CONCEPT:

The Kirloskar Group is one of Indias premier engineering groups with over 116 years of manufacturing pumps and a global presence in more than 70 countries. Their intention in coming up with this facility was to get all their people working under one roof in a facility that was contemporary as well as functionally upgraded. KBLs interest in a sustainable building was a huge impetus to the success of the project.

The region’s intense summer demanded a design that would harness the bright light and block heat ingress. Moreover the idea of water as a concept connected subtly but interestingly with both KBLs profile as water-pump manufacturers as well as the thought of providing sunshades in the shape of water droplets.

DESIGN:

The region’s intense summer demanded a design that would harness the bright light and block heat ingress. Quirky skylights punctuate the ceiling, filling the building with gentle light. The buildings most iconic feature is the collection of large umbrella-like shading structures on the western facade. These cut out the harshness of the sun while bringing soft light into the offices. Multiple miniature windows to the East provide cross-lighting while expansive glazing to the North provide ventilation and even more light. The landscape design thoughtfully utilizes planting that have very low moisture requirements.

High water efficient CP & Sanitary fittings have been used in all washrooms and 100% recycling of waste water while all DG sets are set to run on BioDiesel.

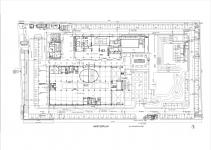

On a master plan level the Campus of 4.85 acres houses a corporate office block of a Lakh square feet and a clubhouse of about 25,000 square feet. It also houses other utility buildings like the energy block and the security blocks. The site has two access roads with the main approach along the West side.

The Corporate block is a G+3 structure. The design has been conceived in a stepped form using a series of horizontal planes. The first plane is a 10m cantilevered entrance canopy which doubles up as a drop-off zone as the main visitors access. It also gives a direct access to a 180 seater auditorium at the first floor. The entrance gives glimpses of the main reception area and the heritage room which displays the rich tradition and history of the Kirloskar Group.

The meeting rooms, auditorium, conference rooms and the departments located at the ground floor encourage high visitor movement. The upper floors are relatively laid back.

The main building is divided into the south and north wings. A double height atrium space presents the building with its rich green volume. This space is extensively landscaped with connecting pathways and bridges at upper floors. The auditorium spans between the ground and first floor given access from both. The second floor gets a wide green terrace with flowering trees and shrubs overlooking the main entrance canopy.

The third floor is contains the management’s cabins and facilities. The CMD and Board room open out into the third floor terrace space which again is rendered green.

MATERIALS:

Regional building material, materials with high recycle content including re-rolled steel, PPC cement for non structural work and fly-ash bricks were used extensively in construction. The innovative fabric cover used as a shading device for the building effectively blocks out the majority of the heat while allowing light to filter through.

The structure is an RCC framed structure using the Post tensioning process to achieve bigger column-free spans. The walls are in fly ash bricks which have high post industrial recycle content. The glazing used is a combination of openable and fixed panels. The glazing types used is spider system for the reception and heritage areas and channel systems for the workstation areas. Openable glass panels are also made in structural glazing systems for meeting rooms and cabins. The glass used is an energy efficient heat resistant glass in double glazed systems.

Flooring ranges between granite floors for reception, Jaisalmer and pebbles for corridors, vitrified flooring for workstation areas and carpets for meeting rooms. The third level has marble floors for common spaces, carpets for conference rooms and FSC certified wood floors for CMD and Director cabins. The terraces have decking wood outside cabins and china mosaic for the balance area.

Bridges are made in structural steel with wood floors. Railing and handrails use G.I. wires and mild steel. Skylights are made in toughened laminated glasses for safety.

External finishes use textures paint for walls and aluminum louvers for service areas and staircases. Maximum glazing happens on the east, north and south side. The south side glazing is shaded by three storied fabric-covered structures. The fabric is a semi-transparent, washable material, transparency enough to display the structure behind.

The landscape is simple yet elegant. The parking areas use grass pavers with their own textures. The vehicular access uses Concrete Paver blocks. The entrance drop off uses dressed locally available basalt stone in a crazy pattern giving respite from the linearity of the building design. The entrance steps and pedestrian ramp are in granite. The amphitheatre uses lawn surfaces for seating.

2007

2009

Land Area: 4.85 acres

Built Up Area: 1,30,000 sq.ft built up area

Cost: Rs. 42.00 Crores / US$ 9.25 Million

Scope of Services: Master Planning, Architectural, Interiors, Structural, MEP & Landscape Coordination.

The building uses an innovative and efficient state of art Water based VRV (variable refrigerant volume) system for Air conditioning of the facility. The cooling towers are located in the service area of the plot. The server room is supplemented by Precision air conditioning systems for 24x7 operations.

Electrical power is backed up by three diesel generators out of which two main diesel generators are bio-diesel driven. Of the total power consumption, nearly 2.5% power is generated by using Solar PV Modules. The building is equipped with state of the art Safety-Security System and Intelligent Building Management System for central monitoring of all the services. Fire suppression systems have been used with a fire water tank located below the amphitheatre. The treated water has been used for Landscape irrigation.

V. Naresh Narasimhan, Kumar Ravindra, Vinayak Thorat.