This research attempts to create an open-ended timber system that can form different architectural elements by applying the notion of generative design, the materiality of wood, and digital fabrication.

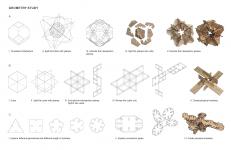

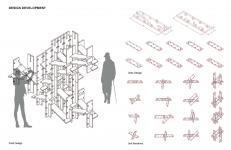

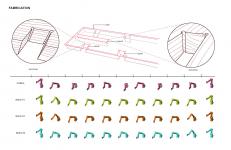

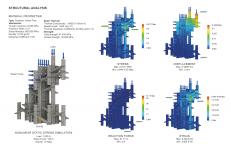

A cross-referencing method, which includes geometry study, material study, fabrication test, and structure analysis, is developed by this research collective to serve as the driving force of this project. The feedback among each approach provides guidelines for future research and practice. The geometry study shapes the form-searching process and provides theoretical support for the unit design by understanding the physical properties of different geometries and connection methods. The material study is conducted on the aspect of material dimension, grain orientation, stiffness, and elastic properties. Three key issues come from the fabrication test: milling speed of the current robot setup limits the scale of the final structure, the dimension limitation and maximum load of a robot affects the form and size of the unit, the accuracy of robotic fabrication and bending behavior of wood material during the change of air humidity require more tolerance to be considered during the unit design process. The final design is also guided by the feedback of structure analysis, which centers around structural performance. With this methodology, this project integrates the design and the materialization process to a responsive loop rather than the conventional linear process which prioritizes the design to the materialization.

2021

2021

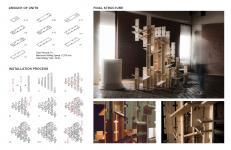

Dimension: 8'(H) x 10'(L) x 2'(W)

Material: Southern Yellow Pine(Lumber)

Units Dimension: 1” x 7” x 28"

Ziwei Shen, Student, School of Architecture, University of Virginia

Yuwen Zhou, Student, School of Architecture, University of Virginia

Chris MacDonnell, Student, School of Architecture, University of Virginia

Ehsan Baharlou, Dr. -Ing, Instructor, School of Architecture, University of Virginia