The Crafted Workspace

This little town in Tamil Nadu gained its repute as the hub of export oriented home textile industry in India. It’s a hot dusty town, steeped in tradition, but geared towards modernity. The dying of colored yarn, weaving and stitching of fabric, cushions and table linen, is a home industry conducted in the courtyard of village homes in and around Karur. The products of this village industry are gathered and transported, often by the traditional bullock cart, to the temples of modernity – the checking and packaging factories, from which the product is shipped out to the international retail market. The factory then takes the transitional role between the local and the global. Despite the hot dry climate and deeply historic and religious character of this town, Karur’s factories represent a “ me too” attitude with glass facades and Doric columns, - supposed sentinels of globalization

Synergy lifestyles wanted us to build a comfortable environment for their factory workers. Our need to create a cocoon which would protect the micro environment within from the harsh environmental conditions outside like heat and glare helped us derive our basic architectural shell structure that would be a joy to work in inspite of the hot and dry climate.

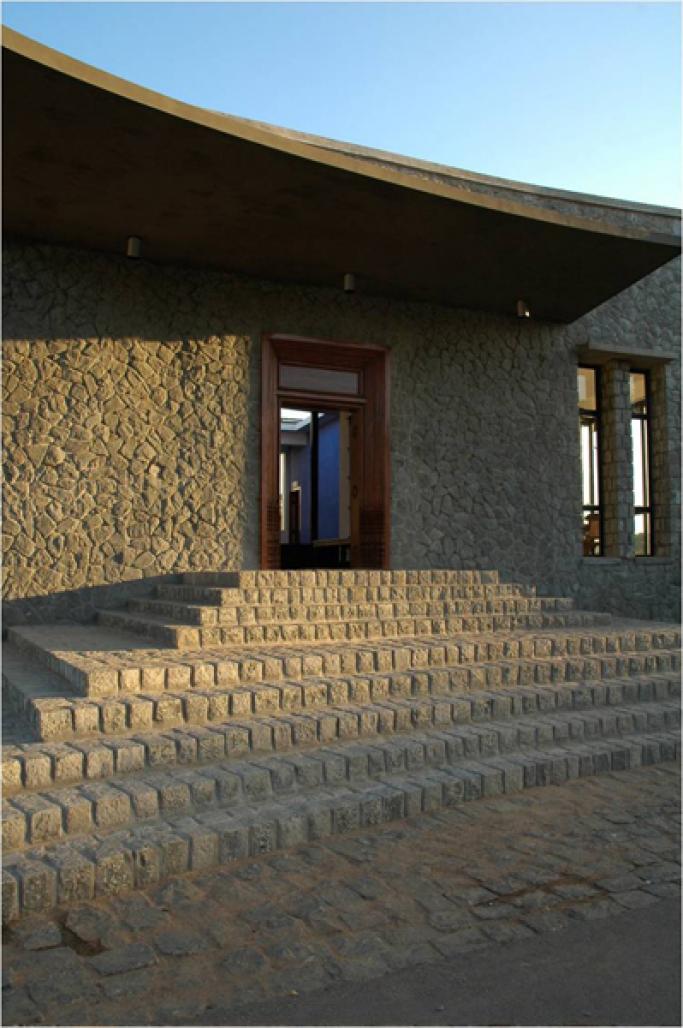

We studied the local architecture and climate, and developed a building that is linked with courtyards, small and big, and passive energy saving building technologies. We discovered that this little town had an interesting history of gable walls, a local stone quarry and many other traditions of country-wood joinery for doors, an entire village that specializes in metal hardware for locks and hinges, etc. Even the flooring, the terracotta cement tiles, come from the local Chettinad area, as did the wonderful carved wooden main door.

The entire building has been cocooned in 18” thick random rubble masonry walls which being a good insulator of heat helped in cordoning off excessive heat and had an added advantage of not requiring any plaster or paint over the exterior surface. We chose to go with a vaulted roof over clear storey’s that allow shaded north-south light.

The roof was built using hollow terracotta blocks which were fitted within a grid of precast RCC ribs, which were spanned between semi-circular beams of steel. A thin cement screed with a china mosaic finish over it completed the roof construction, making it economical, light-weight, and cutting out several degrees of heat gain. Several small and large courtyards on the west reduce afternoon heat gain by providing a vegetation buffer. The west also brings in the winds, which are filtered by the plants and trees of the courtyard.

The attempt has been to build locally for a global context, using local materials, labour and technology, to create a building that is very much part of a global market, functionally and aesthetically. However, our ultimate payback has been the end user’s response wherein. “The production has risen two-fold” !

2003

2004

PROJECT AREA : 30,000 Sq.ft.

MATERIALS:

Stone (Random rubble in local quarry stone) load bearing vaulted structures with clear stories combined with RCC structures, Hollow clay Hourdi blocks for roof, Flooring in Attangudi cement glazed tiles from Chettinad and other local stones

DESIGN TEAM:

Shimul Javeri Kadri,

Vaishali Shankar,

Pushpinder Kaur Dhuna

Favorited 3 times