The primary intention of this project is to fundamentally challenge and provide a viable alternative to the prevailing linear "take-make-dispose" model that dominates the construction industry. We specifically address the problem of irregular off-cut wood, a vast and undervalued resource stream that is typically downcycled or sent to landfill. The core deficiency of traditional recycling methods is that they are often experience-based, not easily replicable, and fail to successfully reintegrate geometrically complex wood into high-value production, merely delaying its eventual disposal. Our goal was to develop a systematic, reproducible, and technology-driven framework that treats this "waste" as a primary input material, thereby truly closing the loop and promoting a circular economy in the Architecture, Engineering, and Construction (AEC) industry.

Conceptually, the project is built on a paradigm shift away from a conventional top-down design process, where ideal materials are sourced for a preconceived form. Instead, we intended to create and validate a bottom-up, "material-first" methodology where the specific, intrinsic characteristics of the available reclaimed materials directly inform and generate the design possibilities. This intention is to move beyond the limits of designing only with regularly shaped, easily documented resources. The project establishes a new workflow that begins with the creation of a comprehensive digital database of the physical materials. This digital inventory becomes the foundation for a design process that is not about imposing a form onto a material, but about discovering the latent structural and aesthetic potential held within the material itself.

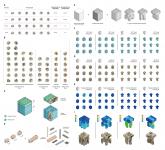

To achieve this, our intent was to leverage a suite of integrated technologies as enablers of this new design philosophy. The framework was designed to replace subjective, experience-based approaches with an objective, data-driven, and systematic workflow. 3D scanning is used to capture the complex reality of each wood piece ; voxel-based packing and the Wave Function Collapse (WFC) algorithm are used to computationally explore assembly and aggregation possibilities ; and Finite Element Analysis (FEA) is used as a crucial, quantitative method for pre-construction validation of structural performance. The intent of this technological integration is to create a robust and reliable process that is both scalable and replicable by others in the industry.

Ultimately, the project intends to demonstrate that this data-driven workflow can lead to the creation of structurally sound, functionally useful, and aesthetically compelling architectural elements, from furniture to entire buildings. The resulting forms—seen in the stool, column, and "Primitive Hut" pavilion—are not arbitrary but are an authentic expression of the computational logic and the unique geometries of the wood pieces used. By showcasing a repeatable and scalable process, the ultimate intention is to provide the AEC industry with the theoretical guidance, technical assistance, and practical tools to embrace waste as a primary resource. We aim to inspire a broader industry shift towards sustainable practices, proving that environmental responsibility and innovative design can be, and should be, mutually reinforcing.

2023

Project Framework: The project is underpinned by the Sustainable Building Design and Construction (SBDC) framework, a three-stage workflow:

1. Material Reclamation System (MRS): A system for creating a digital database of reclaimed wood.

2. Structural Generation and Assessment System (SGAS): A computational system for design generation and structural analysis.

3. Fabrication: Physical assembly of the generated designs.

Materials & Data Acquisition:

Source: Irregular off-cut wood from various sources, including sawmills and demolition sites. The database includes hardwood and softwood species with varying properties.

3D Scanning: Multiple technologies were employed for digitizing wood pieces based on scale:

Small-Scale (<200mm>700mm³): Photogrammetry using DJI Mavic Pro drones.

Database Parameters: The digital inventory recorded geometric topology, wood type, dimensions, weight, age, recycling grade, moisture content (measured with a BENETCH-GM630 meter), density, and material proportion (e.g., % wood, % MDF, % nails).

Design & Analysis Software:

Voxelization: Irregular wood geometries were packed into standardized digital blocks (voxels). An optimal voxel size of 100x100x100 mm was determined, achieving an average internal filling rate (IFR) of 42.45%.

Algorithmic Design: The Wave Function Collapse (WFC) algorithm was used to intelligently assemble voxels into larger structures based on defined adjacency rules.

Structural Analysis: Finite Element Analysis (FEA) was used extensively to verify the structural integrity of the generated designs before fabrication, identifying stress behaviour and maximum load-bearing areas.

Fabrication & Case Studies:

Assembly: Fabrication involved a combination of craftsmanship, AR-assisted assembly, and explorations into future robotic assembly.

Prototypes: The framework was verified through the construction of physical prototypes at different scales:

Furniture Scale: A stool with a boundary size of 300x300x400 mm.

Component Scale: A structural column with a boundary size of 300x300x1600 mm.

Architectural Scale: The "Primitive Hut," a pavilion demonstrating the integration of voxel-volumetric, panel, and surface systems. The column was assembled at the School of Architecture, The Chinese University of Hong Kong

Boyuan Yu, Jianing Luo, Yi Shi, Mingming Zhao, Adam Fingrut & Lei Zhang