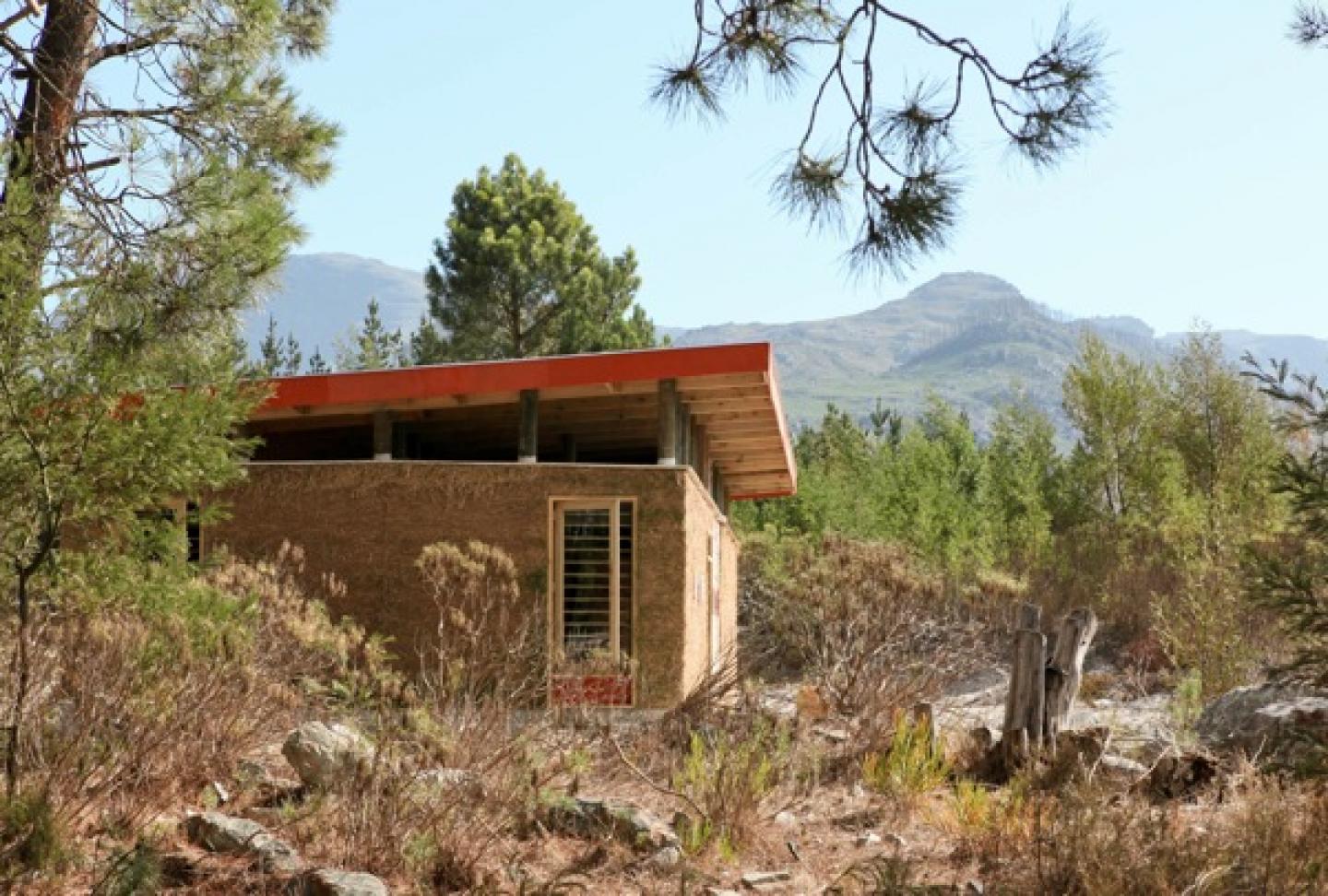

The basic idea was to incorporate the traditional building materials seen in the typical South African houses built by the Zulu and Xhosa. In the townships, the slums outside larger cities, most houses are not built in traditional manner, but rather with cheap corrugated sheet metal. In contrast, many clay houses in hte countryside still sport a straw roof. The local climate and environmental protection was especially important to us and we decided to use traditional and natural materials such as clay, straw, and wood in combination with valuable recycled materials. In just this way, we brought tradition and innovation together under one roof. The building is meant to be a home for up to four volunteer workers during their extended stay at the Village of Hope. We managed to build the homely unit with large open rooms that flow harmoniously into eachother.

2010

2011

Windows:

All of the windows were built with locally grown Pine and entirely by the students and a few local workers. Due to the high crime rate in the Township, all opening elements (windows and doors) must be built to prevent intrusion. A steel screen did not seem like the right way to go about it, because at the end of the day, we are building a home, not a prison. We decided to use branches from an especially tough tree, the local „black wattle“, and built them into the frames of the windows. That way, we were able to avoid the „barred window“ effect.

Recycling was also a main aspect to the design of the house. A local appliance store gave us eight washing machine doors, which we integrated as windows into the straw walls. The decorative elements are definately no longer recognizable as used houshold apppliances.

Structure:

As opposed to the planed and calculated square columns, we arrived to find out we should actually use round columns from Pine wood. In South Africa, it was not possible to find wood in the right shape and/or quality, therefor we had no other choice but to select the round tree trunks. The local engineer found our planned number and size of column quite excessive and overbuilt. Although probably true, at least we got something else out of it; a light-hearted smile from south african laborers every once in a while. Luckily, one of the students was a trained carpenter, who tought the others in the framework group and professionally finished the round columns. The 36 columns were each planted one meter into the concrete foundation and safely secured with additional nails to prevent them from rising up.

Straw-clay Walls (Casing):

One very important question drew many curious onlookers to Grabouw: „How can you turn 250 straw bales and 12 cubic meters of clay into a house?“ The answer: „Many motivated students that work day in and day out!“ Again and again: loosen the straw, soak it with the clay water, mix it, let it seep for twelve hours, build a migrating casing, compact it in the casing, move the casing, keep compacting, compacting compacting. It is extremely strenuous work, but after four weeks, the walls are finished. The straw-clay walls transfer heat very poorly, which means, the insulation of the house is very high, which is essential during the extremely hot summers and relatively cold winters (even in South Africa, it can get down to freezing!).

Low costs ( we paid approximately €1000 for all of the walls), the high ecological value, and the simple methods of construction were all deciding factors that convinced us to build in such a way.

ukuqala:

Jan Baisch

Johannes Brückner

Torsten Buck

Philipp Burst

Fred Ernst

Franziska Friedrich

Sarah Ischka

Roman Kaupp

Simon Köppl

Felix Leitz

Veronique Pavelec

Hristina Safronova

Lea Uhrner

Heiner Wolsberger

Janosch Welzien

Ulrich Kneifl

Meike Schlienz

Marianne Trauten

Ines Wulfert

Matthias Vogel

Ulrike Perlmann

Gerhard Perlmann

Leslie Koch

Favorited 1 times