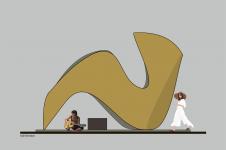

This space is intended as a pavilion for rest and community gatherings for the villagers and the tourists.

The village of Darak is located 170 kilometers from Chabahar . As you travel through this area of Iran, you reach a point where the sea surrounds the sand dunes of the desert, which attracts visitors from all over the world.

The topography of sand dunes in these areas adds spectacular attractions to this area. given this amazing sandy desert, our best design option is to be inspired by the nature.

We designed this Project considering the traditional architecture of the region, which is affected by the maximum sunlight and high temperature during the day.

Furthermore, we were inspired by the curvature and fluidity of sand dunes, in addition to the traditional construction methods for the fictile embowed houses.

Our design team has utilized an innovative construction method using 3D printing, which can use endemic materials, such as clay and sand, with a layer-by-layer method and create the form without any harm or disruption to the environment and the natural surrounding.

We integrated the design of a dome-shaped shell with vaulted openings for Stability.

2020

2020

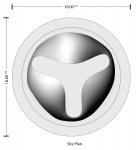

The plan dimensions of 18 by 18 square meters (including the perimeter of the design) is designed in a circular platform of 10/m height for stability and strength.

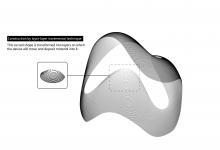

Construction by layer-layer incremental technique.

This curved shape is transformed into layers on which the device will move and deposit material into it.

Bringing Robotics to the Construction Site to Manufacture the Future.

Combining technological advances in robotics (cable robot and drones), natural materials and CAD/CAM software, the aim of the project, which will be presented at Construmat 2021 In the village of Darak, is to bring automation to the construction site, as well as allowing the production of high-performance buildings and their monitoring in real-time during the construction.

The 3D Printing System presented in On Site Robotics is introduced to 3D print large-scale construction parts, and even small-scale buildings, made from natural materials. This system includes the cable robot Cogiro with an integrated CNC control, which is able to automate the movement of the 3D extruder with precision.

The system also integrates a curved, sand-based arch form based on Iran's traditional architecture project, integrating biodegradable, recyclable, and integrated areas. In addition, a custom script integrated into CAD software allows translating complex three-dimensional design forms into robotic paths.

The project focuses on the behavior of the soil for 3D printing when mixed with other ingredients (Such as sand), towards a better understanding of the material, and potential composites.

Lead Architects :Amir Armani Asl & Kiana Ghader

Project Credits: A Architects Office