Submitted by WA Contents

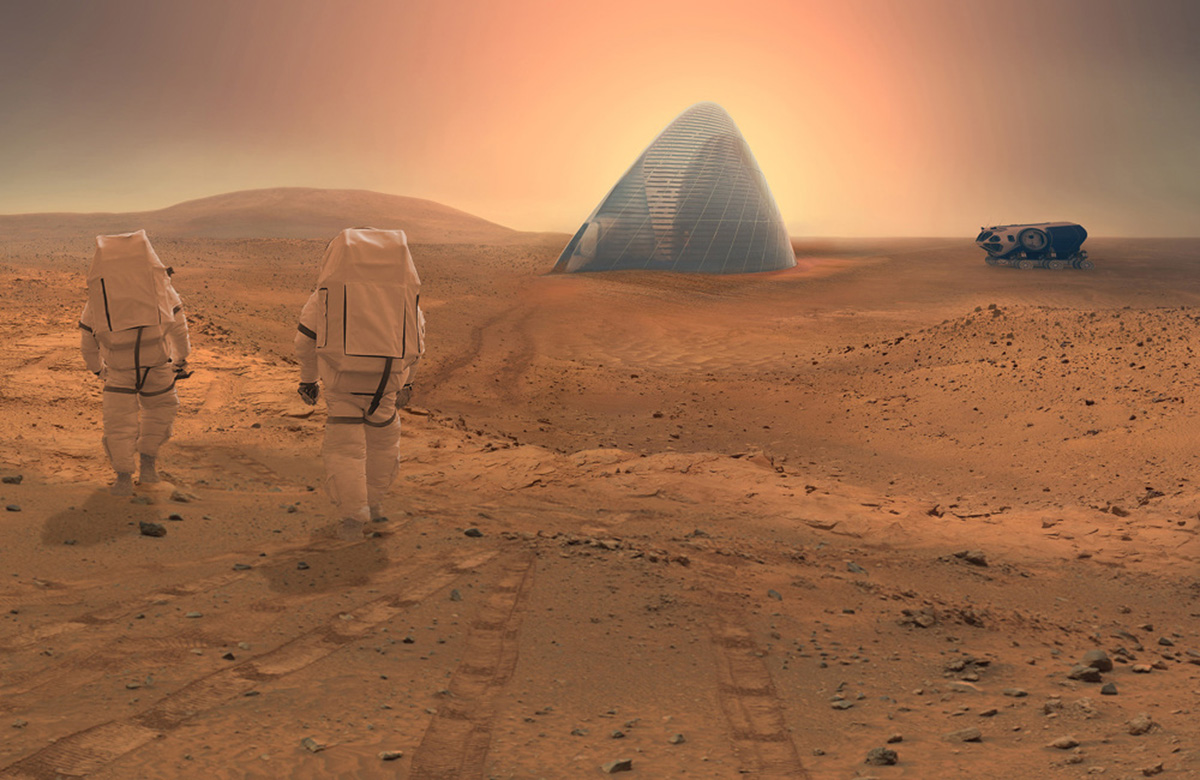

Mars Ice House uses inventive materials and 3D Printing techniques to build a new habitat on mars

United States Architecture News - Dec 24, 2015 - 12:54 8391 views

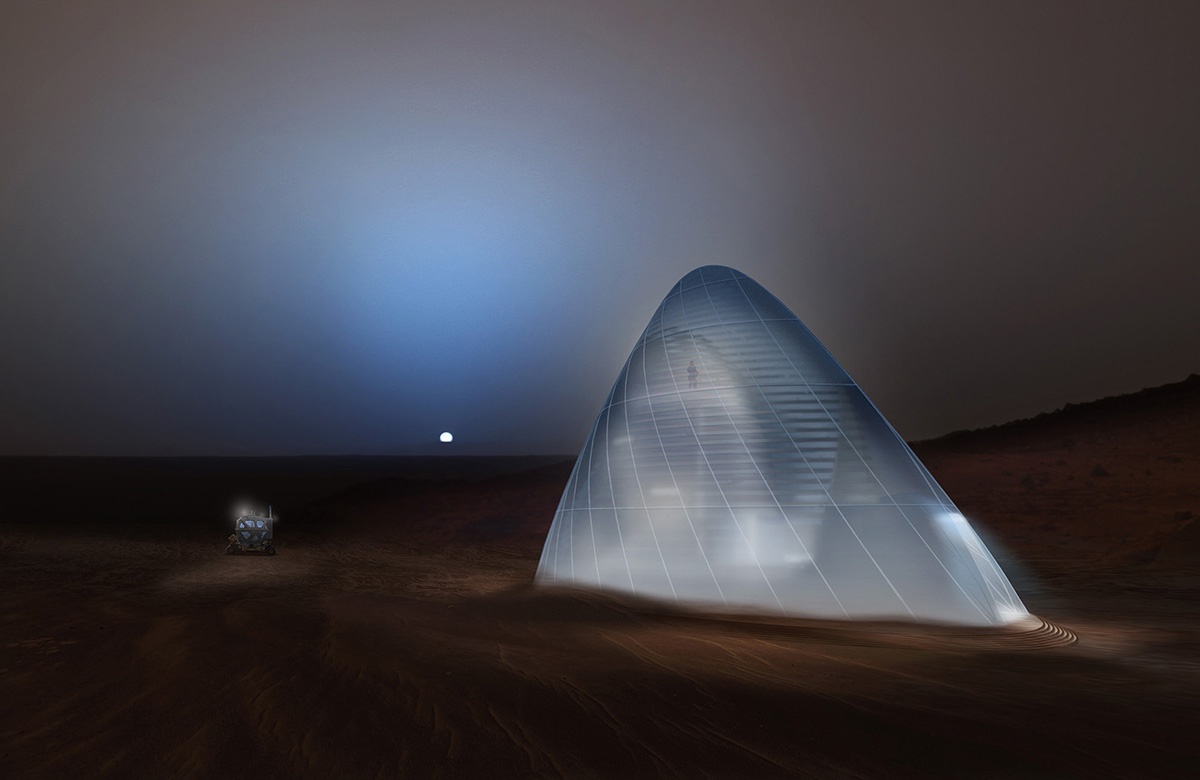

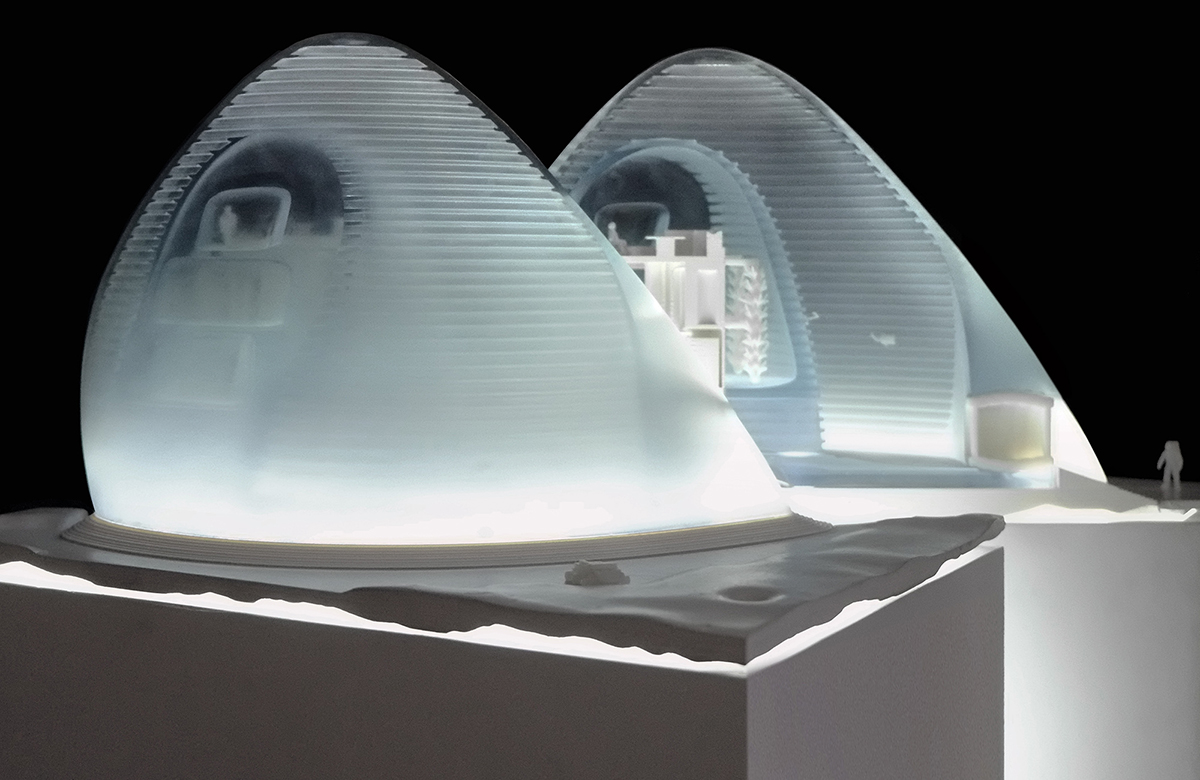

a transparent ETFE membrane keeps the 3d printed shells from sublimating into the Martian atmosphere

all images © Clouds AO and SEArch

''Mars Ice House'' is a new response to NASA's Centennial Challenge, Clouds Architecture Office (Clouds AO) teamed up with Space Exploration Architecture (SEArch) to create Mars Ice House, assisted by LERA Consulting Structural Engineers. SEArch and Clouds AO's first prize proposal, Ice House was awarded $25,000, among 30 other shortlisted practices in 3-D Printed Habitat Challenge.

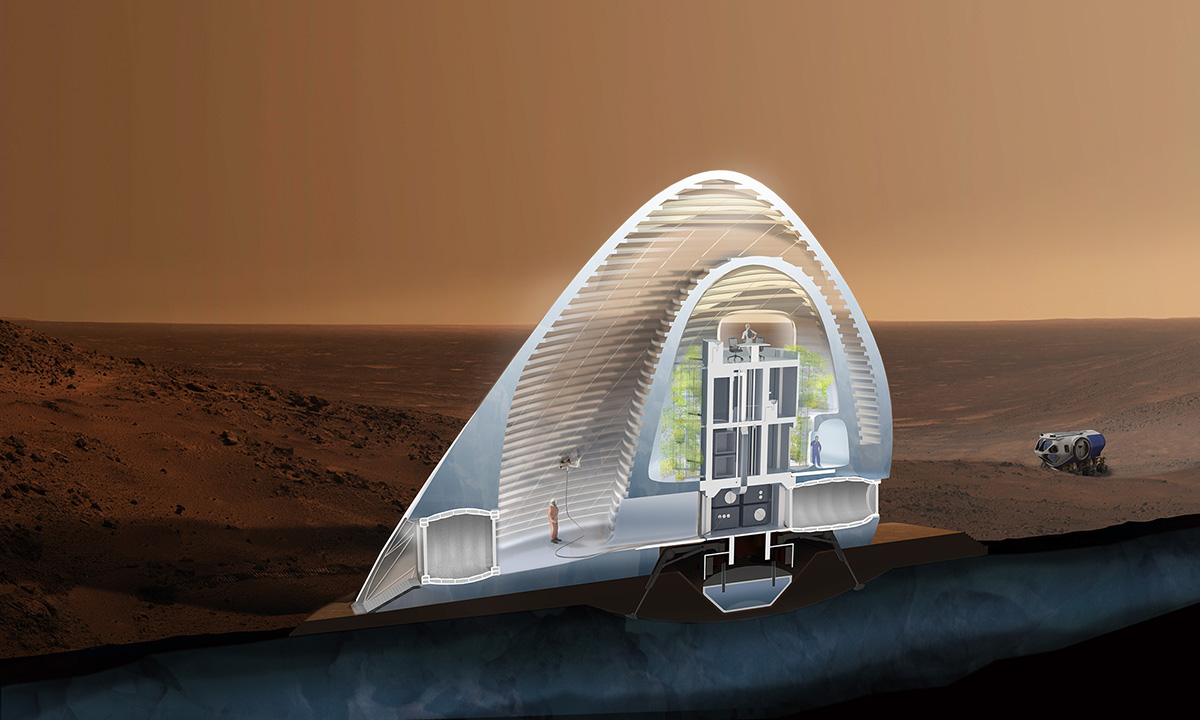

an integral spiral rib allows printing robots to navigate the interior surface of the ice shells

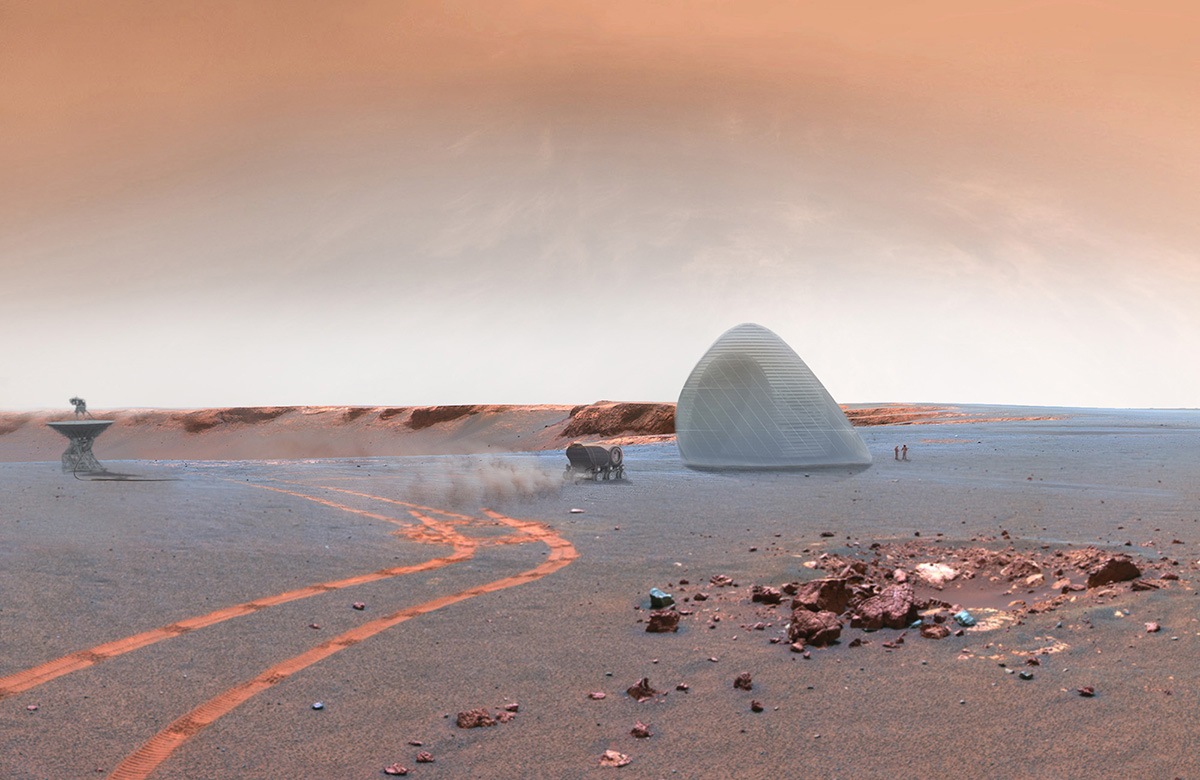

The studio explains that water is the basis for life. Our solar system is proving to be increasingly saturated with water. More than five million cubic kilometers of water ice have been identified on Mars, enough to cover the planet to a depth of thirty five meters. The Mars Ice House project taps into this vast supply of water ice to propose an autonomously 3d printed habitat for four explorers. The project has been awarded first place in NASA's Centennial Challenge Mars Habitat Competition, and is slated for a full scale prototype in the next phase.

Mars Ice House is 3d printed from translucent ice which shields the crew from radiation, and transforms into a glowing beacon in the Martian night

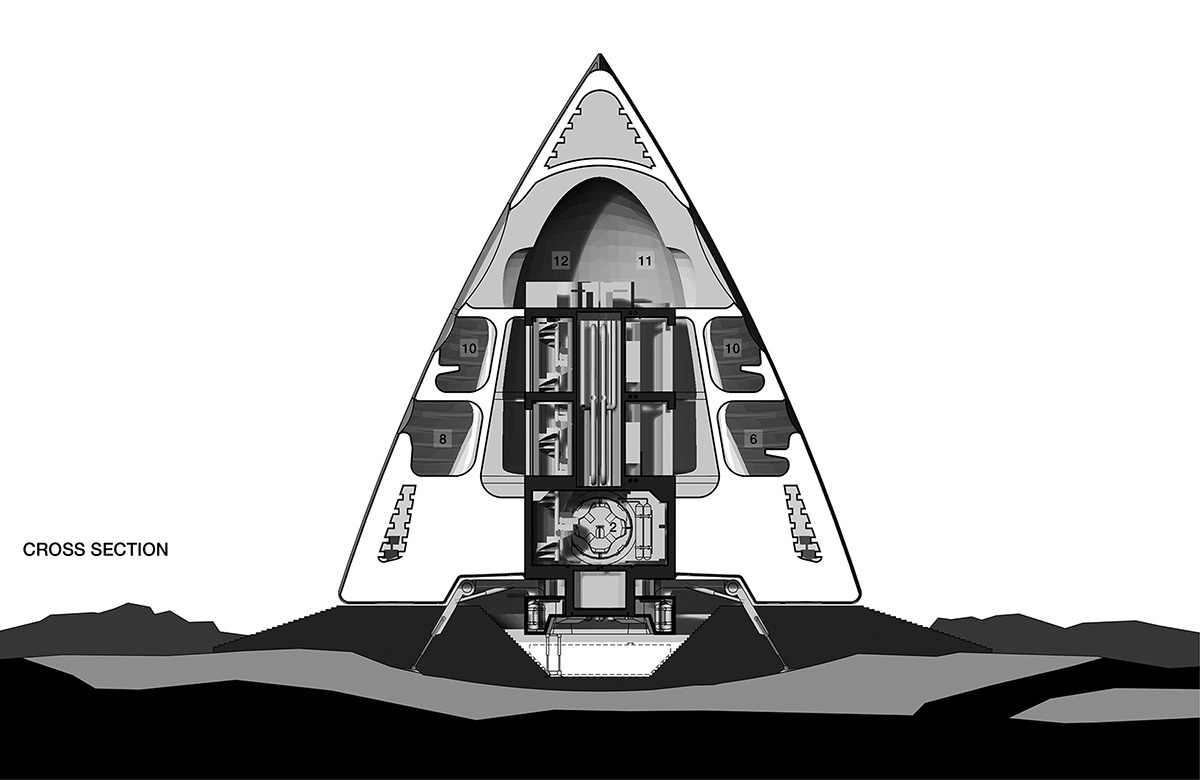

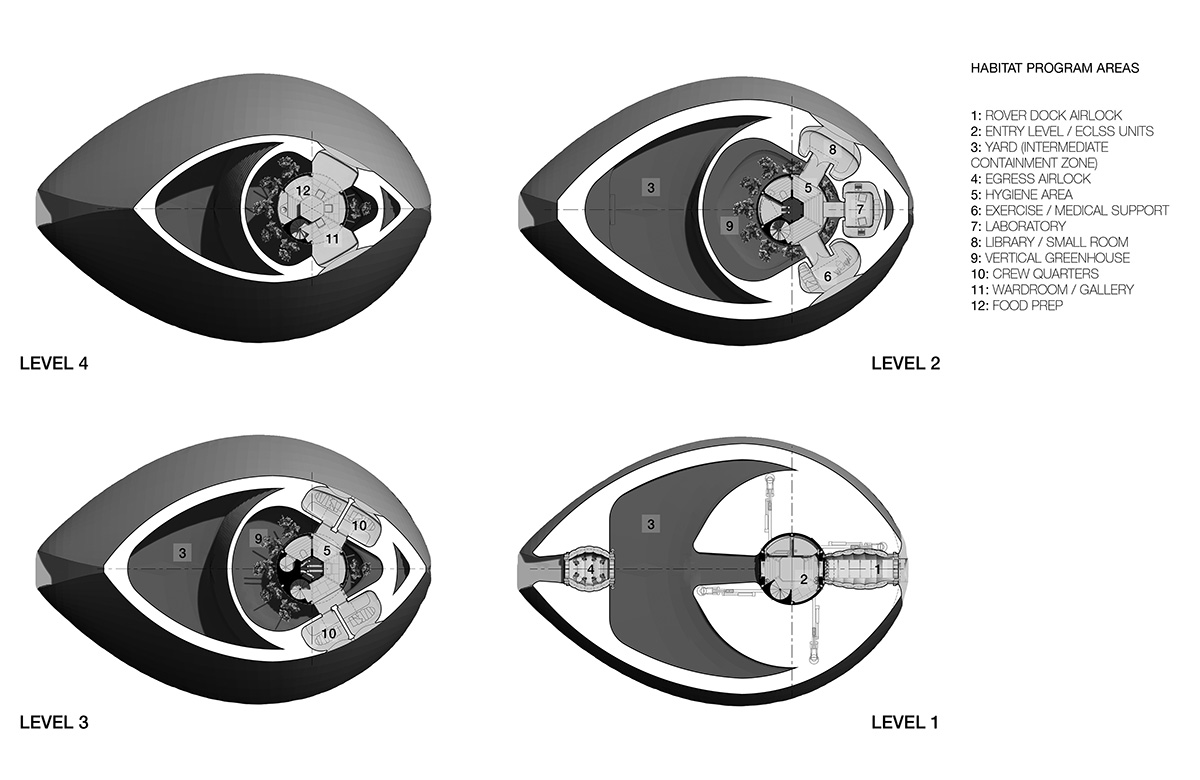

Formally, Mars Ice House is deliberate in redefining the prevailing diagram for off-planet habitats. The prevailing precedent has been inflated domes covered by a layer of regolith, which yields dark and claustrophobic habitats with potentially disastrous consequences for crew motivation and mental health. Mars Ice House redefines this typology by innovating a translucent fin shaped double shell structure contained within a transparent ETFE film. The form is driven by a humanist approach with crew comfort and well-being as key design factors.

A contemplative yard space between the two ice shells serves as a buffer to prevent forward contamination of the Martian environment

The 'yard' is an unprogrammed space between the inner habitat and outer shell. This area is not for any specific function (ie. sleeping, eating, working) but an undefined open space for contemplation, relaxation, exercise, game play or anything the crew decides to do. While not fully conditioned, this space is pressurized and can be inhabited with a simple oxygen mask. It also serves as a buffer space, absorbing leaks from the habitat environmental control and life support systems to minimize forward contamination of the Martian wilderness.

A double ice shell housing programmatic spaces within its layers is 3d printed around a lander habitat. A vertical greenhouse between the habitat and shell forms the crew’s yard

Why ice? Water ice is an effective radiation shield, diminishing both ultra-violet solar and galactic gamma rays to safe levels with only a 5cm thick shell. Ice is translucent allowing natural daylight to stream into the dwelling connecting inhabitants to circadian cycles necessary for maintaining healthy bio-rhythms.

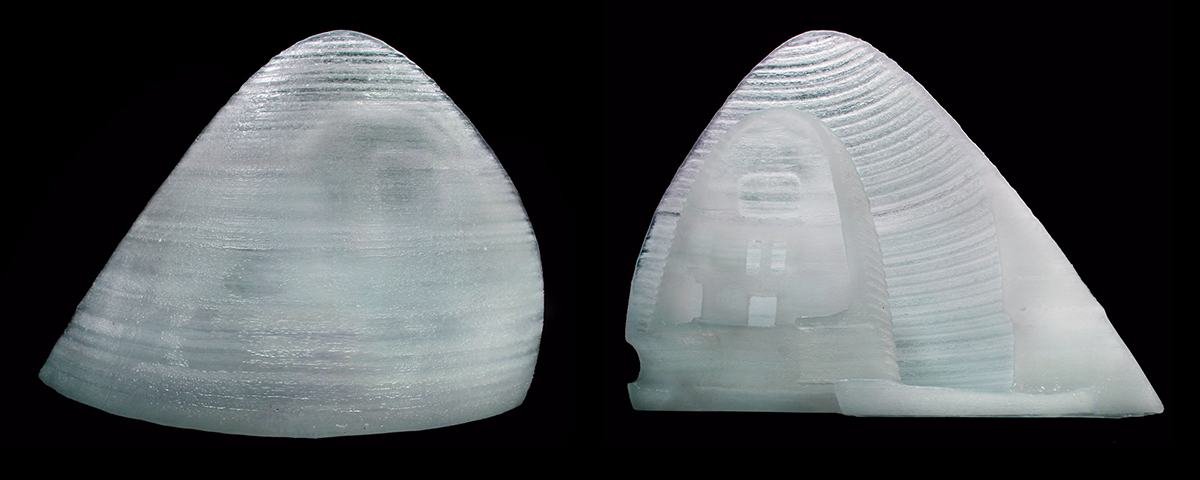

photographs of a 3d printed 1:75 scale model in resin

The translucency gradient of the ice shells can be modulated to achieve transparent windows allowing for views of the Martian landscape beyond, which has been proven to improve crew morale and psychological well being. Water ice is abundant in the northern latitudes and easily extracted as it's covered by only 30cm of loose regolith.

photographs of a 3d printed scale model of the ice shells fabricated by McGill University

It takes less energy to process and print with water, since the natural climatic and atmospheric conditions (below freezing with low humidity) allow us to take advantage of the physics of phase transition.

Project Facts

Type: Extra-planetary Habitat

Location: Northern Slopes, Alba Mons, Mars

Date: September 2015

Client: NASA / America Makes

Project Design Team:

Clouds Architecture Office (Clouds AO)

Ostap Rudakevych, Masayuki Sono, Yuko Sono

Space Exploration Architecture (SEArch)

Christina Ciardullo, Kelsey Lents, Jeffrey Montes, Michael Morris, Melodie Yashar

Consultants:

Jared W. G. Atkinson; Planetary Geophysics, MIT

Asmbld Construction Robotics: Petr Novikov, Yaz Khoury

Maria Banks PhD, Geology and Planetary Scientist, Planetary Sciences Institute

Kim Binstead PhD, Associate Professor, ICS Depatment, University of Hawaii

Casey J. Handmer PhD, Applied Mathematics, California Institute of Technology

Stefan Harsan Farr, Engineer and Software Architect

Jeffrey H. Hoffman PhD, Professor of Practice of Aerospace Engineery, MIT Department of Aeronautics and Astronautics

Norbert Koemle PhD, Geophysics, Austrian Academy of Sciences, Space Research Institute

Leslie E. Robertson Associates: Elias E. Matar, Edward Roberts, N. Brent Chancellor

Javier Roa, Orbital Mechanics/Aerospace Engineering, Technical University of Madrid and JPL Research Associate

Pavlo Rudakevych, Roboticist, Aerospace Engineer, Aviator

Markus Scheucher, Physics and Space Sciences, Karl Franzens University of Graz

Special Thanks to:

Dr. Ron Turner, ANSER Distinguished Analyst

Lawrence W. Townsend PhD, Chancellor's Professor of Nuclear Engineering, University of Tennessee

> via cloudsao.com