Plastic is a protean material that's extensively used and adaptable. Because of its affordability, inflexibility, and continuity, it has fully changed diligence and daily life. It's employed in various products, including electronics, medical outfits, consumer goods, and packaging. Still, serious environmental problems are associated with plastic's pervasive operation. Plastic trash threatens ecosystems and wildlife because it isn't biodegradable and can loiter in the terrain hundreds of times.

Plastic waste refers to any abandoned plastic material that's no longer demanded after reaching the end of its useful life. Plastic bottles, bags, packaging, and other consumer goods are exemplifications of objects that fall under this order. Given the frequency of plastic waste in the ecosystem, it poses a serious environmental hazard. Almost 7.2 billion plastic waste existed in nature from the beginning and needed 200 years to recycle at the current rate (9%). In discrepancy to organic accouterments, plastics take longer to biodegrade and rather scrap into lower pieces known as microplastics, which can jeopardize ecosystems and wildlife. Plastic is found from the bottom point of the ocean to the air. It is found in the human brain, lungs & hurt. It makes plastic waste one of the major problems in the world.

Like the world, Plastic waste has become an unavoidable problem in Bangladesh. Plastic clogging drains and waterways is a critical issue, especially in urban areas. like Dhaka, Chittagong, and Cox’s Bazar. Rivers such as the Buriganga, Jamuna, and Padma are heavily polluted with plastic waste. This pollution eventually flows into the Bay of Bengal, harming marine ecosystems and affecting the livelihoods of fishing communities. During heavy rains, blocked drainage systems lead to urban flooding, causing damage to infrastructure and health hazards. Plastic is an inseparable part of our life. Different uses of plastic benefit us. It is quite impossible to stop using plastic as there are no alternatives to it. Being non-biodegradable, it creates harm to the environment, animals, people, birds, and other creations. It is a global issue. Many marine creatures like blue whales die from it. Saint Martin and Cox’s Bazar Sea Beach are examples of it. Microplastics are found in our lungs & animal stomachs.

Chittagong is one of Bangladesh's largest cities and a major port, has profound environmental, economic, and social effects, one of the main hotspots of Bangladesh for plastic pollution. It frequently faces flooding during heavy rains, partly because plastic waste clogs the city's drainage systems. Chaktai, Rajakhali, and Tulatuli Canal are the major drainage systems in Chittagong. These work as vain of the Chittagong City. Stormwater passes through it & meets with Karnaphuli. However plastic waste Blocks canals and drains that prevent proper water flow, causing waterlogging that damages infrastructure, disrupts transportation, and poses health risks. As a coastal city, Chittagong contributes significantly to plastic waste entering the Bay of Bengal and nearby rivers, including the Karnaphuli River. Plastic waste in Karnaphuli and coastal waters breaks down into microplastics, which enter the food chain. This poses long-term risks to human health as microplastics accumulate in seafood consumed by local populations. Marine ecosystems are severely affected, with plastic waste harming fish, turtles, and other aquatic life. The fishing industry is impacted as microplastics and pollutants from plastics contaminate marine organisms, posing health risks to consumers and affecting the livelihoods of fishing communities. Tourist spots like Patenga Beach, Foy's Lake, and the nearby Hills Tracts suffer from plastic littering, which diminishes their natural beauty and ecological health.

Plastic is a revolutionary invention. It became a curse because of human habit. Because of a lack of public awareness, people through plastic waste to the environment without knowing the impact of it on nature, environment & livelihood. Growing public awareness is necessary to reduce the amount of new plastic waste. Plastic waste recycling is a way to solve the existing plastic waste problem. Though recycling is a convenient solution to plastic waste, it has a problem. For improper plastic waste recycling the quality of plastics is getting down. One plastic water bottle doesn’t return the same. It is recycled into the bucket. In this way, one time the plastic will not be eligible to use. So, it goes environment. If plastic sorting and recycling are done in the right procedure one water bottle will be from one water bottle by recycling. So, the pressure on virgin plastic will be reduced. Existing plastic will serve us.

For finding the solution to the problem, “Upcycling” is considered a concept. Upcycling is the creative process of transforming discarded or unused materials into products of higher value or quality. The goal of upcycling is to minimize waste by giving new life to items that might otherwise end up in landfills. This can involve repurposing old objects into decorative ones. Plastics are regularly used objects in our lives. By knowing its harmfulness, it is going to recycling. But it goes to downcycling. Proper process of recycling will ensure the reduction of downcycling. Creating the value of plastic upcycling will be held that makes the waste an asset. By using the philosophy, it is tried to upcycle public awareness to reduce plastic pollution & keep the workers motivated.

There are several ways by which different types of plastic waste can be recycled. By following a few specific ways plastic waste can be recycled very efficiently. Such as PET, HDPE, LDPE, and PP can be recycled. It should follow the process for recycling.

1. Firstly, they have to go through label removal.

2. Then it passes through a shredder where plastics are turned into small chips called plastic flakes.

3. Thirdly the flakes go through a hot wash where the plastic flakes are washed.

4. Then it goes through a sink float tank. Here plastics are floated & heavy unwanted material are sink.

5. Then, it goes through a rotatory dryer to dry.

6. Then an optical sorting machine differs plastics by color.

7. Finally, it goes to a granule-making machine and makes granules.

PVC & other types of plastic are not eligible for recycling. It is very harmful for the workers & environment for recycling. They have to go through wash & reuse. If it is not eligible for reuse for the same purpose it will go for upcycling. In this process, it will be reused for different purposes that grow the value of the waste from the previous. It is done fully by craftmanship, Not machinated/factory work.

Polystyrene/ PS needs different types of recycling systems. It is recycled by reverse chemicalization. By using acetone Polystyrene gets compact.

1. Firstly, it has to go through shedder,

2. Then it goes through a polystyrene compactor.

3. After that it will go through the grainer that will make the polystyrene chips.

After all of this, those plastics are not eligible for anything before they go for pyrolysis. Here 85% fuel, 5% black carbon & 10 percent purified CO2 will be found.

These elements are composed and synchronized in the production unit. By focusing on the production unit Public is invited willingly to the complex to grow public awareness. It is the major concern to grow public awareness without having any interruption on Production work.

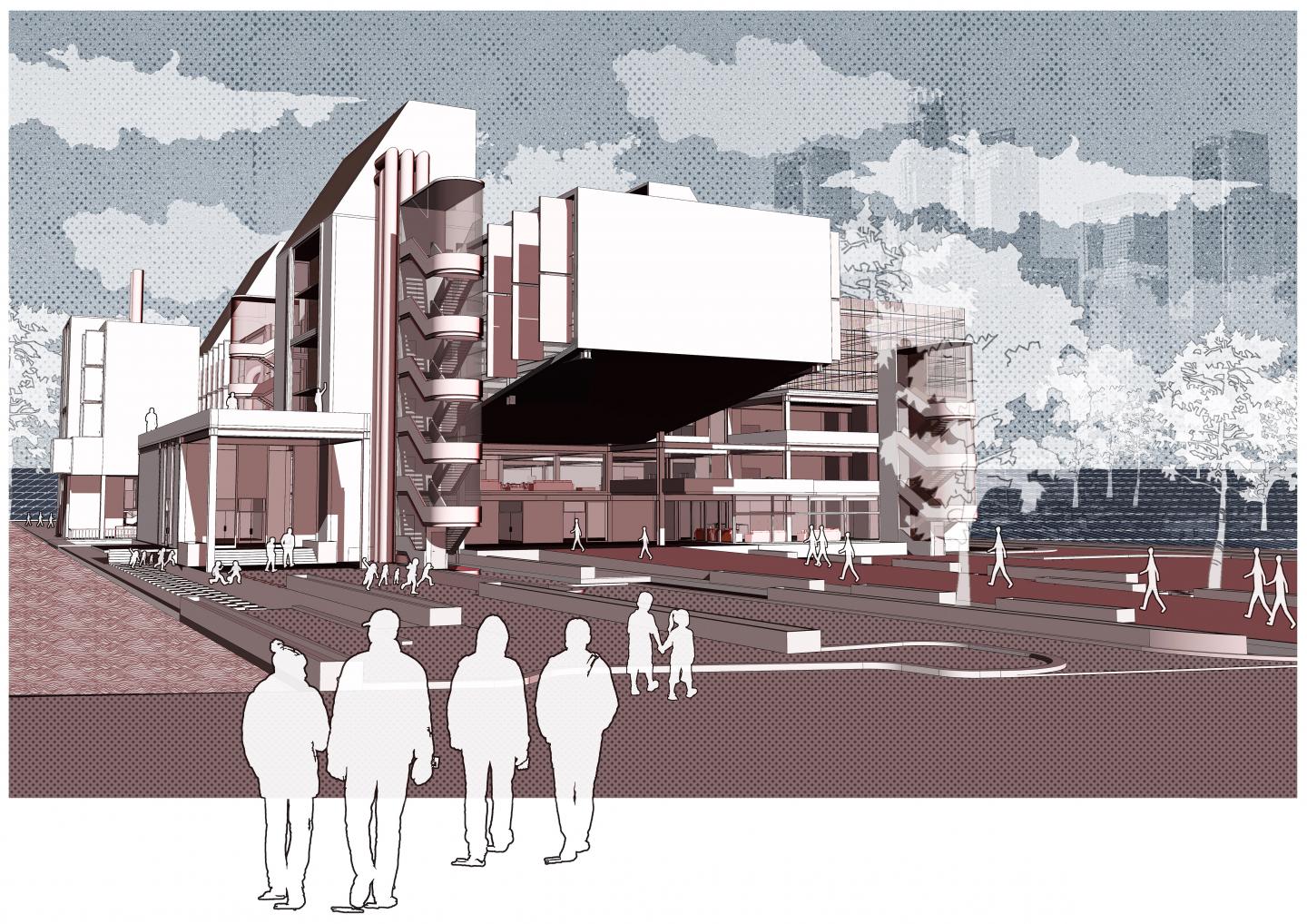

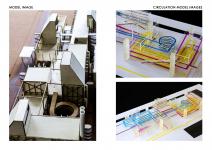

The whole complex is divided into two segments. They are the Industrial & Public segment. The industrial segment is divided into 3 sub-segments. They are the Admin Section, Workers Section, and Production Section. These three segments are fully connected. The public section is added here, without any physical connection. Here public section helps to explore people's outdoor recreational facilities. There is a facility for commercial activity where the public can see and explore the products that are produced in this complex & can buy them. The space work as a material bank cum marketplace. Here people also can sell plastic waste that they would collect or save. The complex also helps to explore the exhibition space where they have an opportunity to gain knowledge about the harm of plastic pollution. People can enjoy rooftop recreational activities from where they can see the factory works. A double helix public experience ramp helps to explore the loop. 3R library & VR zone provide the scope of gaining knowledge & virtual experience of the plastic problem & its solution. It gives a conclusion of the journey of the whole complex. The complex has two turfs that take a step to solve urban needs. The public facility helps to grow different types of indoor, semi-outdoor & outdoor workers’ facilities are provided here. Dining, indoor & outdoor paying space, Daycare, prayer hall, sleeping area, etc. are found here.

The production unit is maintained well-ventilated & lighting. The maximum depth of the wings is 50-55 ft. It is maintained to solve the ventilation & lighting needs of the production unit. It makes the work environment well. The interior space is in touch with the exterior space. Workers can take short breaks of 5 minutes and can enjoy outdoor refreshments. That will boost their energy & proved helpful to get productive work from them. As there is enough accessibility to escape, workers will reach to safe zone if there is any risk or hazard. A proper facility or fire hydrant is provided for safety.

To keep the environment cool different types of passive cooling technology are used in this complex. Windcatcher & Earth air tunnel is introduced here. By using an earth air tunnel temperature decreases by 10-12 degrees Celsius. It reduces energy consumption by 15% and saves electricity bills up to 10%. It is fully environment friendly. Windcatcher is very efficient for passive cooling though it is old. It can reduce the temperature inside the house by 8 to 12 °C (14 to 22 °F) in comparison to the outdoor temperature. It reduces almost 23% of energy consumption.

The project provides us with several benefits. Economic benefits are one of the important parts of this project. The price of recycled plastic is only 58% of virgin plastic. It provides 170% profit to the Plastic waste recycling sector. The project can produce 25 tons of plastics per day. Almost 1.25 million taka is saved every day by producing equivalent products.

The project can make a great contribution to reducing plastic waste in Chittagong. The total generated plastic waste in Chittagong is 249 tons/day of which 56% (139.4 tons/day) is not recycled. The factory recycled 25 tons/day (18%). Around 6 recycling complexes can recycle all plastic waste. This type of prototype factory can be installed in different areas in different cities according to needs. It is possible to reduce generating plastic waste & recycle existing plastic waste by establishing the prototype idea globally.

Plastic waste is one of the major problems in the world. But without plastic, it isn't easy to live nowadays. Its longevity & durability did us benefited. But it also proves harmful to us. Now we find plastic waste from the ocean to the sky. It has become a global problem that makes us sufferers. Recycling all the plastic is the best way to solve plastic waste. Public awareness is also essential for it. Different ways of plastic waste recycling are combined in this project that efficiently recycle all types of plastic. Architecture is played as an element to get people to explore & learn about the harm of plastic waste with their solution. The architecture is designed with consideration of well natural lighting & ventilation. Different types of indoor, semi-outdoor & outdoor facilities are considered for Workers. It will keep workers motivated for work & upcycled for everyday work. The complex will provide economic, social, and environmental benefits that will make us benefit. This idea will work as a prototype for the different areas according to their need. It will make the public aware of generating less plastic waste, recycling existing plastic, and reducing the use of virgin plastic.

2024

In the industrial project, it is very important to keep the work environment friendly. To keep the environment cool different types of passive cooling technology are used in this complex. Windcatcher & Earth air tunnel is introduced here. In Earth Air Tunnel technology, the inlet takes air from the outer side of the production unit & passes through underground. The pipe runs 1000 meters in a spiral formation from 4m below the ground surface. As the temperature of the earth is around 24 degrees Celsius constantly, the air gets cooler & gets into the building through the outlet. Indoor hot air goes out by the chimney by the use of the stack effect. By this there a vacuum of air is created. So that outer air comes inside to fill that vacuum. By using an earth air tunnel temperature decreases by 10-12 degrees Celsius. It reduces energy consumption by 15% and saves electricity bills up to 10%. It is fully environment friendly.

On the other hand, the windcatcher is very efficient for passive cooling though it is old. In this technology, a tower is used to catch the cool air & pass it through the production unit by the use of wind pressure. The technology can reduce the temperature inside the house by 8 to 12 °C (14 to 22 °F) in comparison to the outdoor temperature. It reduces almost 23% of energy consumption.

According to the need, the fire stair is placed so that people from anywhere in the building can rescued & save their lives. Enough water resources are provided to reduce the hazard of fire. A fire hydrant facility is also provided in the complex for fire safety.

An ETP (Effluent Treatment Plant) is installed in this factory so that the used water in this complex can be refined and used multiple times. It can refine 22 KLD water can per day.

Studio Mentors: Dr. Sajal Chowdhury (Assistant Professor, CUET), Rezuana Islam (Assistant Professor, CUET)

Supervisor: Amit Imtiaz (Assistant Professor, CUET)

Favorited 1 times