This project investigates the architectural application of the hygroscopic behavior of wood. The final design is a kinetic façade system that passively responds to changes in the environmental relative humidity (RH). This system would open to provide shade when the RH decreases and close to allow more sunlight when the RH increases.

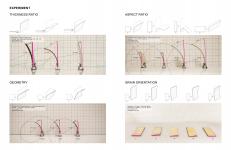

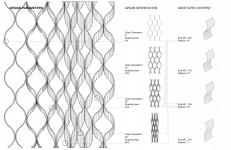

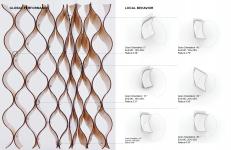

The hygroscopic behavior of wood is a property that leads to dimensional changes when wood absorbs moisture from the environment or loses its own moisture content. The first challenge of this project is to study the material behavior. After researching wood types and the mechanism of wood bilayer actuators, a humidity chamber was built to control the RH and explore the dimensional change of wood bilayers in relation to the moisture condition. At the micro-scale, four sets of experiments were conducted to help understand the hygroscopic behavior. The examined parameters included: aspect ratio, thickness ratio, geometry, and grain orientation. These experiments helped to decide on the implementation of the final design.

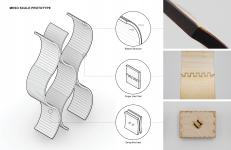

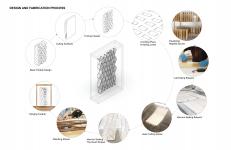

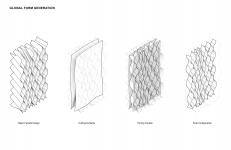

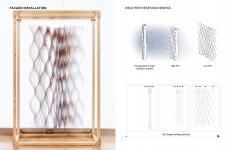

The design process is a combination of a bottom-up material investigation and a top-down design proposal. The material system is composed of maple-spruce bilayers connected through finger joints and elastic string knots. Digital simulations were conducted to predict the curvature conditions and global performance of aggregated local behaviors. The Timoshenko Equation, which was originally used to describe the curvature of bi-metal in regards to heat, was adopted to simulate the curvature of bi-layer wood due to RH fluctuation. Since wood is a natural material, its non-uniform characteristic would lead to uneven dimensional changes. Due to this, the major parameters needed to generate the basic geometry of the façade, while optimizing the shape-shifting performance with less uncertainty, were narrowed down to: grain orientation and moisture content. Finally, the proposed configuration was trimmed by two surfaces to achieve a more dynamic form.

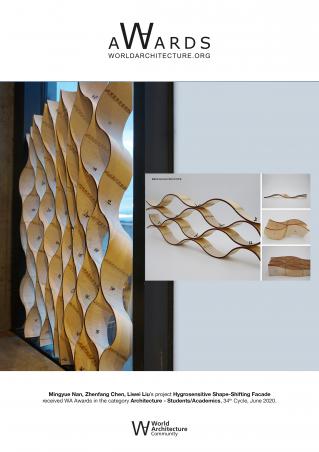

This shape-shifting façade demonstrates the aesthetic and functional potential of wood architecture. In addition, this system is environmentally friendly, as wood is one of the most natural and eco-friendly materials. Besides, this design is a passive system that is only actuated by the environmental factor that requires no energy. For the aforementioned reasons, this kinetic façade system has the potential to be broadly used in the future.

2019

2019

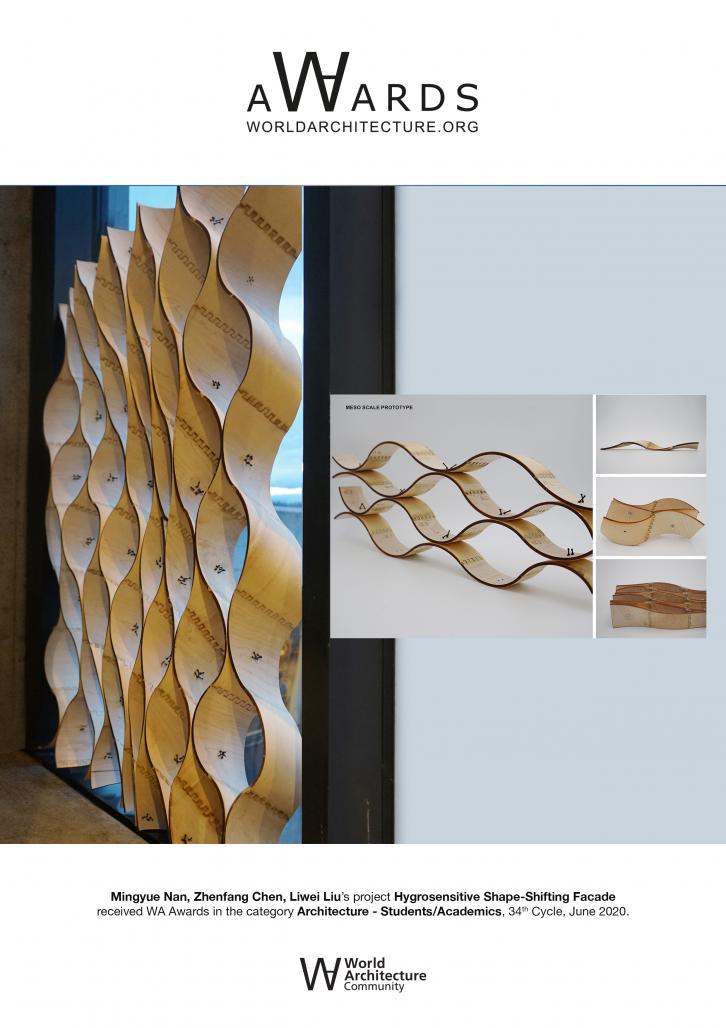

The final installation is a kinetic façade system composed of six pairs of wavy rows. The dimensions are: 10 inches in length and 67 inches in height (before shape-shifting) and 46 inches in length and 49 inches in height (after shape-shifting in the most extreme conditions).

The material we used was a maple-spruce bilayer (1/4’’ maple and 1/42’’ spruce).

The fabrication process constitutes eight steps: (1) equalizing maple and spruce pieces in a humidity chamber for 36 to 48 hours in order to increase the moisture content of the wood to the level required by the design, (2) laminating maple and spruce pieces with polyurethane glue, (3) vacuum-sealing the wood bilayers up to 24 hours to strengthen the adhesive, (4) laser-cutting the wood bilayers for all design-required pieces with finger joints, (5) gluing together the pieces in finger joints, (6) vacuum-sealing the glued rows up to 24 hours to strengthen the adhesive, (7) connecting rows by elastic string knots, and (8) dehumidification to ensure optimal shape-shifting performance.

Mingyue Nan

Zhenfang Chen

Liwei Liu

Instructor: Ehsan Baharlou

Hygrosensitive Shape-Shifting Facade by Mingyue Nan, Zhenfang Chen, Liwei Liu in United States won the WA Award Cycle 34. Please find below the WA Award poster for this project.

Downloaded 48 times.