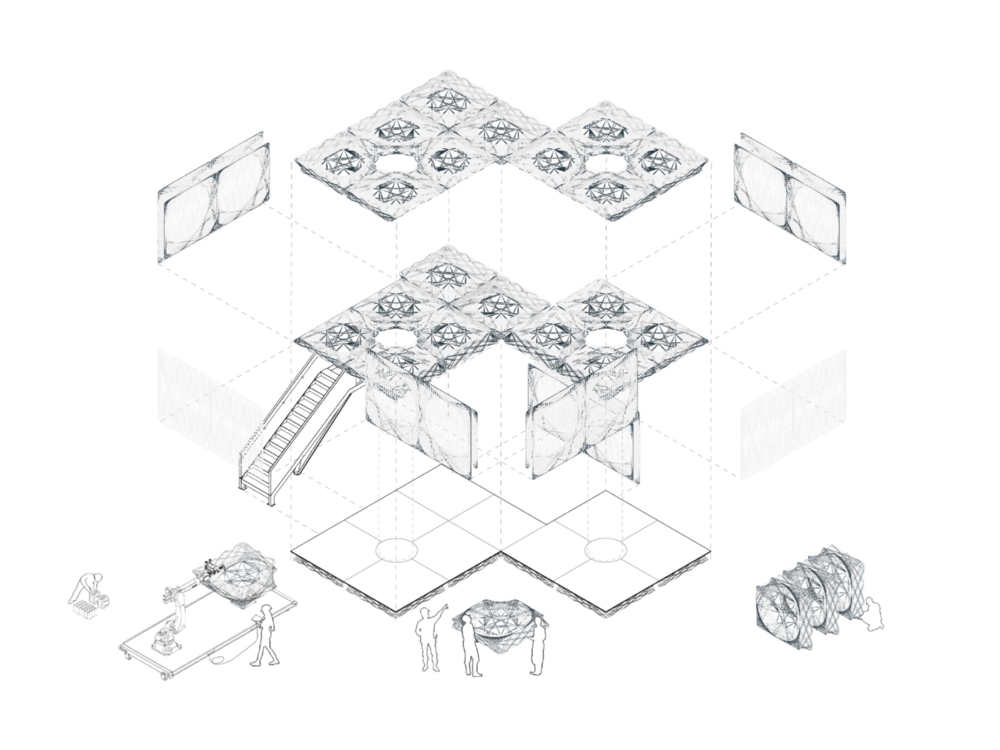

To underline the model character of the project, the team used a system of reconfigurable wall and ceiling elements based on the 2.5-meter grid dimension typical of residential buildings was developed.

"Maison Fibre constitutes a material enquiry of “How will we live together”. It questions the predominant approach of solid construction, which is at the root of the multifaceted environmental and social challenges the building sector is facing, and replaces it with fibrous tectonics, which consume only a fraction of building materials and offer entirely new ways of materialization," said Professor Achim Menges.

"Maison Fibre is the first multi-story, filamentous structure of its kind, made entirely from fiber composites. It is based on an extremely lightweight, genuinely digital building system that could not have been designed or built a few years ago, and heralds a novel material culture in architecture."

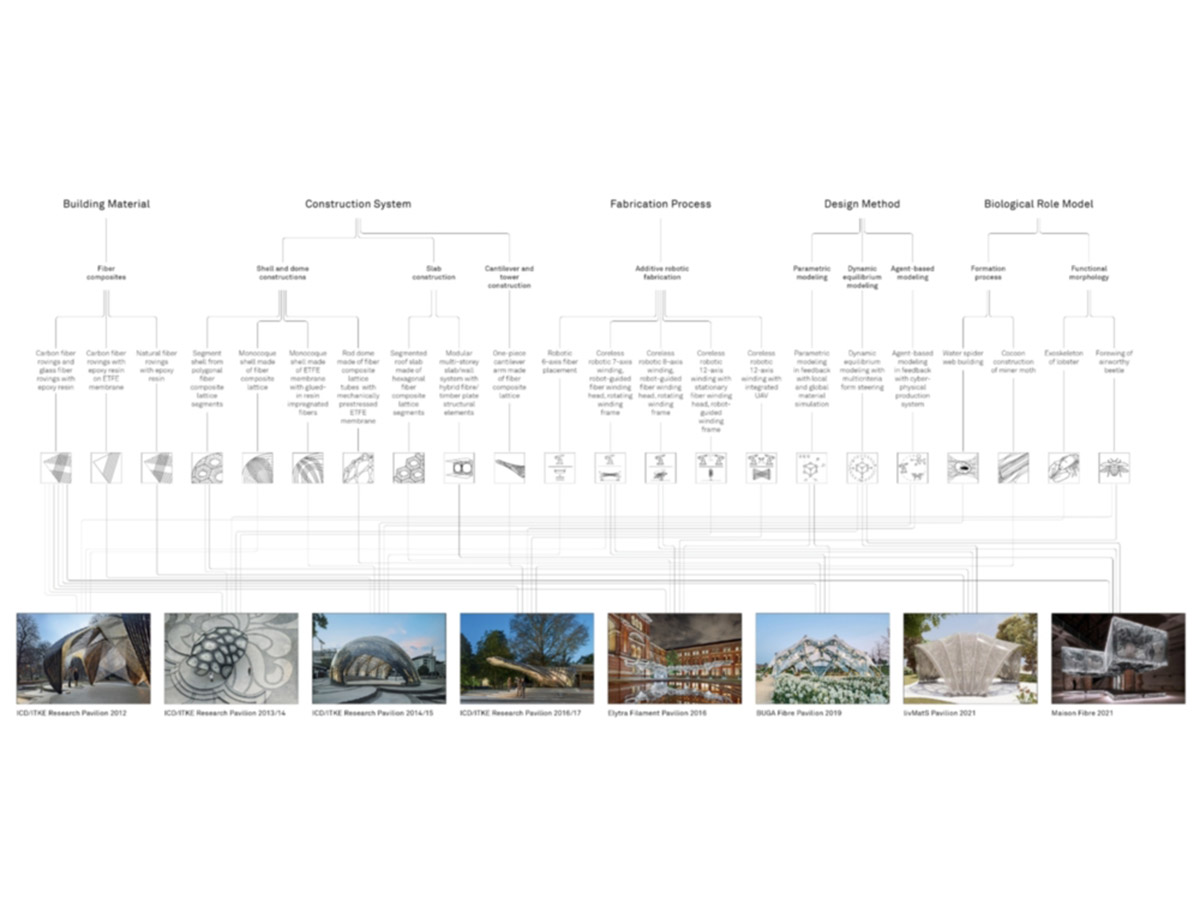

"The study of nature triggers the rethinking of construction in architecture. Biology offers an almost inexhaustible reservoir of principles of form, structure, and process."

"These often question entrenched approaches in architecture and building technology, and offer radically different design possibilities. Maison Fibre demonstrates this in a particularly striking manner," Menges added.

Maison Fibre is described as "towards a material culture of dematerialization", as the installation has been made of currently available glass and carbon fiber systems.

"For the fabrication of a load-bearing floor element, less than two percent of the component volume is required as material volume," said the team.

"This extremely low material consumption coupled with the very compact, robotic production unit could in the future make it possible to carry out the entire production on-site without a significant amount of noise or waste, not only during the initial construction process, but also during expansion or conversions."

"As a result, architecture built using this method will remain adaptable and flexible in the long term," the team added.

The Masion Fibre installation shows itself as the spatial expression and authentic architecture of a highly dematerialized structure.

Considering that building and construction industry are responsible for 38 per cent of all carbon emissions in the world, the installation of Maison Fibre underlines this fact at the exhibition and shows how fibrous systems and fibrous construction are offering a new kind of material approach without producing much waste.

"The process enables on-site fabrication without significant noise or waste. In addition, the weight of the pavilion’s structure is fifty times lower than that of a comparable concrete structure. This makes the assembly much easier, as there is no need for heavy means of transport, scaffolding or lifting equipment," said Professor Jan Knippers.

"This highly innovative construction method is far ahead of existing building regulations. Nevertheless, all the typical functional requirements had to be obtained, which was only possible through extensive analysis and testing," added Knippers.

The 17th International Architecture Exhibition in Venice has opened to the public on 22 May 2021. The exhibition will be on view till 21 November 2021.

This year’s architecture biennale is themed as "How will we live together?" by the curator Hashim Sarkis, the theme explores a widening context that helps architects to "imagine spaces in which we can generously live together".

Project facts

Project Team

IntCDC / ICD University of Stuttgart, Institute for Computational Design and Construction

Prof. Achim Menges

Niccolo Dambrosio, Katja Rinderspacher, Christoph Zechmeister

Rebeca Duque Estrada, Fabian Kannenberg, Christoph Schlopschnat

IntCDC / ITKE University of Stuttgart, Institute of Building Structures and Structural Design

Prof. Jan Knippers

Nikolas Früh, Marta Gil Pérez, Riccardo La Magna

Lab support: Aleksa Arsic, Sergej Klassen, Kai Stiefenhofer

Student Assistance: TzuYing Chen, Vanessa Costalonga Martins, Sacha Cutajar, Christo van der Hoven, Pei-Yi Huang, Madie Rasanani, Parisa Shafiee, Anand Nirbhaybhai Shah, Max Benjamin Zorn.

In collaboration with: FibR GmbH, Stuttgart

Moritz Dörstelmann, Ondrej Kyjanek, Philipp Essers, Philipp Gülke

with support of: Erik Zanetti, Elpiza Kolo, Prateek Bajpai, Jamiel Abubaker, Konstantinos Doumanis, Julian Fial, Sergio Maggiulli.

Project Support

University of Stuttgart

Cluster of Excellence IntCDC, EXC 2120

Ministry of Science, Research and the Arts, Baden-Württemberg

GETTYLAB, Teijin Carbon Europe GmbH, Elisabetta Cane with Bipaled s.r.l. – Annalisa Pastore, Trimble Solutions Germany GmbH.

Project Data

Building System:

Two-story, robotically fabricated, load bearing glass- and carbon fiber composite structure made of 23 km of glass fibers total and 20 km of carbon fibers total

Dimensions Length/Width/Height: 10,00m / 11,78m / 5,76m

Floor Area: 125 m² total and 62,5 m² per floor

Weight of load-bearing fiber composite structure: 9,9 kg/m² for inhabitable first floor

Weight of load-bearing fiber composite structure including 27 mm timber floor panels: 23,7 kg/m² for inhabitable first floor

Weight comparison to regular 200 mm thick concrete slab:

Load-bearing fiber composite structure: 50x lighter

Load-bearing fiber composite structure including timber floor panels: 21x lighter

Material Volume Ratio: 1,9% material volume per slab volume

All images © ICD/ITKE/IntCDC/University of Stuttgart

> via Institute of Building Structures and Structural Design