【 Project Summary 】

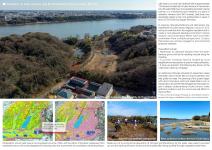

This residence faces Lake Sanaru Park. A few years ago, Lake Sanaru had one of the worst water quality rankings in Japan. Since then, various initiatives aimed at improving water quality and preserving biodiversity have been undertaken by governmental bodies, universities, local organisations, and neighbourhood associations.

Respecting these efforts, the design of this house sought to contribute to the lake’s ecological restoration. We focused on biochar, a charcoal material made by carbonising unused branches of mandarin orange trees—a local, underutilised biomass resource. Known for its high water purification and soil improvement capabilities, biochar became the key material in our approach. In collaboration with a paving block manufacturer, we developed biochar blocks inlaid with this carbonised mandarin wood. These blocks were used for both exterior and interior finishes, utilising approximately 21 tons of biochar in total. On the exterior, the material provides high thermal insulation; on the interior, it helps regulate humidity and purify indoor air, contributing to a balanced thermal environment.

Additionally, the exterior walls promote the purification of rainwater, which then flows across a copper roof—also known for its purifying effects—before being directed to the landscaped areas. There, the water infiltrates through biochar-enriched soil, undergoing further purification before seeping into the groundwater and eventually feeding the nearby wetland. In this way, the architecture and site function as an ecological rainwater filtration system, connecting visually and ecologically to the environment of Lake Sanaru Park. By positioning biochar as a nexus between local woody waste and water resource circulation, this project represents a regenerative architectural practice that leverages biomass toward a carbon-neutral future.

【 Regenerative Architecture Contributing to Water Purification in Lake Sanaru 】

Focusing on the biochar’s water purification and soil enhancement functions, this project repurposes unused local resources—namely, mandarin trees—as a regenerative material. The biochar is applied not only in architectural finishes but also in civil works, becoming part of a broader ecological infrastructure that actively participates in improving the environmental quality of the nearby wetlands, spring-fed streams, and forest—all part of the Lake Sanaru Park ecosystem.

This requires a fundamental shift in perspective: design must move beyond being “for humans” alone, and embrace a more inclusive and long-term vision—design for nature, and for the multitude of living beings we coexist with. Through the lens of regenerative architecture, we sought to uncover a new relationship between the built environment and the ecological systems that surround and sustain it.

【 ZEH environmental monitoring 】

This residence was designed as a Zero Energy House (ZEH), integrating both passive and active environmental strategies to achieve high performance. The thermal envelope is enhanced through on-site sprayed urethane insulation (UA value 0.52 W/㎡·K), while solar heat is absorbed directly by a stone-finished engawa to support thermal mass. The entire 34-meter frontage of the house is equipped with triple-glazed wooden sash windows that open fully, allowing for natural ventilation. Underfloor air distribution ensures thermal comfort, and a passive heat-exchange ventilation system reduces mechanical loads. A rooftop photovoltaic system, combined with battery storage and reverse power flow capabilities, allows the home to be self-sufficient during emergencies.

As a result, the house operates with net-zero or even negative primary energy consumption, achieving a 56% reduction in residential CO₂ emissions—well above the national target of 40%.

【 The Potential of Biochar as a Carbon Stock 】

In recent years, the agricultural use of biochar has attracted attention as a simple and effective method for carbon sequestration in soil, contributing to CO₂ reduction. However, in the field of architecture, its application remains largely in the experimental and research stage. Biochar is produced by carbonising wood that has absorbed atmospheric CO₂ through photosynthesis. This process locks the carbon into a stable form, effectively sequestering it rather than allowing it to return to the atmosphere. In this sense, biochar blocks function as a form of negative emission technology, transforming CO₂—commonly seen as a cause of global warming—into a carbon resource that can be captured, reused, and repurposed in architectural materials.

【 Carbon Storage Comparison through Woody Biomass Utilisation 】

To better understand the potential of biochar architecture, we compared the carbon storage capacity of our project to that of a hypothetical wooden house of the same scale. A fully timber-framed version of this house would use approximately 61 tons of wood, whereas our project incorporated 21 tons of biochar.

However, when wood is carbonised into biochar, the carbon content ratio increases from 0.50 to 0.77, and even after 100 years, approximately 0.89 of the carbon remains stable. As a result, despite being used primarily in finishing materials (not as structure), the biochar house demonstrated 1.4 times the carbon storage of a wooden house, and approximately 5.4 times that of an RC or S-structure. This suggests that biochar housing utilising unused woody biomass has even greater potential for CO₂ reduction. Moreover, it presents a new carbon-neutral alternative for RC and steel-frame construction, expanding the possibilities of regenerative material strategies in architecture.

2022

2024

【 Client 】

Client / Hiroyuki Kumagai

Primary Use / Residence

Family Structure / Couple 2 children

Location / Chuo-ku, Hamamatsu-shi, Shizuoka,Japan

【 Structure & Construction 】-

Main structure: Steel construction

Foundation:Pile foundation

【 Scale 】

Number of floors:2 floors above ground

Eaves height:7,611mm

Highest height:7,985mm

Site area:595.99m2

Building area:237.01m2 (building-to-land ratio 39.77%, 40% allowed)

Total floor area:338.72m2 (floor area ratio 51.60%, 60% allowed)

1st floor:236.28m2

2nd floor:102.44m2

【 Process 】

Design period:September 2020 - December 2022

Construction period:December 2022 - February 2024

【 Design 】

Design:ASEI Architects Inc.

Structure:Enshu Structural Design

Facilities & Electricity:ArtSogo Sekkei Inc.

Construction:Kano Komuten Inc.