Since the beginning of the current century, the media talk has revolved around two basic issues: energy and pollution, and how to find solutions to reduce the waste of the electrical energy production process, and reduce the high cost of energy production.

The other issue is pollution and research into the main causes, whether factory waste or household waste. It causes many problems, as it is one of the main causes of pollution. In light of this, the municipality of Baghdad still deals with the waste using primitive methods, which is the collection of waste in certain places and it is burned randomly - without sorting it - that method is considered polluting the environment, as random burning results in the rise of fumes containing chemicals that may be toxic that cause injury to some types of Cancers

Hence, we found the necessity to search for new, atypical solutions that serve the community and serve as a starting point for the direction of the spread of this type of projects in Iraq and the Arab world, as the Arab region is almost devoid of this type of projects - with the exception of the United Arab Emirates - which has worked to build an integrated station. To sort waste, treat it and generate energy through it.

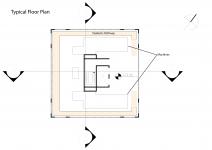

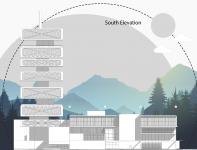

The Concept is Creating a new image for industrial buildings by converting the arrangement of production operations from horizontal to vertical.

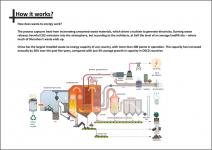

Most of the waste-to-energy plants burn solid waste coming from the municipality, and some burn industrial waste or toxic waste. In terms of volume, these plants burn 80 to 90 percent of waste. Sometimes ash residues are used for certain purposes as a raw material for making cylindrical bricks or for road construction. In addition, minerals that can be burned are collected from the bottom of the furnace and sold to foundries.

This project aims to design a waste-to-energy conversion plant to get rid of waste and produce electrical energy 600 MW/H in inexpensive and environmentally friendly ways.

2020

2021

Around the world, waste generation rates are rising due to rapid population growth and urbanization. Poorly managed waste negatively impacts the entire planet. Waste to-energy (WTE) plants offer a profitable and environmentally friendly way of properly managing waste.

Integrating a steam reheat system into a WTE plant is one of the best ways to increase overall plant performance. In a Siemens reheat turbine package, live steam is fed through a high-pressure (HP) turbine, returned to the steam generator to increase the steam temperature, then routed through a low-pressure (LP) turbine.

Raising the temperature of the steam passing from the HP turbine section to the LP section generates greater output suing the same amount of fuel. Siemens offers geared single- and double-casing reheat solutions Turbines for the WTE industry must not only meet the specifications governing steam extraction and control, but also operate highly efficiently. With the support of Siemens and the company’s deep understanding of processes and thermodynamic specifications, plant operators are able to meet and master this complex challenge. With more than 100 years of steam turbine experienced under its belt, Siemens offers tailor-made products that can be smoothly integrated into existing system environments – thanks to the high flexible operating modes of these turbines and optimized interfacing between the boiler and steam turbine. Siemens makes the solution fit the environment, not the other way around.

Flue Gas Treatments works to purify the product of the incineration process from fumes, as the fumes pass through several stages of filtration until they are harmless to the environment.

SUPERVISED BY:

DR. AMER ALJOKHADAR

Petra University

Graduation Project