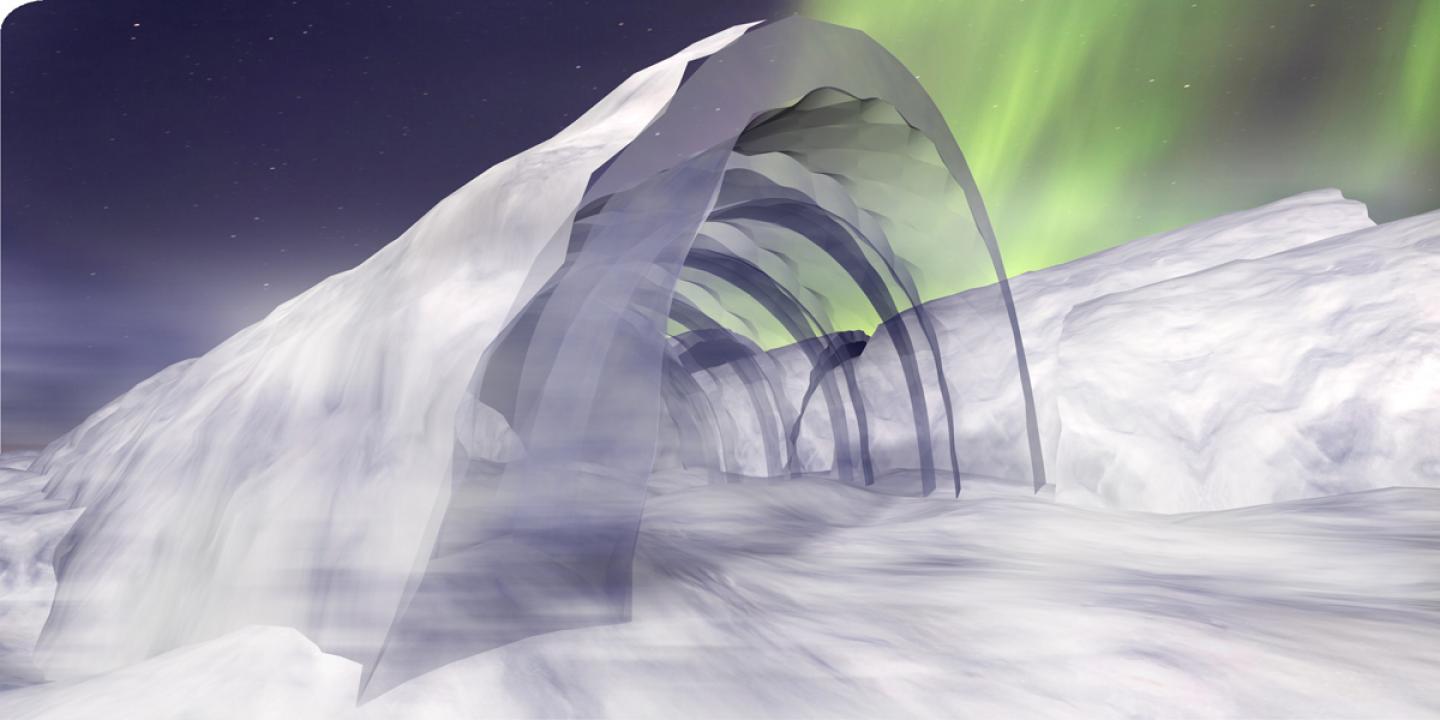

Antarctic In-Situ Resource Utilization, ISRU, uses high tech pneumatic formworks and ice, as a building material, to form structures in extreme environments.

The current Antarctic architectural typology consists of modulated containers on pilote, this is in response to the main design constraints; the katabatic wind driven snow deposition, the transport logistics, and the extreme cold. In the present model, large amounts of energy are spent on the transportation, construction and annual readjustment of these facilities. ISRU looks for a more holistic design approach to minimize material transport, material storage and material waste.

In accepting the inevitability of surface burial and the negative environmental ramifications, ISRU uses ice as structure in an overall structural configuration which manipulates snow deposition. By spraying a snow+ ice, snice, compound onto the pneumatic formwork, the purely tensile pneu forms the compressively strong ice. Inside the ice is a comprehensive thermal zoning strategy geared to the specific program. Using modular pneumatic formworks minimizes material transport time + costs and by using the abundant glacial ice, material waste is irrelevant.

In a comparison of the ISRU system with the standard typology for an ice core extraction facility, the in-situ resource utilization method saves 39% in transport volume while creating over 5x the floor area. These figures include the necessary supplementary materials to create a thermally controlled fully inhabitable environment.

OPENING

This project focuses on the development of snow/ice covered pneumatic systems, the design and development will focus on this air+ Ice technology in the context of Antarctic ice core extraction facilities; however this is more of an application than sole purpose. The daunting site constraints, climate, complex logistics teamed up with the necessary programmatic areas, i.e. interior heights of 10 meters for the drilling program to spans of 20 meters for airplane storage, make Antarctic architecture a formidable challenge. The facility will be built in sections to minimize the transported material, i.e. pneumatic modules. A quarter of the energy needed to melt the snow and power the construction process can be provided by the 24-hour summer sun using a small photovoltaic array. The building will provide a complete enclosure for the ice core camp activities allowing it to continue regardless of daylight and weather. The internal space of this enclosure is further subdivided by snow walls and additional thermal materials creating an overall thermal zoning strategy based on program. The relative abundance of material and construction ease affords more personal space as well as leisure and storage. This additional storage space is necessary to permit year round habitation and drilling. This space will not only facilitate a longer drilling season but also improve work efficiency by minimizing external unknowns. Once the drilling is completed and the ice core machinery removed, a scheduled five years, the facility can be abandoned and the building left to be buried by the relentless katabatic wind driven snow deposition, without a costly clean-up or removal program.

PROBLEM

Why Antarctic architecture is relevant:

The realities of climate change have increased scientific research and funding in the Polar Regions. This polar year marks the biggest ever expenditure, however doing Antarctic research averages at about 10:1 logistics to science ratio, with the building and maintenance of architectural facilities comprising the largest cost. In examining the British Antarctic Survey’s Halley bases as a case study to understand the strategies that have been used in the past, these two primary challenges emerge; transport logistics and Katabatic wind driven snow deposition. The cost of transportation, both financially and in terms of energy consumption, make inhabitable space extremely expensive

2006