Submitted by Sarbjit Bahga

Serving Agriculture Through Architecture: Punjab Builds India's First Maize Dryers

India Architecture News - Dec 05, 2017 - 13:15 21733 views

Punjab is an agrarian state having paddy and wheat as its main crops. Due to plenty of these food grains, the central and state governments are pursuing the farmers to diversify their crop pattern and adopt maize as one of the major alternative crop. The maize crop in Punjab is presently facing a serious marketing problem due to high percentage of moisture content in the grains.

The moisture percentage in the grains at the time of harvesting season is up to 28% but actual requirement of moisture for proper storage and processing is 14% approximately. This results in low price of the crop. The sun drying during this period is not practically possible because it coincides with the monsoons; moreover sun drying is not uniform.

To cope with this problem, the Punjab State Agricultural Marketing Board has established number of Maize Dryers at Saila Khurd, Nawanshahr, Machhiwara, Bhogpur, Hoshiarpur and Kapurthala. It is envisaged that 20 more such dryers shall be established in the state in near future.

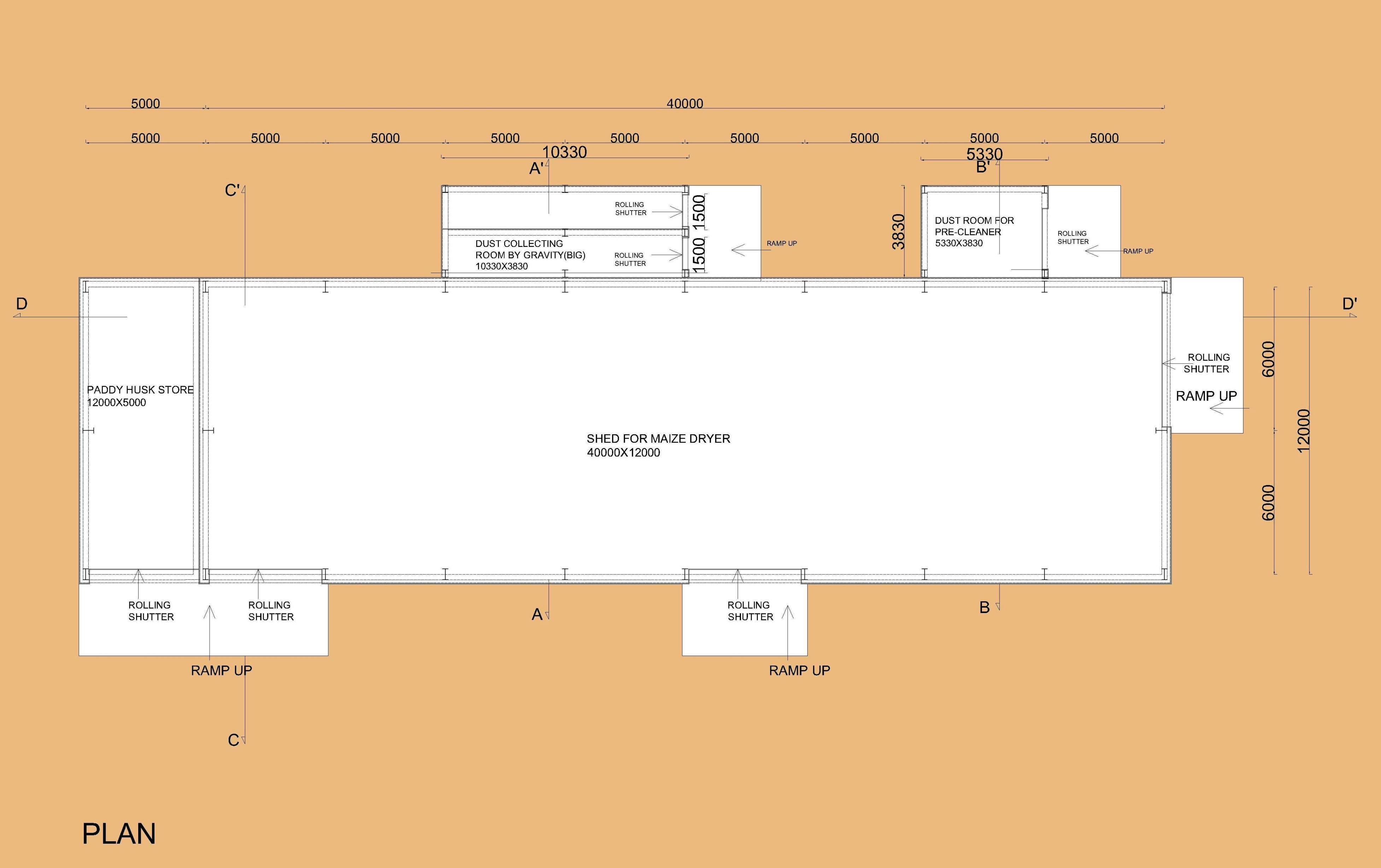

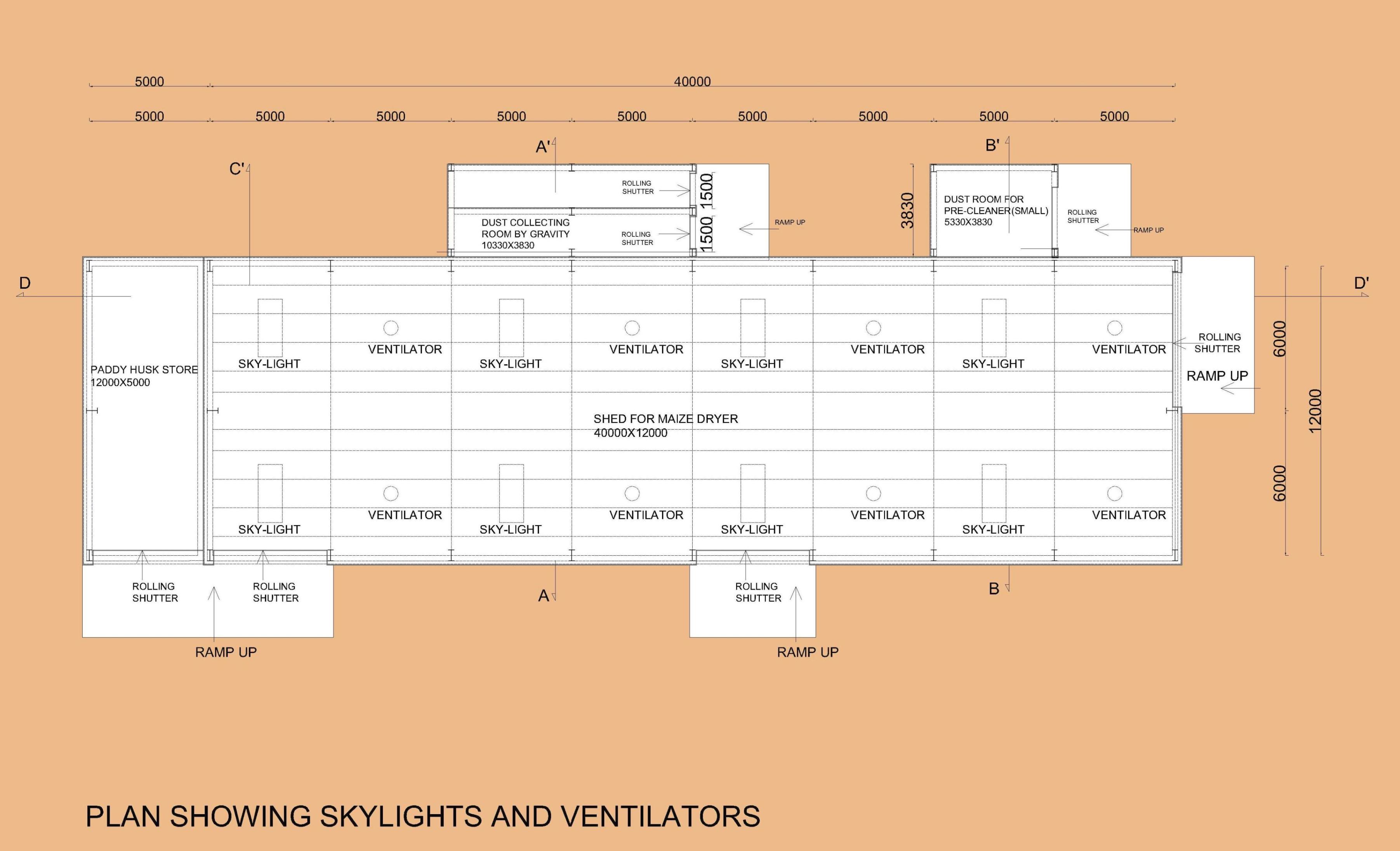

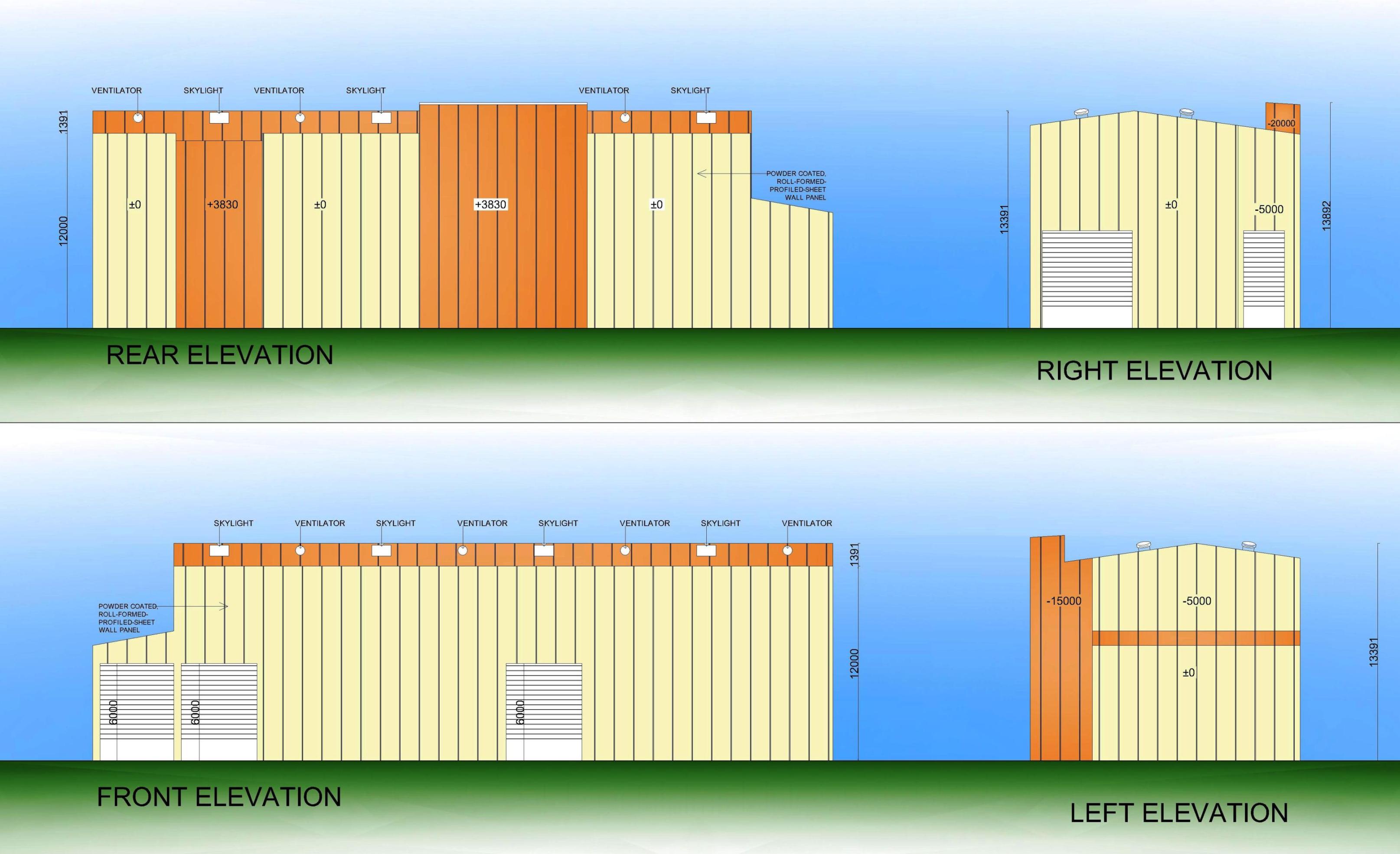

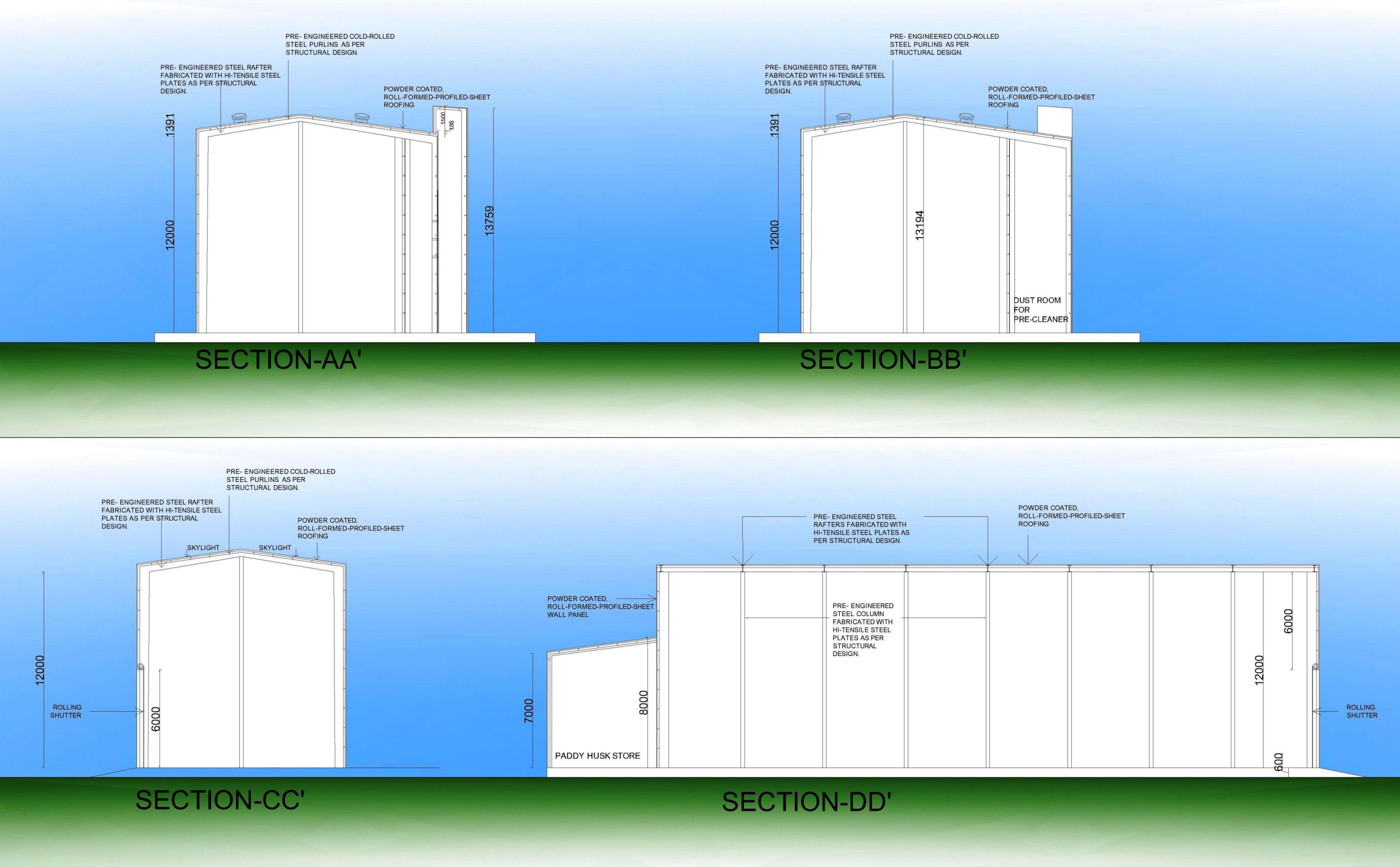

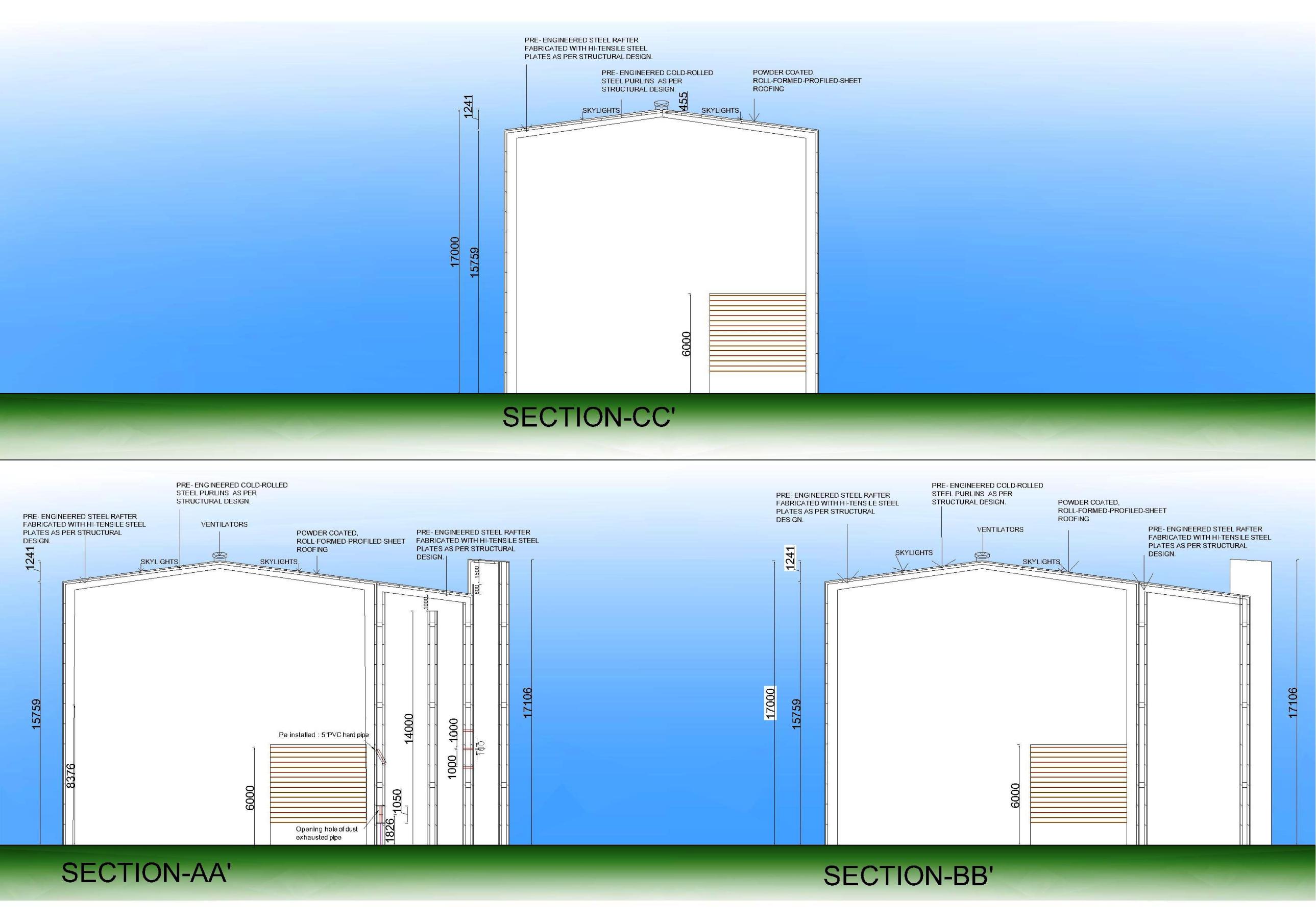

Maize Dryer Centres have been constructed in high-tensile, pre-engineered steel structure with powder-coated profiled sheets. Two types of designs have been prepared for these Centres. The bigger ones have a volume of 48m x 18m x 17m and the smaller ones have a volume of 40m x 12m x13m.

Structures have been designed to house large dryer plants manufactured by Suncue Company of Taiwan. For drying of grains, heat is produced by burning rice husk in a furnace which is attached to units. Using rice husk instead of diesel is more economical, energy saving and environment friendly.

To design a large structure for such a plant was a gigantic task for the architect Sarbjit Bahga more so when there was no such prototype available in India. Considering the volume of the building envelope and time constraint, the architect ruled out the options of conventional structures in brick or concrete.

Instead he chose to go in for pre-engineered steel building (PEB). The PEB structure has numerous plus points as compared to conventional structures. It is easy to construct, fast to construct, economical, and more precise. The time taken for the whole structure after foundations was less than two months.

The factors taken into account while designing the structure were serviceability, wind pressure and of course, structural stability. To design such a large, voluminous building was really a challenging task for the architect and the structural engineer. The success of the project lies in the well-coordinated efforts of all the team members.

Though the dominant factors for designing such a farm/industrial building were serviceability and structural stability, yet the architectural aesthetics vis-à-vis proportions and colour scheme were also on top of the mind of the architect.

Since these were the first such maize dryers in India, the architect wanted them to be iconic structures, which not only Punjab but the whole country should feel proud of. And assessing their success story, it is true also.

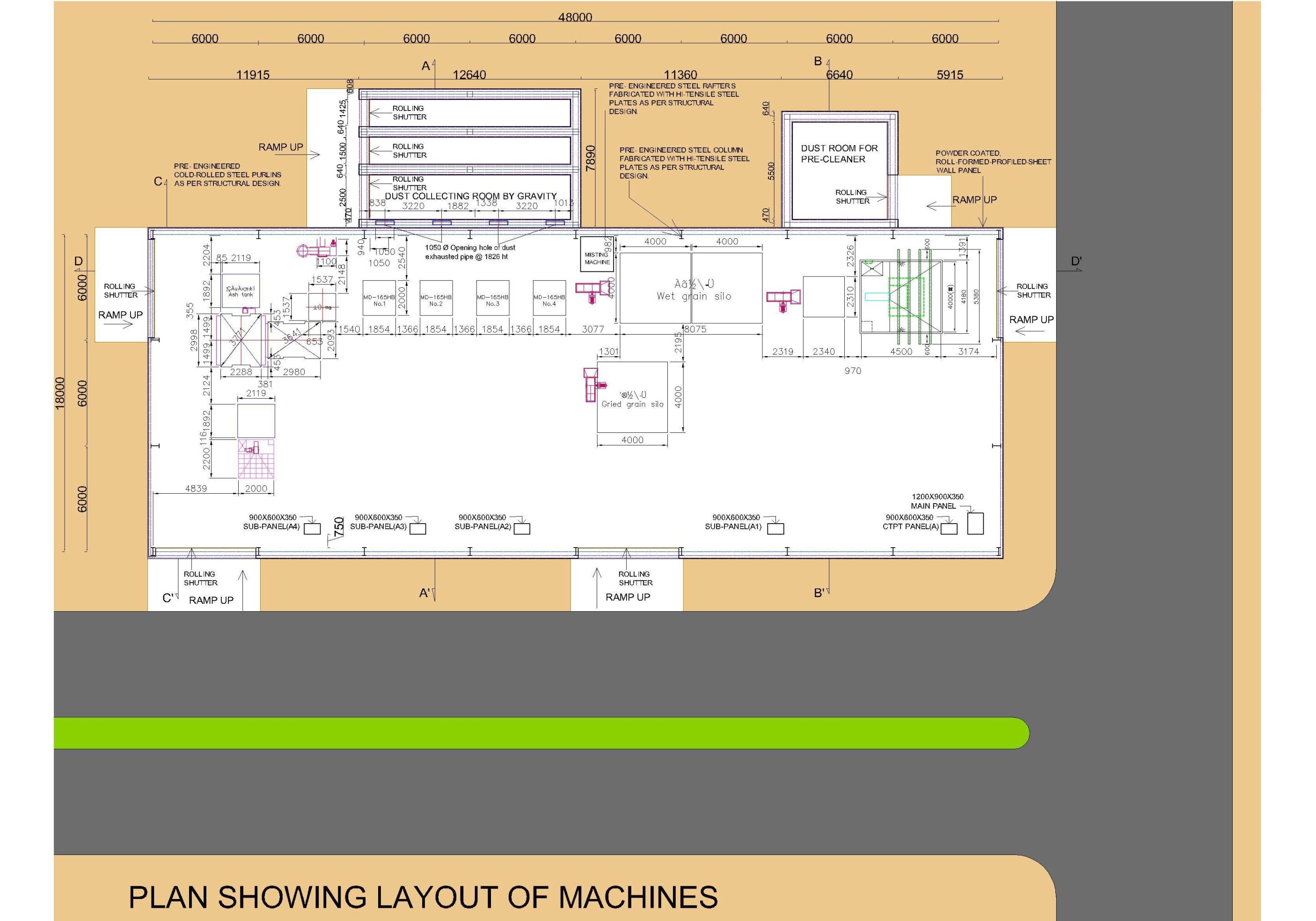

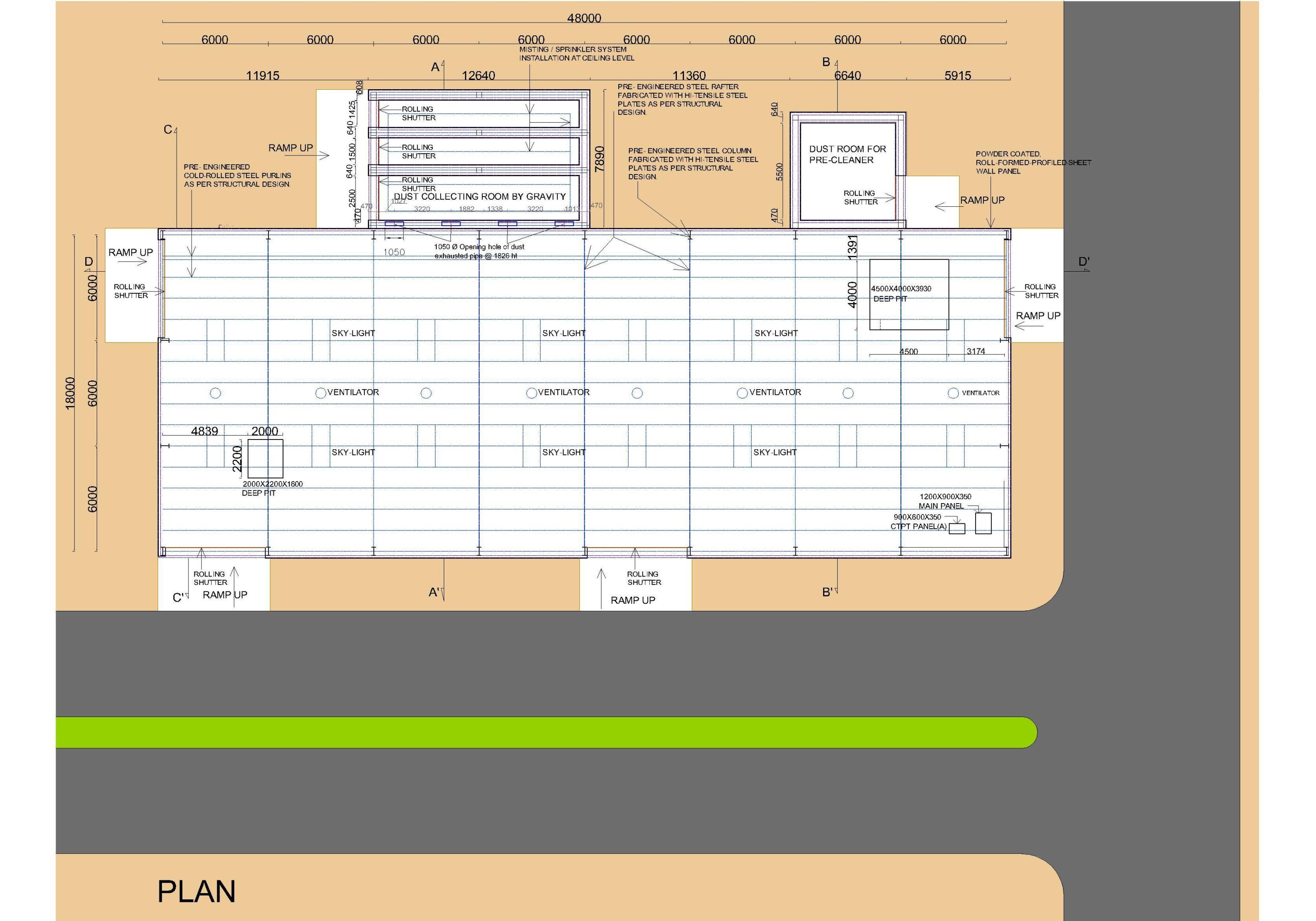

Drawings of smaller Maize Dryer.

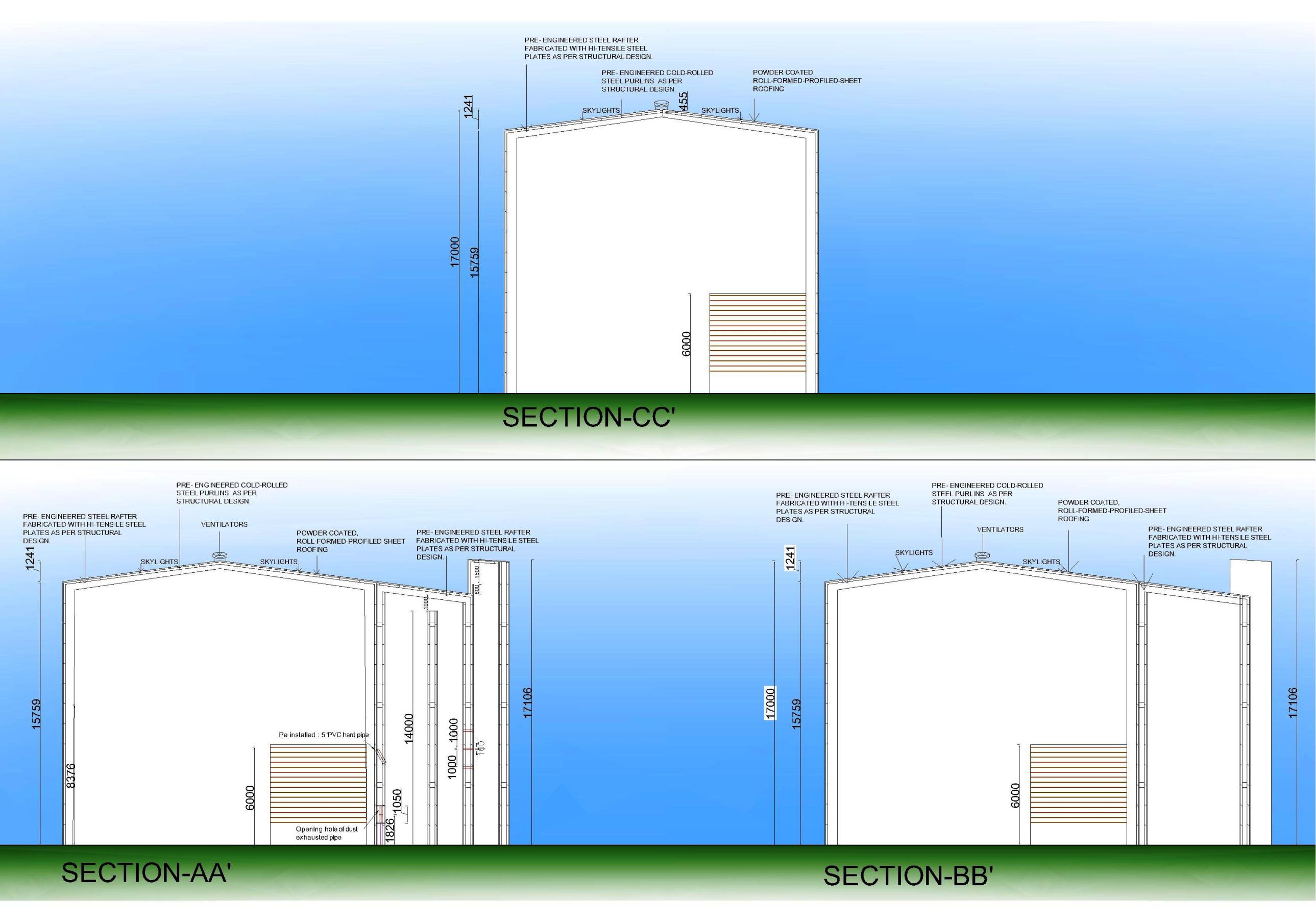

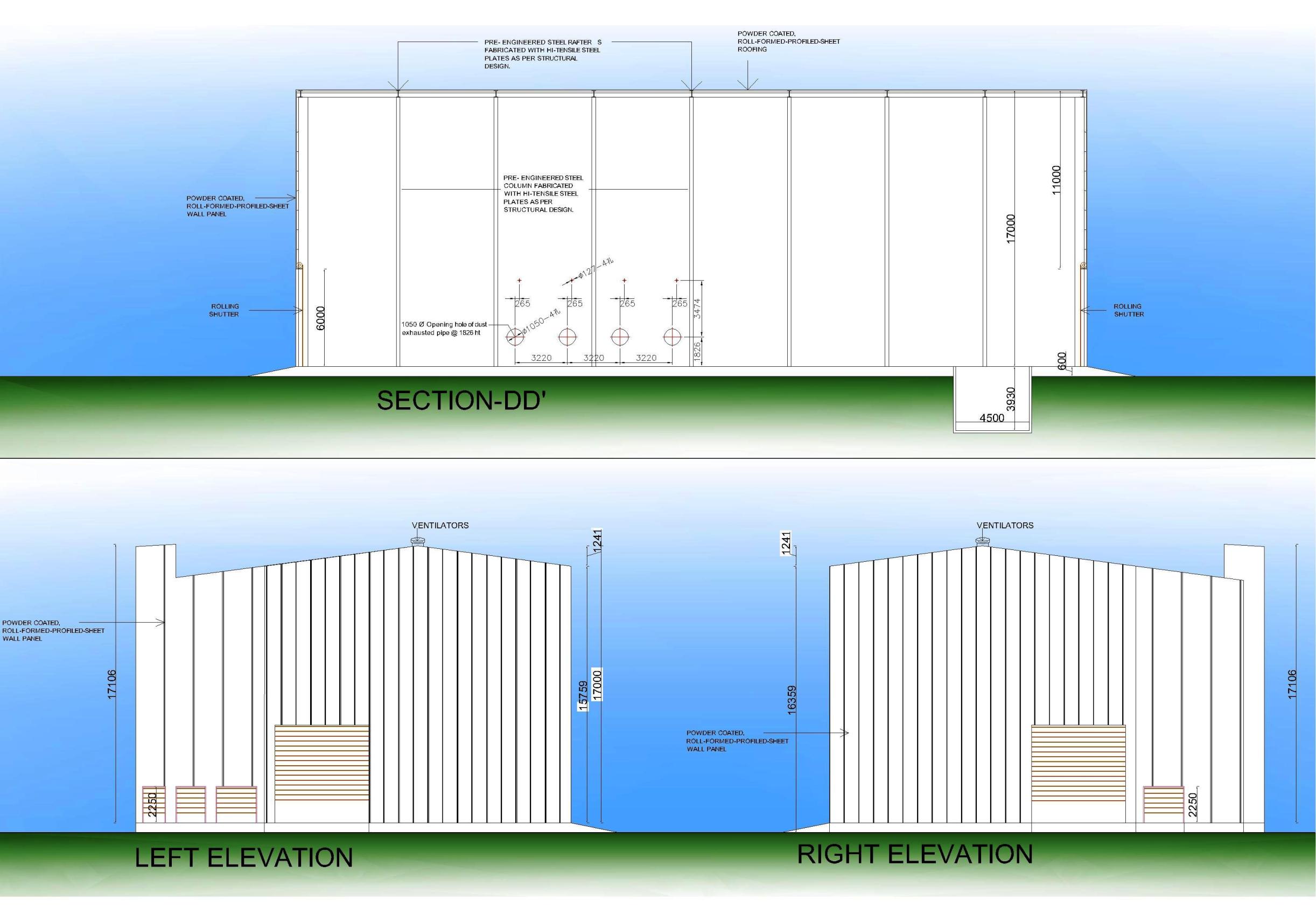

Drawings of bigger Maize Dryer.

All images courtesy of Sarbjit Bahga

> via The Pioneer & MODERN REGIONALISM: The architecture of Sarbjit Bahga