This project, derived from the "Co-labora marañón" research, redefines traditional farms as innovative hubs within Colombia's cashew industry. It envisions these farms not just as spaces for cultivation but as experimental grounds that blend traditional practices with modern innovations. The aim is to explore new commercial avenues and redefine both the industry and the farmer's role in driving innovation.

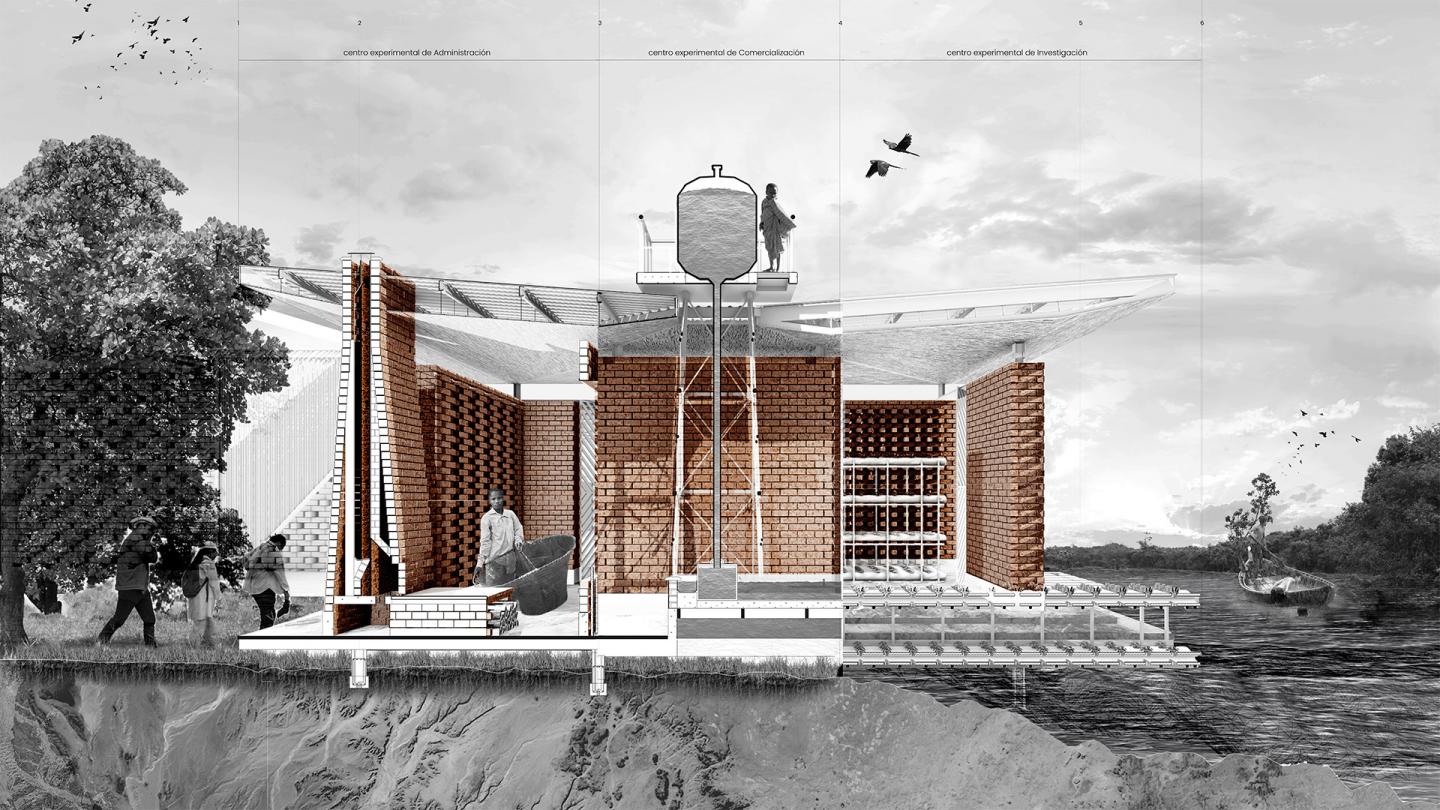

The project develops systems on material, projectual, and community scales, addressing key industry areas such as administration, research, adaptation, production, and commercialization. By integrating these areas, it promotes collaboration, technological integration, and the exchange of local knowledge, aiming to foster innovation and attract new growth agents to the region.

Strategically, the project designs five experimentation centers focused on cashew production, addressing challenges like monoculture, waste, and identity evolution. Utilizing cashew residues, which make up 75% of the nut, the project seeks to create new commercial niches, develop sustainable construction materials, and promote circularity, aligning with the Sustainable Development Goals (SDGs) as SDG 8 (Decent Work), SDG 9 (Industry, Innovation), and SDG 11 (Sustainable Cities).

Though this proposal focuses on departmental construction and development, it adheres to governmental plans and the guidelines set by the IGAC, as well as the principles of the new Territorial Ordinance Plan (TOP). Ultimately, it envisions a "cashew constellation" that unites farmers in a supportive network, highlighting the potential of local resources and traditional knowledge.

2024

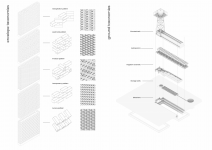

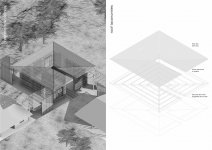

The project is divided into 5 taxonomies of experimentation centers. Following a common typology based on a 12 x 12 m grid (corresponding to a plot for a cashew tree), with a height of 4.5 m. Based on this, the taxonomies are adapted from material layers in the cover, envelope, and ground.

1. Experimental Administration Center: Area 144 m²

Program:

- Storage areas.

- Solar oven.

- Deep well.

- Absorption well.

- Unloading area.

A. Roof Detail:

Zinc sheet in trapezoidal panel

Roof beam with C-section

Thatched ceiling tied to structural beams

B. Rustic Solar Oven Detail:

2 mm mirror reflector

Polycarbonate tile cover layer

Smoke coating in aluminum over brick

Smoke chamber

Smoke shelf

Refractory brick

Ash pit

C. Thatched Ceiling Detail:

Exposed woven straw on sugarcane rails

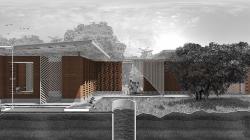

D. Facade Detail:

Compressed Cashew Block 200x100x100 mm (BBC)

Fine mortar joint of 24 mm

60 mm insulation

Aluminum cladding over BBC

E. Window Detail:

UPN aluminum 30 x 20 mm

Aluminum drip edge

Cashew block 200x100x100 mm

Fine mortar joint of 24 mm

Concrete base

F. Tie Beam Detail:

Mounting stirrups inside the beam

Concrete beam

Reinforcement under the footing

G. Absorption Well Detail:

River water pipe

Concrete dripper

Masonry with sealed joints

5 mm gravel

Concrete coating with 15 mm thickness

Concrete channel

H. Deep Well Detail:

Sanitary seal with concrete mortar

Clay and sand filling

Geomechanical filter

2. Experimental Research Center: Area 144 m²

Program:

- Seed bank.

- River port.

- Hydroponics.

- Scientific observation area.

A. Roof Detail:

Zinc sheet in trapezoidal panel

Roof beam with C-section

Thatched ceiling tied to structural beams

B. Door Detail:

Aluminum rail 30 x 40 mm

Pivot lock

150 x 370 mm cane frame

35 x 35 mm cane grid each

Clamping nut

Aluminum floor plate

C. Ceiling Detail:

Cane rails on structural metal beams

Exposed woven straw

D. Window Detail:

Cane rails 35 x 35 x 200 mm

Wooden board 20 x 35 x 200 mm

Aluminum window profile

Aluminum drip edge

Compressed Cashew Block 200x100x100 mm

Fine mortar joint of 24 mm

Concrete base

E. Tie Beam Detail:

Mounting stirrups inside the beam

Concrete beam

Reinforcement under the footing

F. Hydroponics Detail:

Structure in metal profile 3 x 3 x 80 mm

Perforated guadua 20 x 20 x 200 mm

Frame tied to floor plate 100 x 200 mm

Seedlings

3. Experimental Adaptation Center: Area 144 m²

Program:

- Permaculture zones in polyculture furrows.

- Central tank.

- Irrigation channels.

- Central cashew tree.

- Circulation and inspection corridors.

1. Roof Detail:

Zinc sheet in trapezoidal panel

Roof beam with C-section

Thatched ceiling tied to structural beams

2. Thatched Ceiling Detail:

Exposed woven straw on sugarcane rails

3. Floor Detail:

Concrete slab with 20 mm finish

Insulating panels

False concrete floor

Perimeter gravel border

Concrete channel

4. Floor Detail:

Concrete channel

Perimeter gravel border

Insulating panels

Vegetation

Mulch layer

Cultivation substrate

Soil

5. Planter Detail:

River water pipe

Concrete dripper

Masonry with sealed joints

Concrete pot with 5 mm finish

Asphalt membrane

Tar base

Vegetation

Mulch layer

Cultivation substrate

Soil

6. Channel Pool Detail:

Masonry with sealed joints

Concrete dripper

Aluminum drip edge

Compressed Cashew Block 200x100x100 mm

Fine mortar joint of 24 mm

Concrete base

Glazed tile coating

Concrete channel

4. Experimental Production Center: constructed area 144 m²

Program:

- Meeting and gathering area.

- Modular gardens.

- Collective garden.

- Interaction and collaborative work zones.

A. Roof Detail:

Zinc sheet in trapezoidal panel

Roof beam with C-section

Thatched ceiling tied to structural beams

B. Thatched Ceiling Detail:

Exposed woven straw on sugarcane rails

C. Facade Detail:

Compressed Cashew Block 200x100x100 mm (BMC)

Fine mortar joint of 24 mm

Non-structural concrete module 200 x 100 x 100 mm

Fine mortar joint of 24 mm

Concrete base

Modular wooden branch

D. Tie Beam Detail:

Mounting stirrups inside the beam

Concrete beam

Reinforcement under the footing

E. Modular Garden Detail:

Wooden branch structure

Tied with rope

Wooden board pot

F. Planter Detail:

River water pipe

Concrete dripper

Masonry with sealed joints

Concrete pot with 5 mm finish

Asphalt membrane

Tar base

Concrete retaining wall

Vegetation

Mulch layer

Cultivation substrate

Soil

G. Retaining Wall Detail:

Concrete screen

Waterproofing with asphalt paint

Geotextile

Soil

Concrete footing with heel

5. Experimental Commercialization Center: Area 144 m²

Program:

- Elevated tank and lookout.

- Livestock trough

- Traveler trough.

- Commercial nursery.

A. Roof Detail:

Zinc sheet in trapezoidal panel

Roof beam with C-section

Thatched ceiling tied to structural beams

B. Thatched Ceiling Detail:

Exposed woven straw on sugarcane rails

C. Window Detail:

UPN aluminum 30 x 20 mm

Aluminum drip edge

Aluminum window profile

2 mm wooden board

Compressed Cashew Block 200x100x100 mm

Fine mortar joint of 24 mm

Concrete base

D. Tie Beam Detail:

Mounting stirrups inside the beam

Concrete beam

Reinforcement under the footing

E. Elevated Tank Detail:

Cylindrical tank 90 x 130 mm

Metal railing

Concrete plate

Metal access cover

Water outlet pipe

Metal structure

F. Well and Trough Detail:

Water inlet pipe

Inspection cover

Cutoff valve

Water reserve

Superficial concrete channel

Inspection cover

Concrete reserve tank

Additionally, a taxonomy of connection between the experimentation centers is developed. This is a circulation area of 3 x 6 meters where the walls of each experimental center extend to form a common exchange zone for the uses and activities of each one.

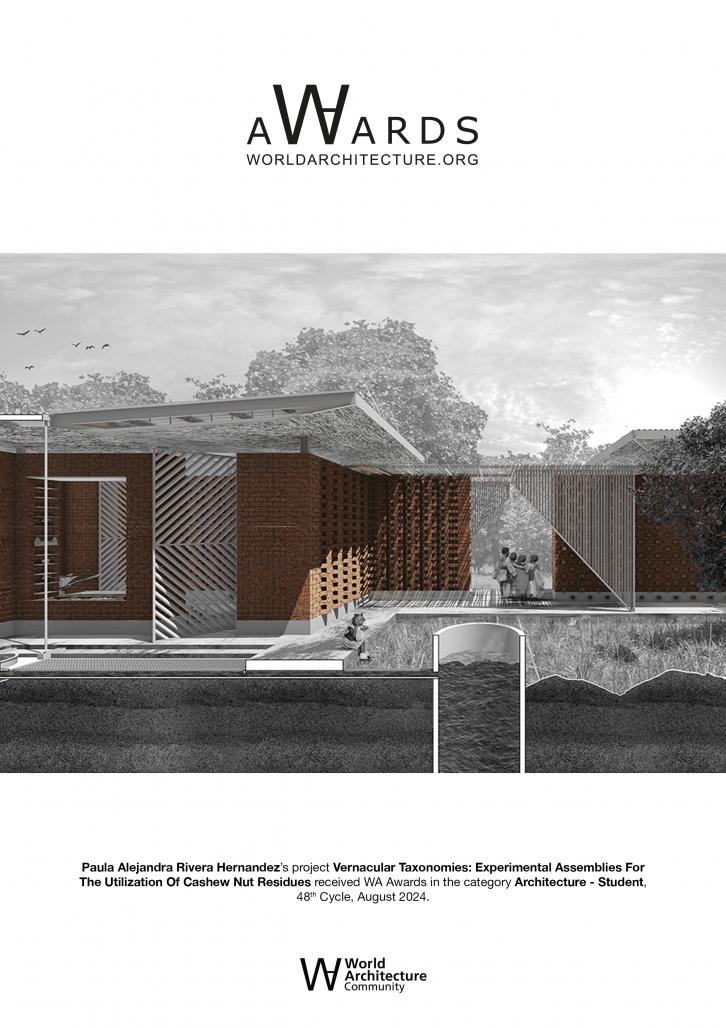

Designer: Paula Alejandra Rivera Hernandez

Thesis Directors: Daniela Atencio and Claudio Rossi

Vernacular Taxonomies: Experimental Assemblies For The Utilization Of Cashew Nut Residues by Paula Alejandra Rivera Hernandez in Colombia won the WA Award Cycle 48. Please find below the WA Award poster for this project.

Downloaded 0 times.

Favorited 2 times